Safe elevator with brake in lift car

一种安全电梯、制动器的技术,应用在建筑物内的电梯、升降机、运输和包装等方向,能够解决拖长电梯交付使用的时间、影响住户正常生活、施工工期长等问题,达到缩短施工工期、缩短工期、提高安装质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one: if Figure 6 As shown, the elevator described in the present embodiment comprises a hoistway wall 8, a car 2, and a counterweight 5. The car 2 runs in the hoistway wall 8, and the car 2 uses a wire rope 254 to pass through the traction sheave 112 and the guide pulley 121 and the counterweight 5. Heavy 5 connected.

[0034] This embodiment adopts the traction and drag mode of the existing elevator. The structure of each part of the elevator is the same as that of the existing traction elevator. The difference is that a main shaft 34 is installed on the car, and a car brake is added on the main shaft 34. 37. In order to ensure that the car brake 37 can work effectively, the sliding connection between the hoistway wall 8 and the car 2 is changed to a rack and gear meshing connection.

[0035] Such as Figure 12Shown, a kind of car is provided with the safety elevator of brake, comprises hoistway wall 8, car frame 21 and the car guide rail 110 that is loca...

Embodiment 2

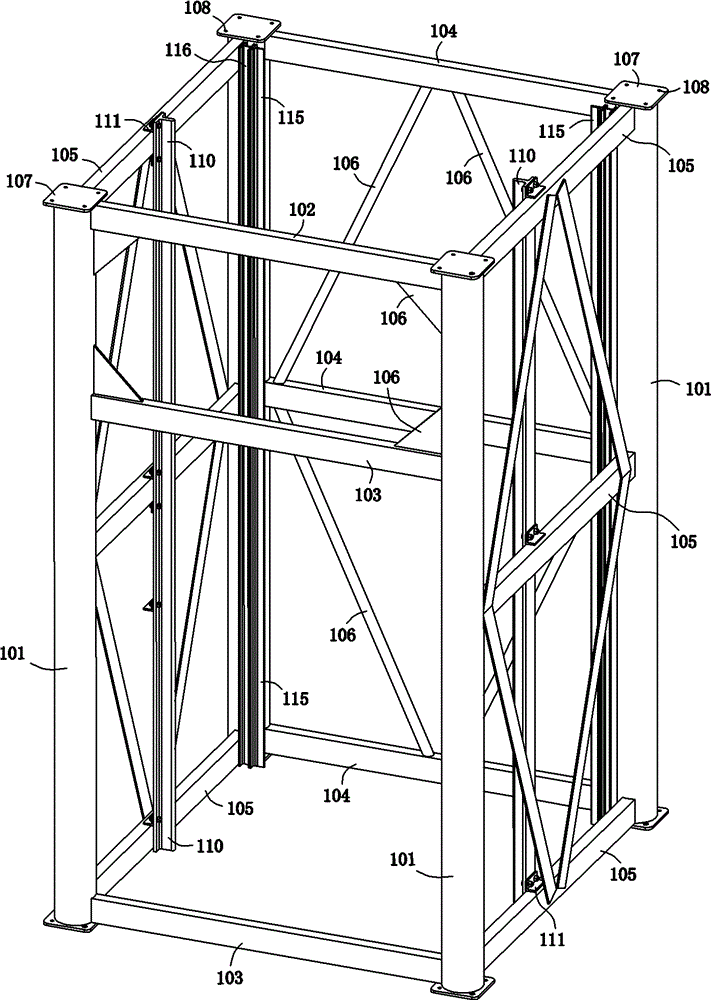

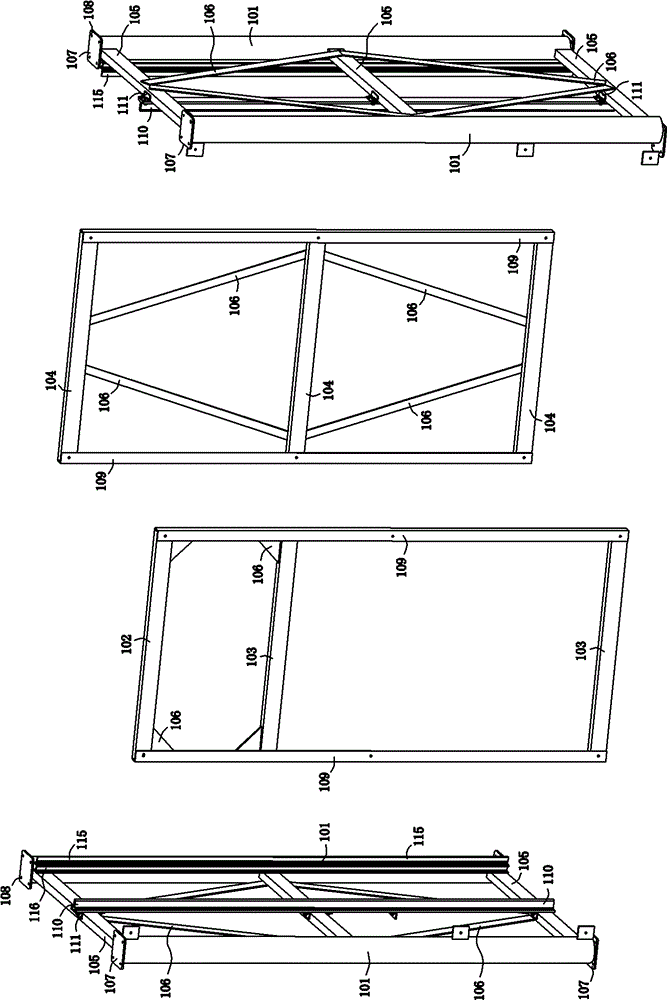

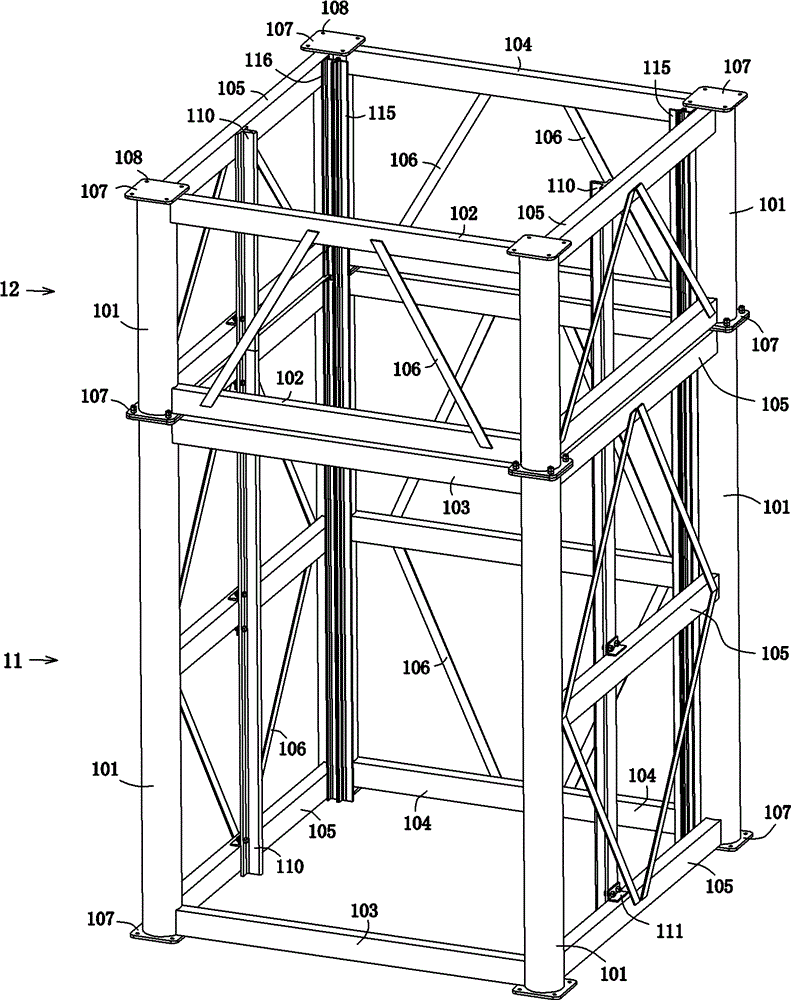

[0040] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that the hoistway wall 8 is improved, and the hoistway wall 8 of this embodiment adopts a metal frame hybrid structure. Such as Figure 7 As shown, the hoistway wall 8 of this embodiment includes a well tower and a pit body 13. The well tower is assembled by laminating two or more steel structure derricks 1 through high-strength bolts according to the number of floors where the elevator is installed. Formed, the derrick at the bottom of the well tower is called the bottom derrick, and the bottom derrick is horizontally fixed on the bottom pit body 13 by high-strength bolts.

[0041] Such as figure 1 As shown, the derrick 1 includes 4 columns 101, 3 rear beams 104 and 3 left and right side beams 105 respectively. A connection seat 107 is provided, and four connection holes 108 are arranged on the connection seat 107 (in other embodiments, the number of connection holes 108 may also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com