Flat wire vertical winding machine

A vertical winding and flat wire technology, applied in the field of flat wire vertical winding machines, can solve the problems of a lot of wire consumption, complicated winding process, unstable current output of the welding machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

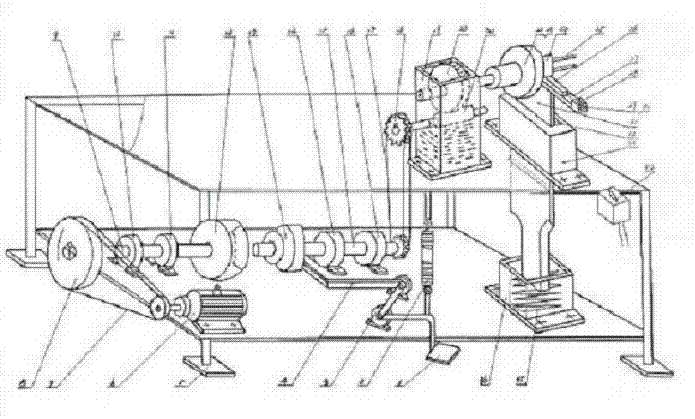

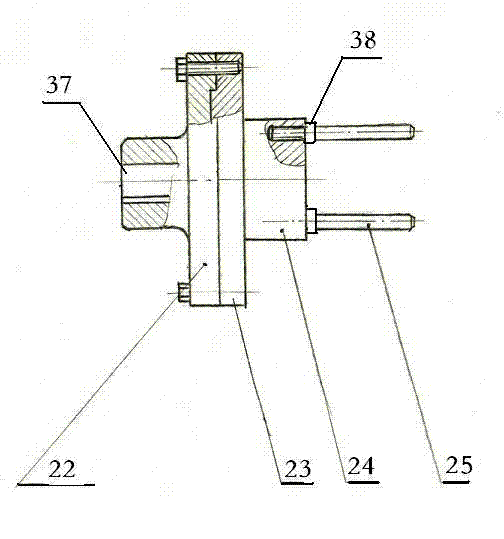

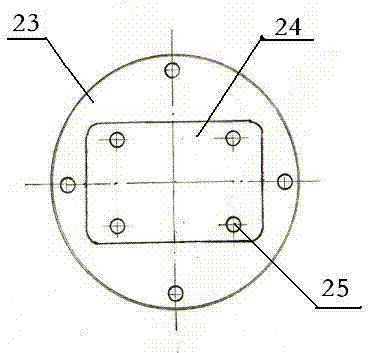

[0024] Below in conjunction with accompanying drawing, scheme is further described as an embodiment. refer to figure 1 , 2 , 3, 4, 5, 6, 7, 8:

[0025] The frame 5 of the flat wire vertical winding machine is made of upper and lower decks and four corners of the legs. Motor 6, belt 7, pulley 8, power transmission shaft 9, bearing housings 10, 11, and cone-disc clutch 12 are all installed on the front half of the lower platen, wherein the pulley at the motor shaft end and the pulley at the outer end of the cone-disk clutch 12 shaft form a deceleration fit form , to meet the welding machine coil winding speed requirements; two bearings 10 and 11 are fixed on the lower plate. The cone clutch 13 is fixed on the lower platform through the clutch bearing housings 14, 16, and the axis is on the same line as the aforementioned cone clutch; The big sprocket wheel of worm screw 21 outer ends cooperates unanimously, and two sprocket wheels form sprocket wheel group 18, and cover han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com