Hollow composite insulator for 500-kV gas current transformer

A technology of current transformers and composite insulators, applied in the field of transformers, can solve the problems of reduced anti-pollution ability and inconvenient disassembly, and achieve the effects of easy disassembly and assembly, meeting the use requirements, and improving anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

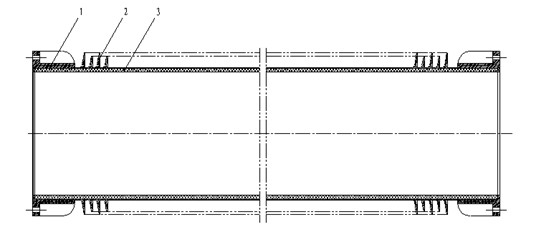

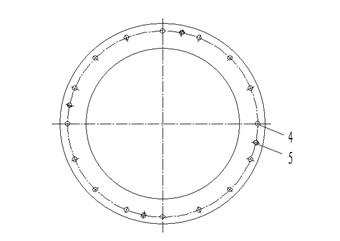

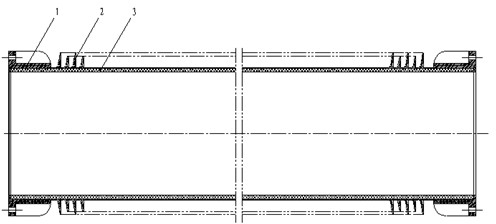

[0012] A hollow composite insulator for a 500kV gas current transformer, including an aluminum alloy flange 1, a silicone rubber shed 2 and an epoxy glass fiber tube 3. The epoxy glass fiber tube is a cylinder body wound by a wet method, and the silicone rubber shed is integrally cast on Outside the cylinder, the upper and lower ends of the cylinder are casted with aluminum alloy flanges; the aluminum alloy flange is provided with several process screw holes 5 and flange installation holes, and the process screw holes and flange installation holes 4 are on the same circumference. When disassembling, the hollow composite insulator is separated from the shell or the base with bolts through the process screw holes; the silicone rubber shed is umbrella-shaped, the creepage distance is not less than 20460mm, and the arc flash distance is the total hei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Creepage distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com