Optimized design method for hydraulic cylinder supporting seat of cover carriage based on response surface

A technology for optimizing design and support seat, applied in the direction of calculation, special data processing applications, instruments, etc., can solve problems such as stress concentration, and achieve the effect of large time cost, high calculation accuracy, and shortened development and design time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

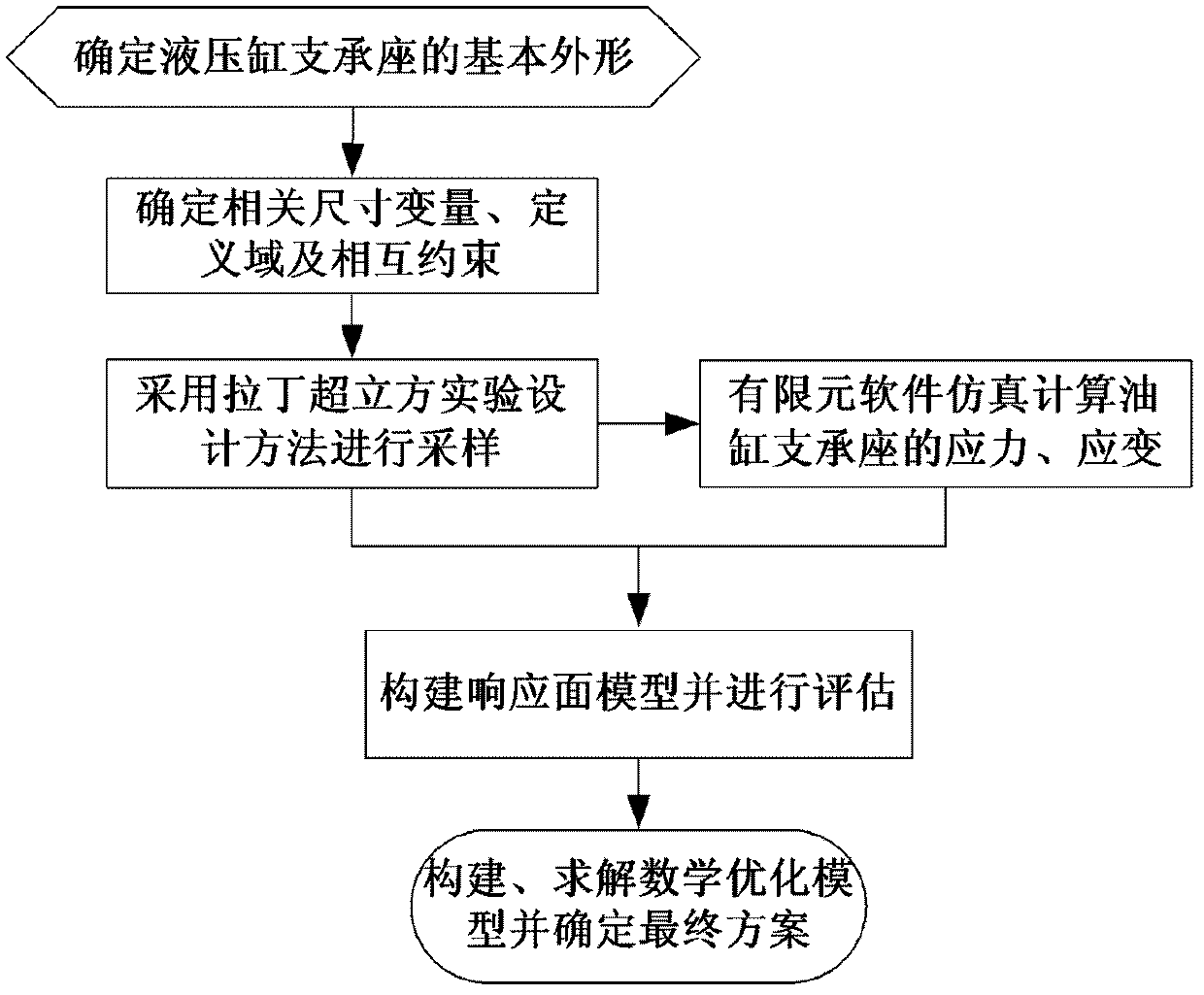

[0043] The optimal design method of the support seat of the hydraulic cylinder of the uncapping machine based on the response surface provided by the present invention, its process is as follows figure 1 As shown, the steps include:

[0044] 1. Determine the basic shape of the hydraulic cylinder support seat;

[0045] On the basis of satisfying all the functions of the supporting seat of the hydraulic cylinder of the uncapping machine, analyze the force and stress distribution of the entire supporting seat, determine the shape and preliminary dimensions of the supporting seat according to the design specifications and experience, and complete the preliminary conceptual design.

