Main drive mechanism of six-arm cutterhead for shield machine

A main drive and shield machine technology, applied in the direction of electric components, electromechanical devices, control mechanical energy, etc., can solve the problems of hydraulic oil leakage and pollution of the working environment of the machine, and achieve the effects of low noise hazard, high efficiency, and low starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

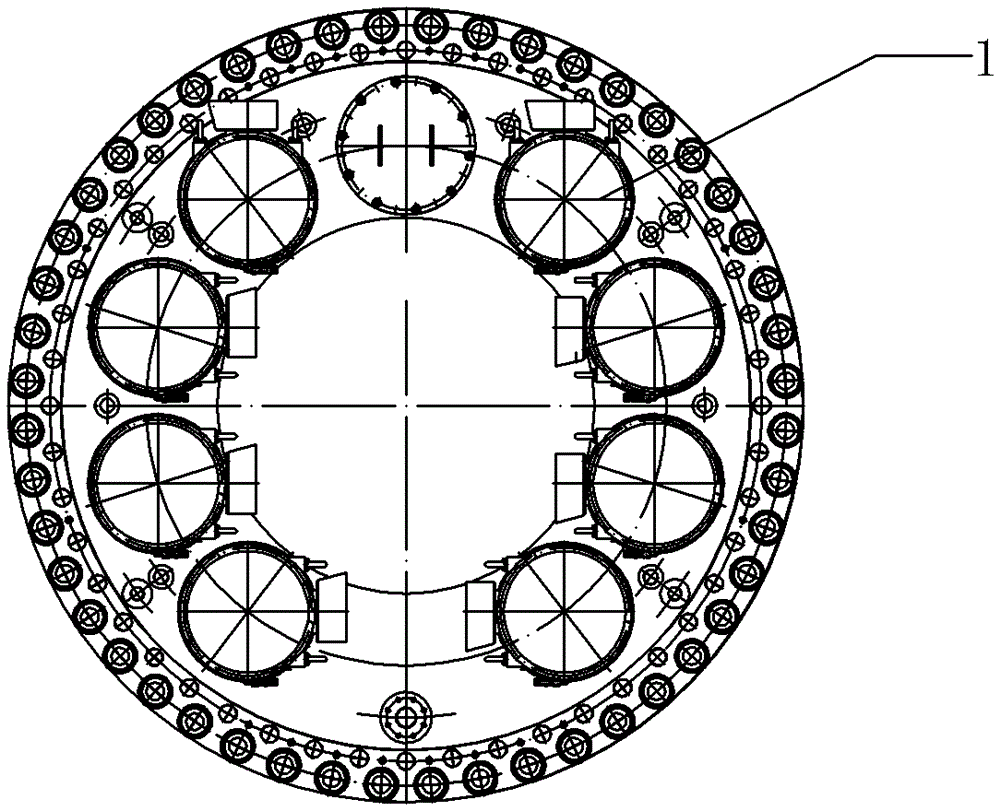

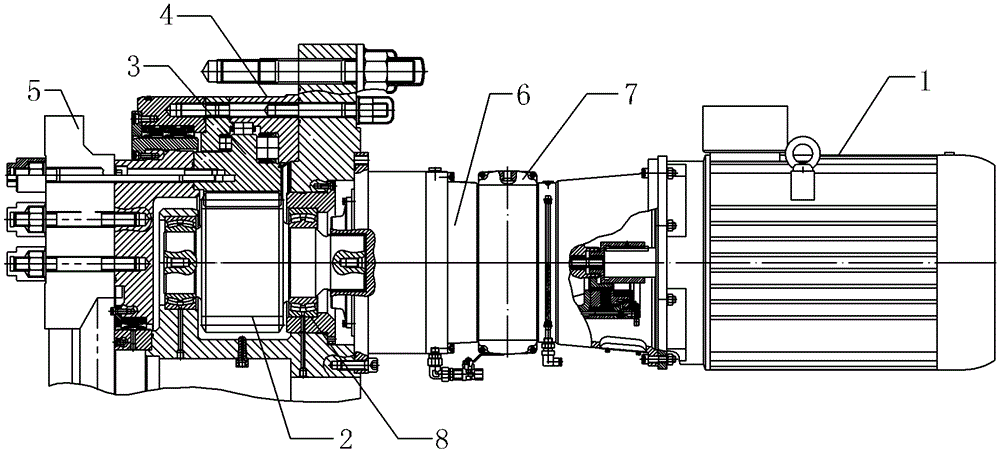

[0022] figure 1 and figure 2 Constitute the specific embodiment 1 of the present invention.

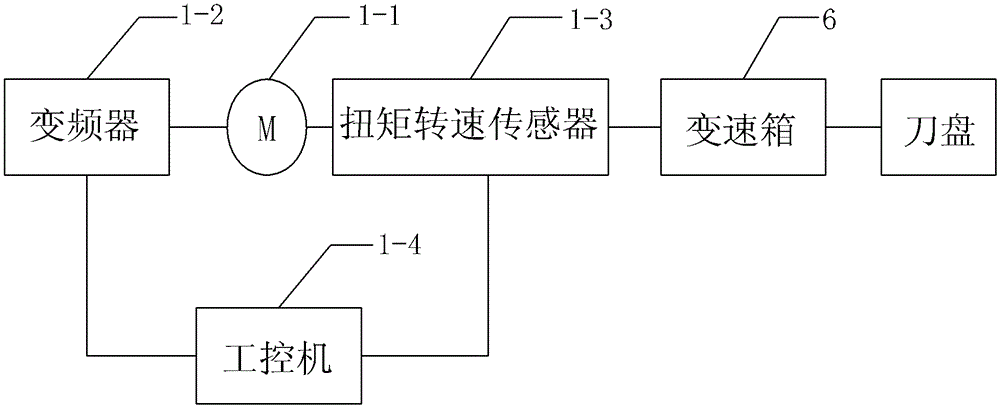

[0023] refer to figure 1 and figure 2 , this embodiment includes a shield machine cutter head and a main drive mechanism, the main drive mechanism is mainly composed of several synchronous frequency conversion motors 1, gear devices 2 and main bearings 3, the output end of the frequency conversion motor 1 and the input of the gear device 2 end tightly connected, the output end of the gear device 2 is connected with the main bearing 3 and drives the main bearing 3 to rotate, the main bearing 3 is connected with the cutter head of the shield machine through the connecting flange 4, and the upper part of the main bearing 3 A sealing assembly 5 is provided; the synchronous variable frequency motor 1 has a brake, and the synchronous variable frequency motor 1, the gear device 2 and the main bearing 3 are connected to form a detachable integrated structure. A gearbox 6 and a cooling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com