Aerogenerator cable mandrel

A technology for wind turbines and cable cores, which is applied to wind turbine components, wind engines, wind power generation, etc., and can solve problems such as the influence of shaft rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

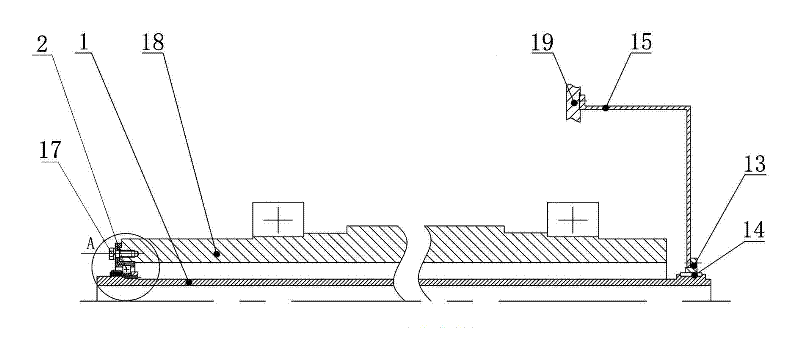

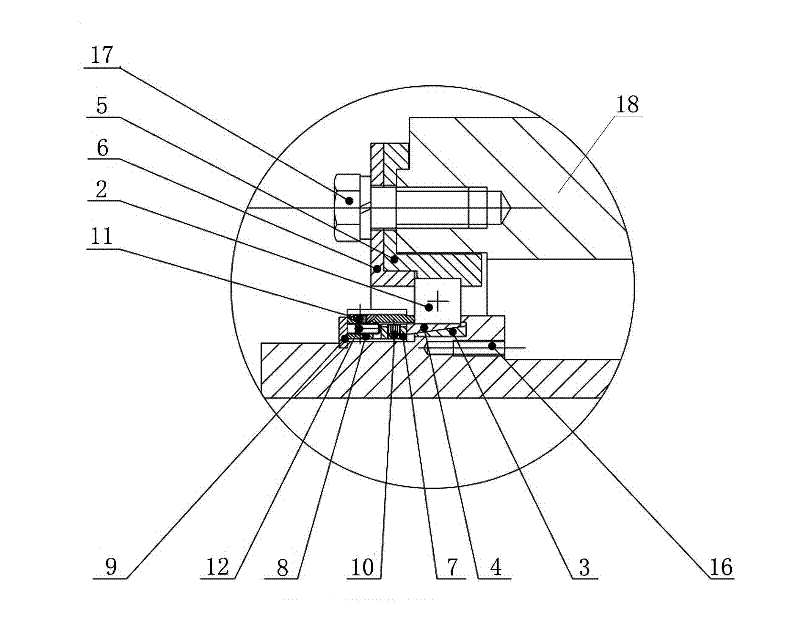

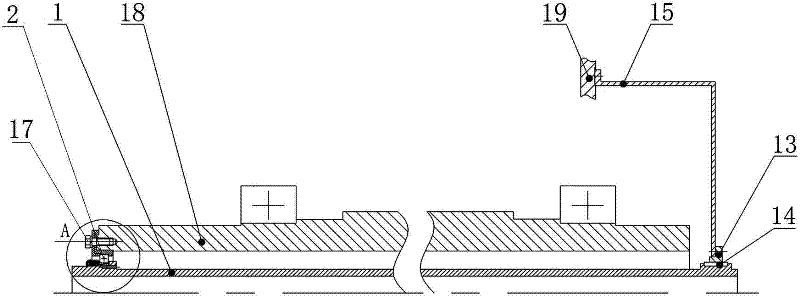

[0011] The wind power generator cable mandrel includes a mandrel 1; a sealed bearing 2 is installed at the front end of the mandrel 1; a tapered expansion sleeve is provided between the inner ring of the sealed bearing 2 and the outer surface of the mandrel 1, and the tapered expansion sleeve includes an inner The collar 3 and the outer collar 4, the inner collar 3 is socketed on the outer surface of the mandrel 1, the outer collar 4 is socketed between the outer surface of the inner collar 3 and the inner ring of the sealed bearing 2; the outer ring of the sealed bearing 2 is socketed There is a bearing seat 5, and the outer end surface of the bearing seat 5 is equipped with an annular gland 6; the front end of the mandrel 1 is respectively sleeved with a small nut 7, a large nut 8, and a spring retaining ring 9 for the shaft; the inner end surface of the small nut 7 is connected to the tapered The outer end surface of the expansion sleeve is in contact, the inner end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com