Microporous filter membrane and preparation method thereof

A technology of microporous membranes and organic membranes, applied in chemical instruments and methods, membranes, ultrafiltration, etc., can solve the problems of undisclosed microporous membranes, achieve high anti-pollution ability, high specific surface area, high surface opening The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention at first provides a kind of preparation method of microporous filter membrane, and this method comprises:

[0033] Step 1: Mix the polymer, thickener and solvent, stir at 50-100°C for 1-12 hours to dissolve, then add the porogen and stir, the temperature is preferably 80°C, and the stirring time is preferably 0.5-5h , cooled to room temperature, vacuum defoaming, the defoaming time is preferably 0.5-3h, and after standing, the casting solution of the polymer organic film is obtained; the standing time is preferably 1-24h;

[0034] The polymer is preferably selected from one or more of polysulfone, polyarylethersulfone, polyolefins, polyetherketone, polyimide sulfonated polysulfone, sulfonated polyethersulfone and polyetherimide kind;

[0035] The solvent is preferably selected from one or more of dimethylformamide, dimethylacetamide, N-methylpyrrolidone, caprolactam, and 1,4-dioxane;

[0036] The thickener is preferably selected from one or more ...

Embodiment 1

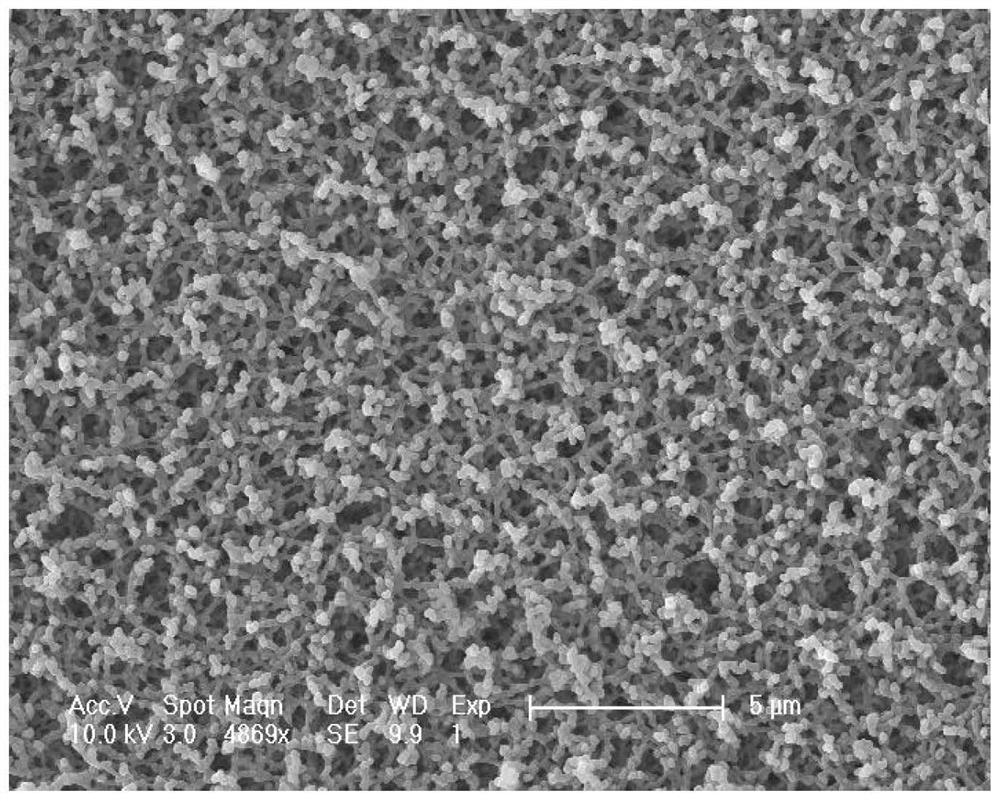

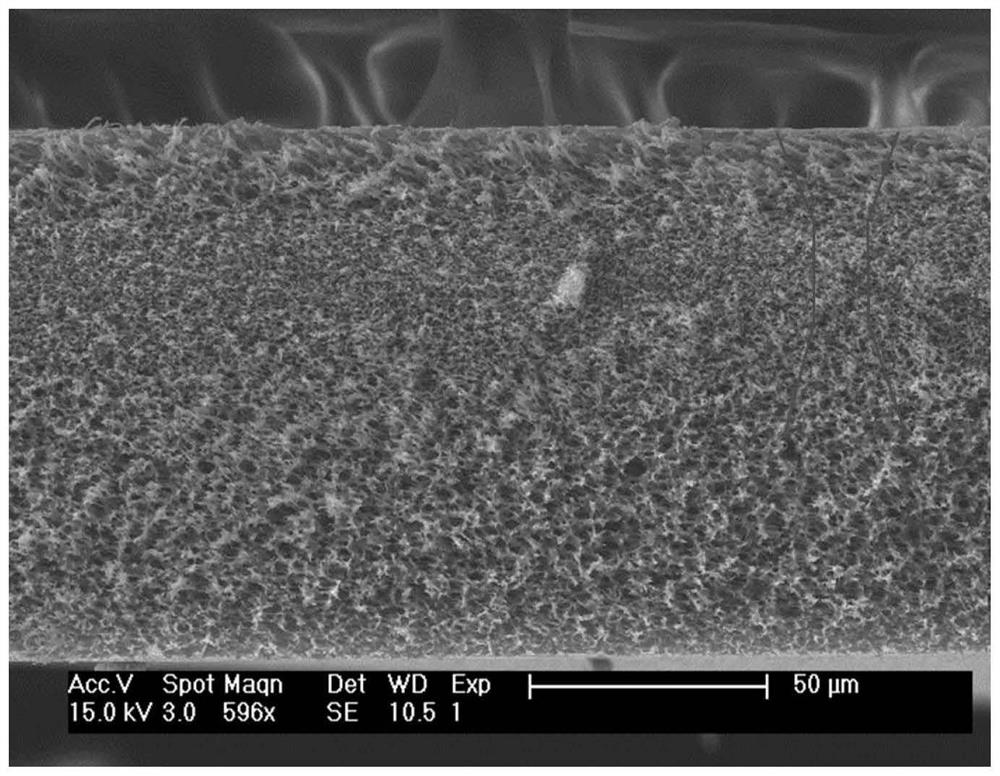

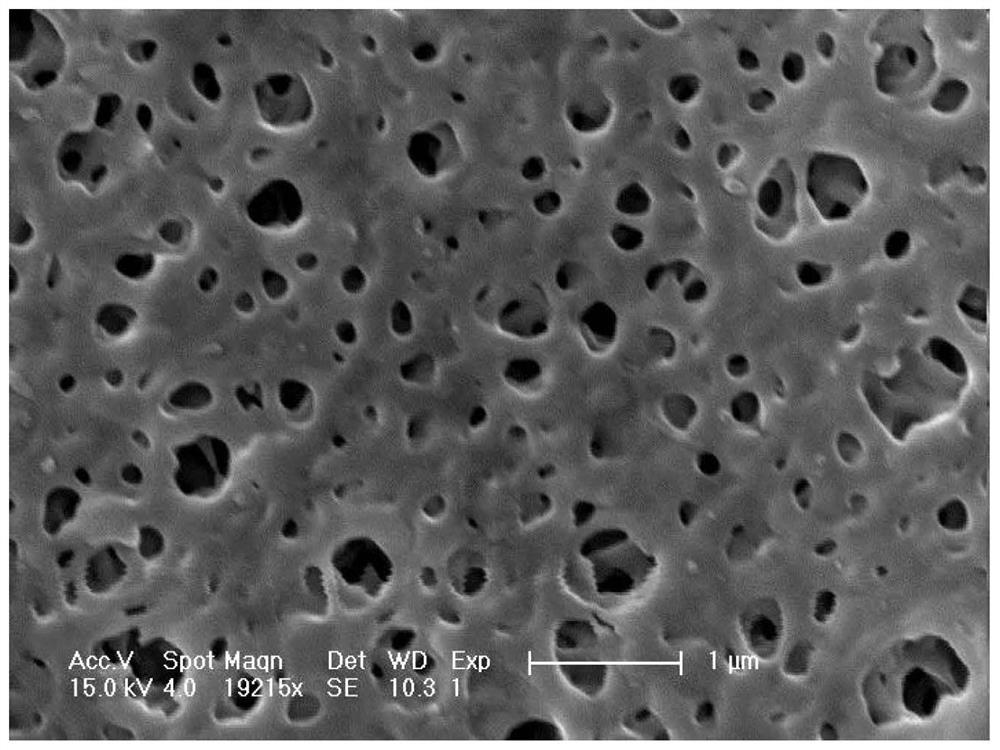

[0044] Example 1 Preparation of "hourglass" structure polyethersulfone microporous membrane with high specific surface area

