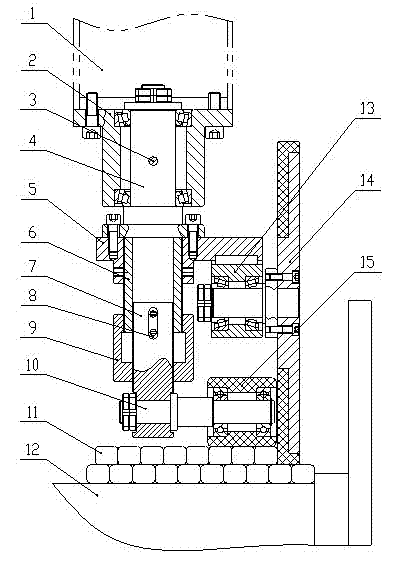

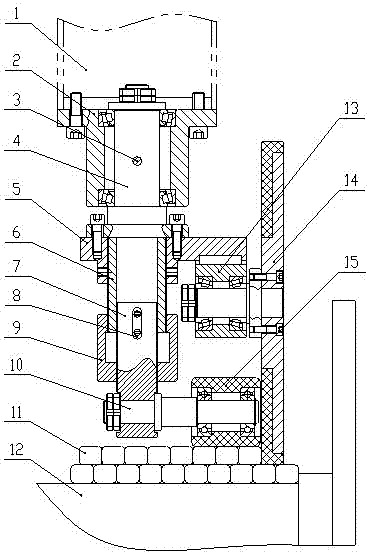

Coil compacting mechanism used during transformer coil winding

A technology of transformer coil and compression mechanism, applied in coil manufacturing and other directions, can solve the problems of inconvenient height adjustment, poor cable linearity, easy to slip and damage the lower cable, etc., to improve the compression effect, good linearity, and easy to determine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

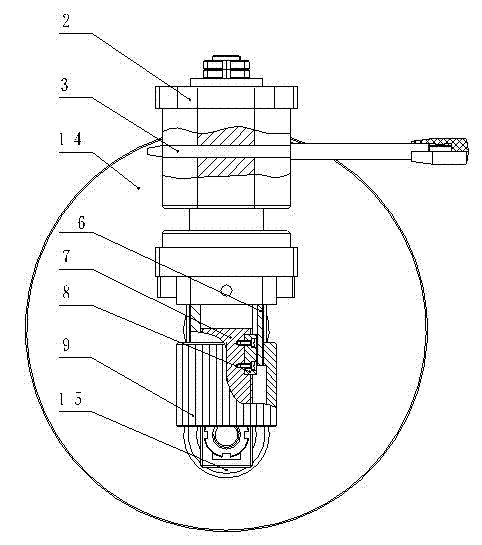

[0022] Embodiment 2: On the basis of the above-mentioned embodiment, the material of the pressing disc 14 can be carbon steel, and heat treatment after finish machining ensures its rigidity, and the right end surface and side of the pressing disc 14 are coated with wear-resistant nylon or Polyurethane material, to avoid direct contact between the metal surface and the cable.

[0023] Depend on figure 2 It is not difficult to see that the inner screw 7 and the hollow stud 6 cooperate and are guided by the guide wire key 8, and the relative sliding up and down can be realized by rotating the left and right threaded sleeve 9, which is exactly the height adjustment of the pressing device provided by this embodiment. where.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com