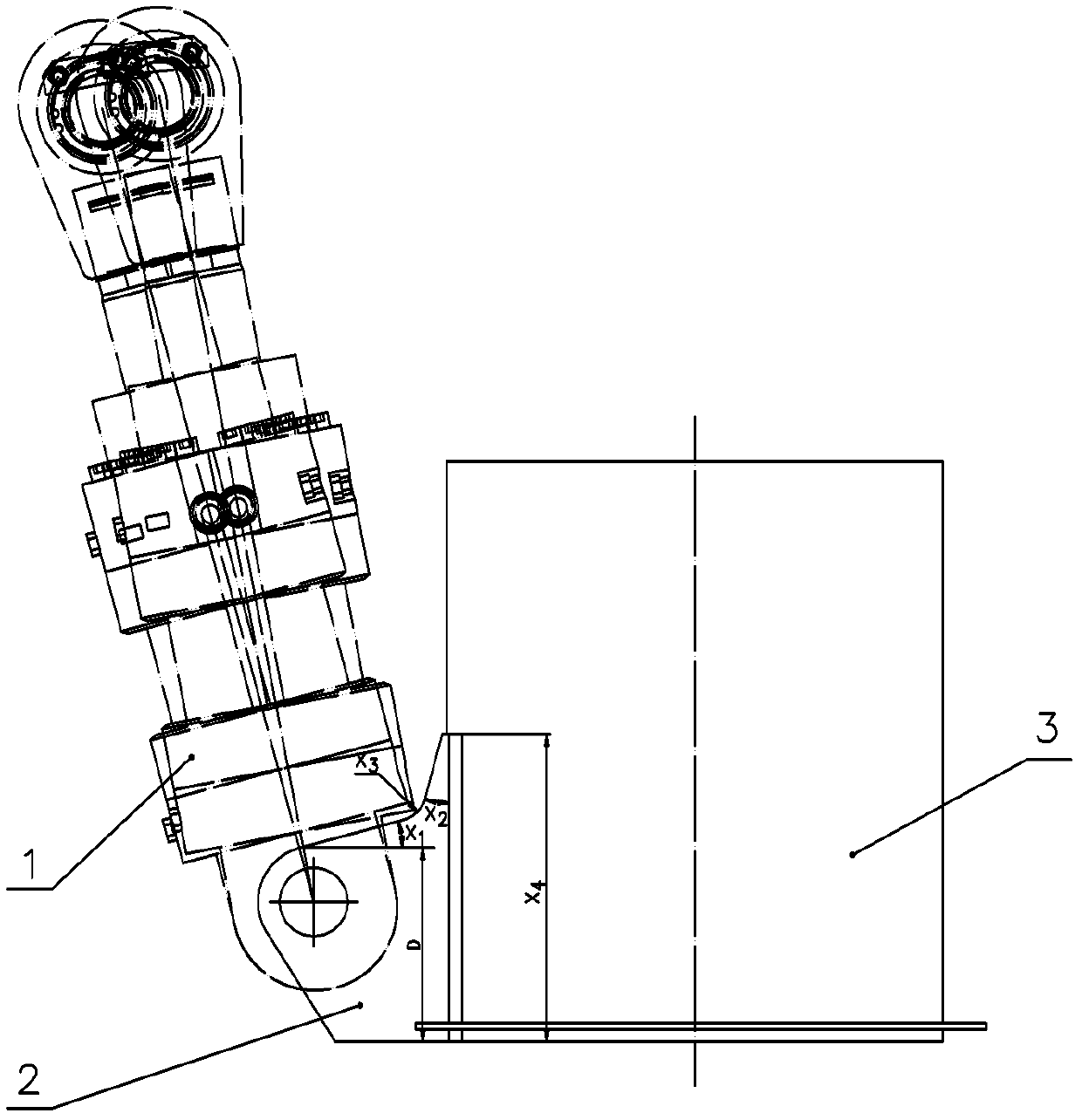

[0046] Specifically: the rotary cover removal machine moves the ditch cover to the working position or inspection position by pulling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com