[0045] According to the mass ratio of polyethersulfone resin (PES): polyvinylpyrrolidone: diethylene glycol: dimethylformamide = 15:10:45:30, add PES, polyvinylpyrrolidone, dimethylformamide to the melting pot Diethylene glycol was added into the porogen after stirring at 80°C for 4 hours, and the stirring was continued for 1 hour to prepare a stable and uniform viscous solution. The temperature was lowered to 25°C for 1 hour of defoaming, and then stood still for 8 hours to obtain a feed solution.

[0046] Scrape the feed liquid with a constant feed temperature of 25°C on a stainless steel strip or polypropylene resin with a 350 μm thick scraper, place it in humid air with a temperature of 25°C and a relative humidity of 60% for 10 seconds, and then place it at a temperature of 35 ℃, relative humidity of 70% in an air bath for 20s, then immersed in 50℃...

Embodiment 2

[0053] Prepare the solution according to the formula in Example 1, scrape the feed liquid with a constant feed liquid temperature of 25°C on the stainless steel strip or polypropylene resin with a 350 μm thickness scraper, and place it in a wet room with a temperature of 25°C and a relative humidity of 50%. In the air for 10s, then placed in an air bath with a temperature of 30°C and a relative humidity of 70% for 25s, then immersed in 50°C coagulation bath water for 8 minutes, and dried at 100°C, the measured bubble point pressure of water was 400Kpa-420KPa, and the pore size was 0.2μm, the measured pure water flux at 25°C is 28cc·min -1 cm -2 @70Kpa. The membrane has a structure with a high specific surface area and a separation layer between the upper and lower surfaces. Bovine serum albumin adsorption was 0.4% (bovine serum albumin solution 1.6 μg / 5ml water).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bubble point pressure | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com