Hidden frame glass curtain wall with steel joist frame

A technology of hidden frame glass curtain wall and steel keel, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of poor spraying effect, difficult installation, waste of materials, etc., and achieve the effect of low cost, safe and reliable use, and reduced installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

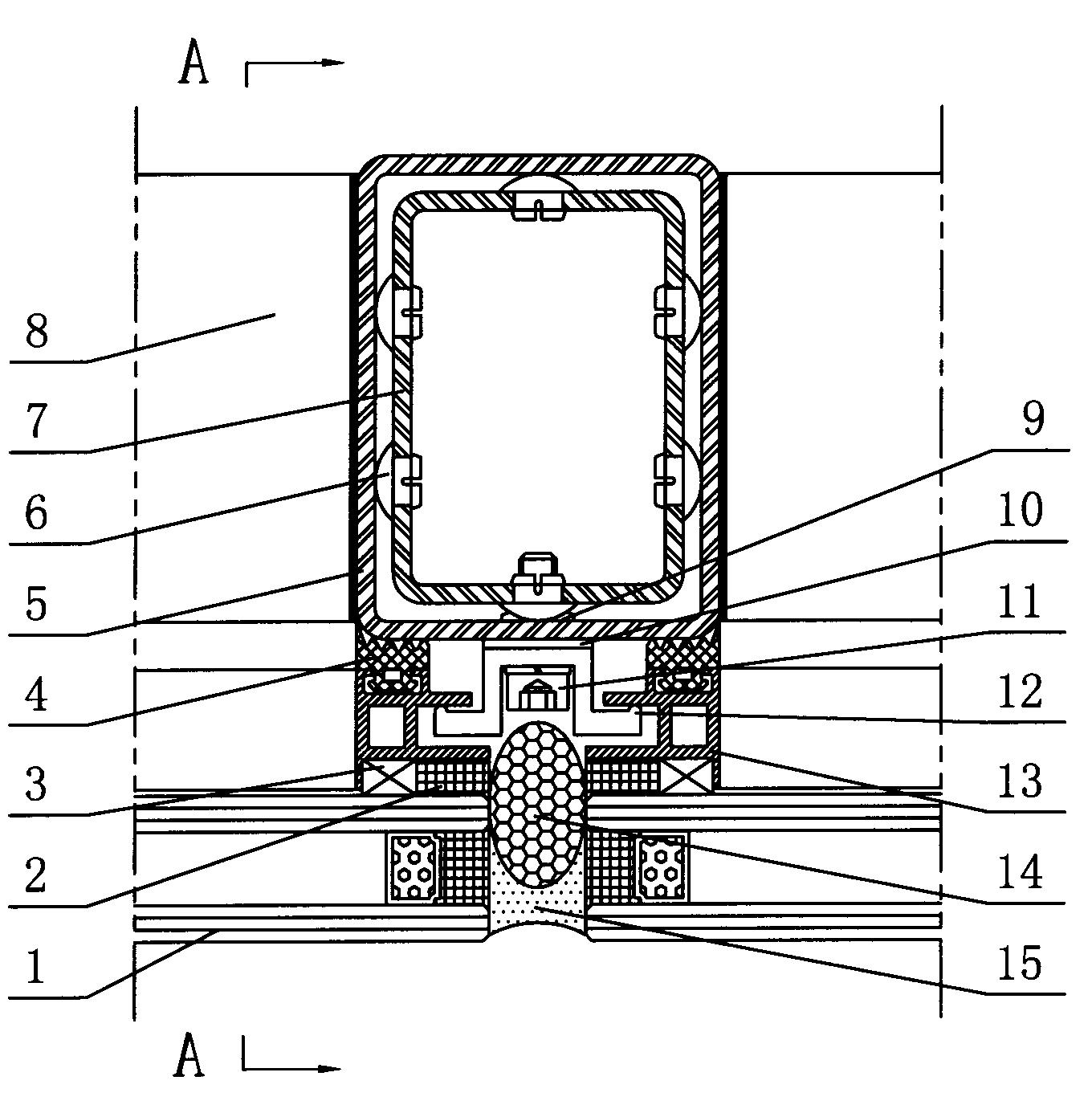

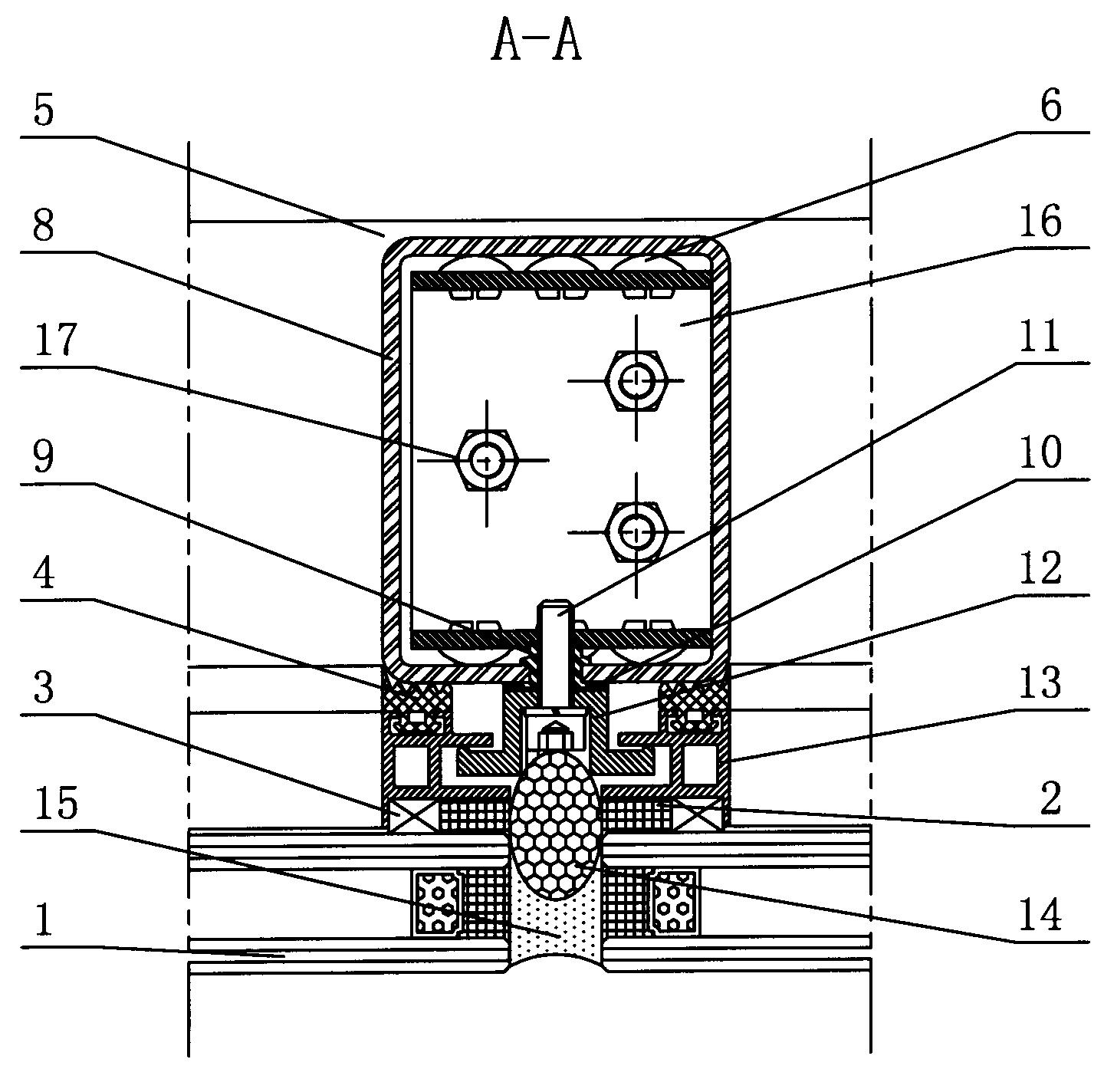

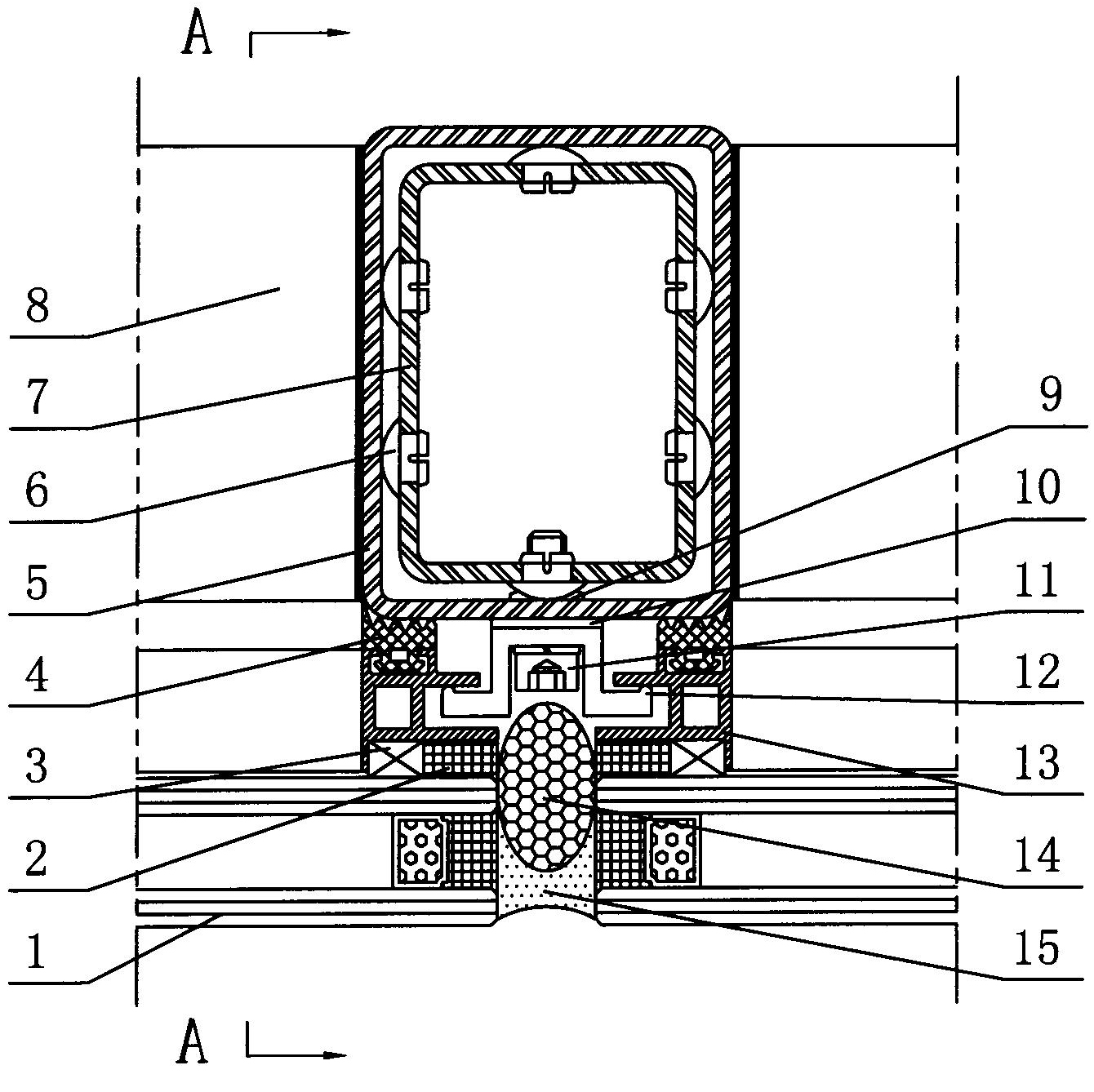

[0021] according to Figure 1~2 The specific structure of the present invention will be described in detail. The steel keel frame hidden frame glass curtain wall includes a steel keel frame, a glass surface material 1 and a connecting assembly for fixing the glass surface material 1 to the steel keel frame through a glass attachment frame 13 . Wherein the steel horizontal frame 8 and the steel mullion 5 in the steel keel frame adopt the rectangular steel profiles formed by cold working and rolling of thin-walled high-quality steel plates. This rectangular steel profile has small rounded corners and beautiful appearance. It can be treated with anti-corrosion inside and outside, and the spraying effect is good. The steel horizontal frame 8 and the steel mullion 5 are plugged together through the steel horizontal frame ferrule 16 . The steel horizontal frame ferrule 16 is a U-shaped steel profile made of rolled steel plates consisting of two facades and a bottom surface. The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com