Reamer with hydraulic characteristic for dredger

A technology of hydraulic characteristics and dredgers, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of increased cost and reduced engineering efficiency, and achieve high work efficiency, simple structure, and reduced sediment leakage The effect of reamer's chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

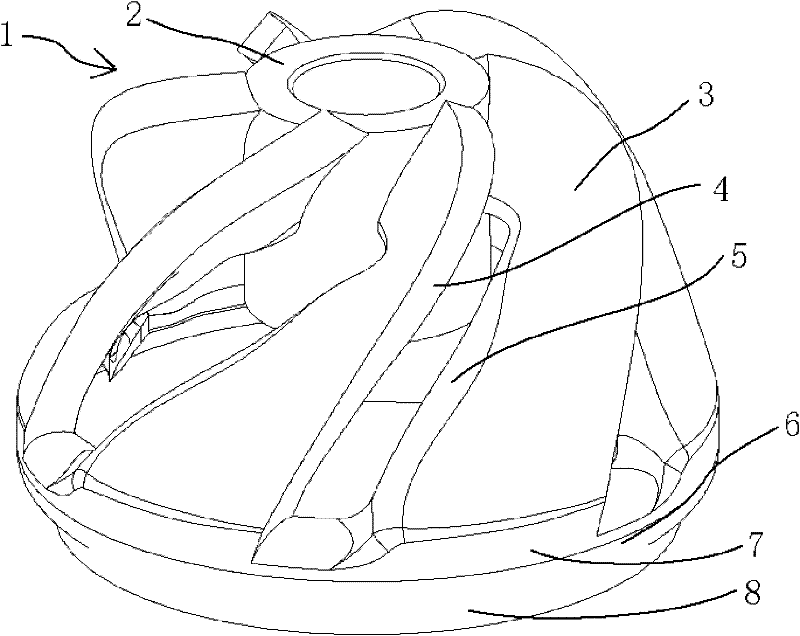

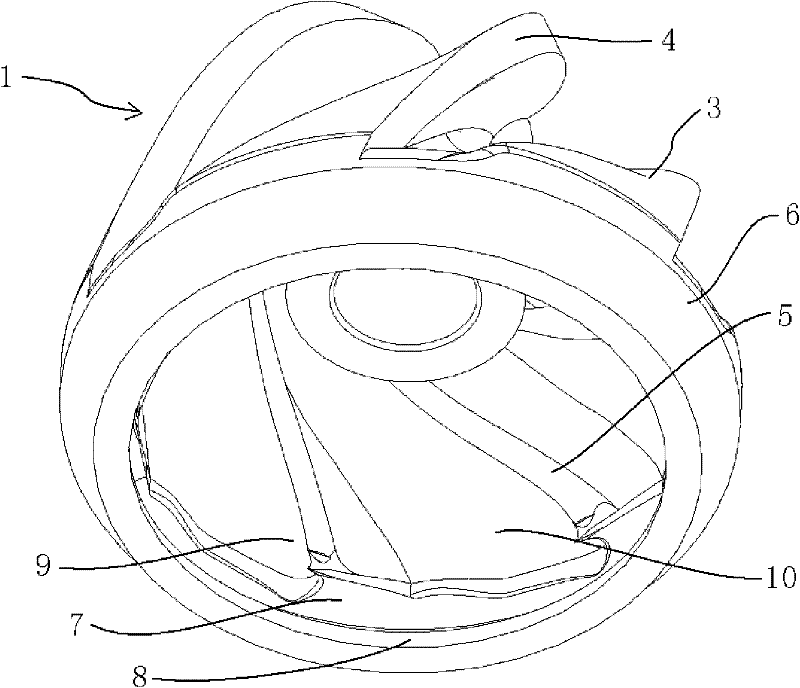

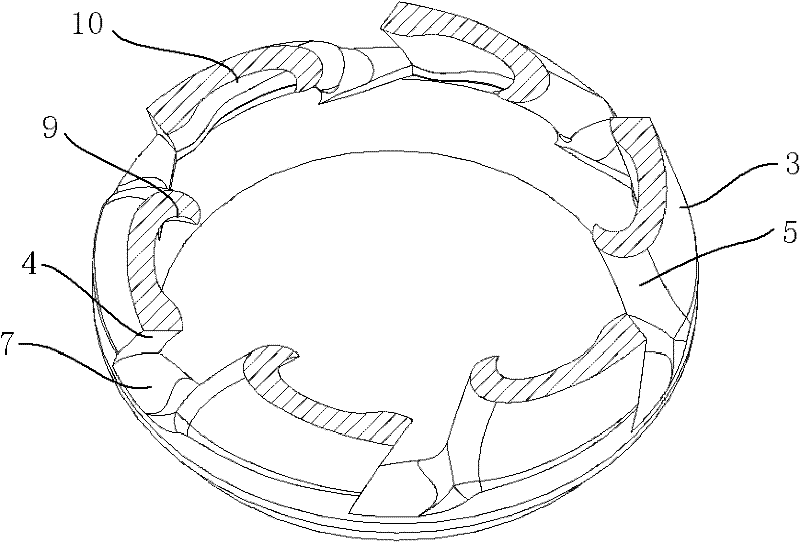

[0028] Reference attached Figure 1 to Figure 5 .

[0029] A reamer with hydraulic characteristics for a dredger, comprising a knife arm, a hub and a big ring. The knife arm 3 has a recess 10 on the inside, the big ring 6 has an inner ring cavity, and the inner recess 10 of the knife arm extends to the ring cavity of the big ring 6 , Plays the role of diversion of mud flowing in the direction of the large ring 6. The inner edge 4 of the knife arm 3 has an arc groove 9. The inner ring cavity structure of the big ring 6 is a wide upper part 7 of the big ring, the lower part 8 of the big ring is narrowed into a bell-shaped cavity structure, and the wide ring cavity of the upper part 7 is received at the end of the knife arm groove 9. Tooth seats are arranged on the outer edge of the knife arm 3, and each tooth seat is equipped with a detachable knife tooth.

[0030] The specific implementation process of the present invention:

[0031] A reamer 1 with hydraulic characteristics for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com