Electrode group pressure and acid absorption quantity measurement method for absorptive glass mat (AGM) lead-acid storage battery

A technology of lead-acid battery and measurement method, which is applied in the measurement of pole group pressure and acid absorption, and in the field of lead-acid battery manufacturing, which can solve problems such as battery performance impact, unpredictable pole group pressure, and battery quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

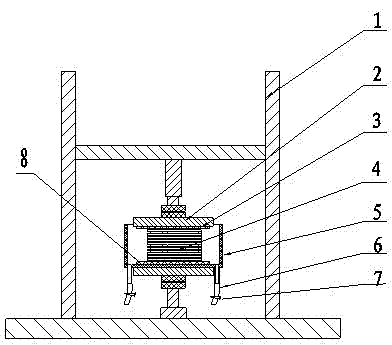

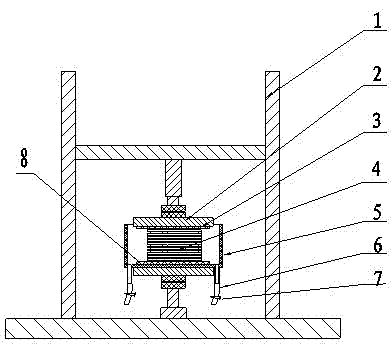

[0022] The method of the invention simulates the state of the pole group in the battery, and measures the pressure change of the pole group in a dry state and a wet state (after adding acid). see figure 1 , The required test equipment includes a tensile testing machine 1, a test briquetting block 2, a test container 5, an upper backing plate 3, and a lower backing plate 8. The area of the test pressing block, the cross-sectional area of the test container, and the area of the upper and lower backing plates need to be larger than the surface area of the tested pole group. The test container 5 is a flat-bottomed plastic shell, the bottom of the test container is provided with an acid discharge pipeline 6, and an acid discharge valve 7 is provided at the acid discharge pipeline.

[0023] still refer to figure 1 , the method of the present invention is described in detail below in conjunction with a specific embodiment:

[0024] (1) Prepare the test briquette, wrap the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com