Bamboo bowl and production method thereof

A production method and technology for bamboo bowls, which are applied in the direction of plates, wood processing appliances, manufacturing tools, etc., can solve the problems of complex processing, low intensity and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

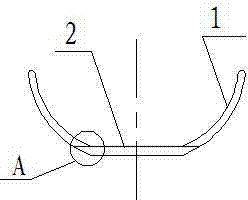

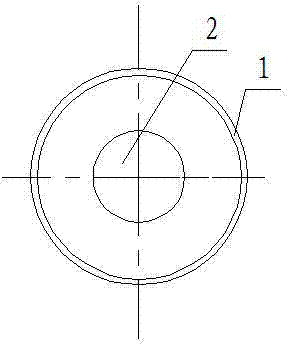

[0018] The present invention will be further described below with reference to the drawings and embodiments.

[0019] A method for producing bamboo bowls, which includes the following steps:

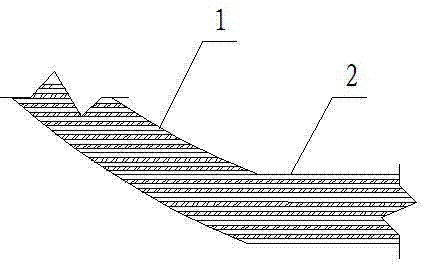

[0020] ⑴ Preparation of bamboo peeling veneer plywood;

[0021] Choose the straight bamboo that is free from mildew and decay, no moth-eaten fission, no one is injured, no obvious color difference, that is, no yin and yang, the brow diameter is more than 10 cm, and the straight bamboo material near the bamboo head is 130 cm to 430 cm.

[0022] Cut the selected bamboo into 340mm-350mm (340mm in this embodiment) long bamboo tube. When cutting, each section of the bamboo tube retains at least one bamboo section, so as to reduce the veneer longitudinal cracking after the veneer is peeled.

[0023] Steaming, rotary cutting. Put the bamboo tube after opening the septum into an iron hanging cage and put it into a steaming kettle to immerse in water and heat to soften it. After heating the water to boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com