Electrically driven vehicle

A technology for electric vehicles and electric motors, which is applied to electric vehicles, electric scooters, motor vehicles, etc., can solve the problems of generating rotational resistance, difficult to start, and the installation space cannot use electric motors, and achieves the effect of a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

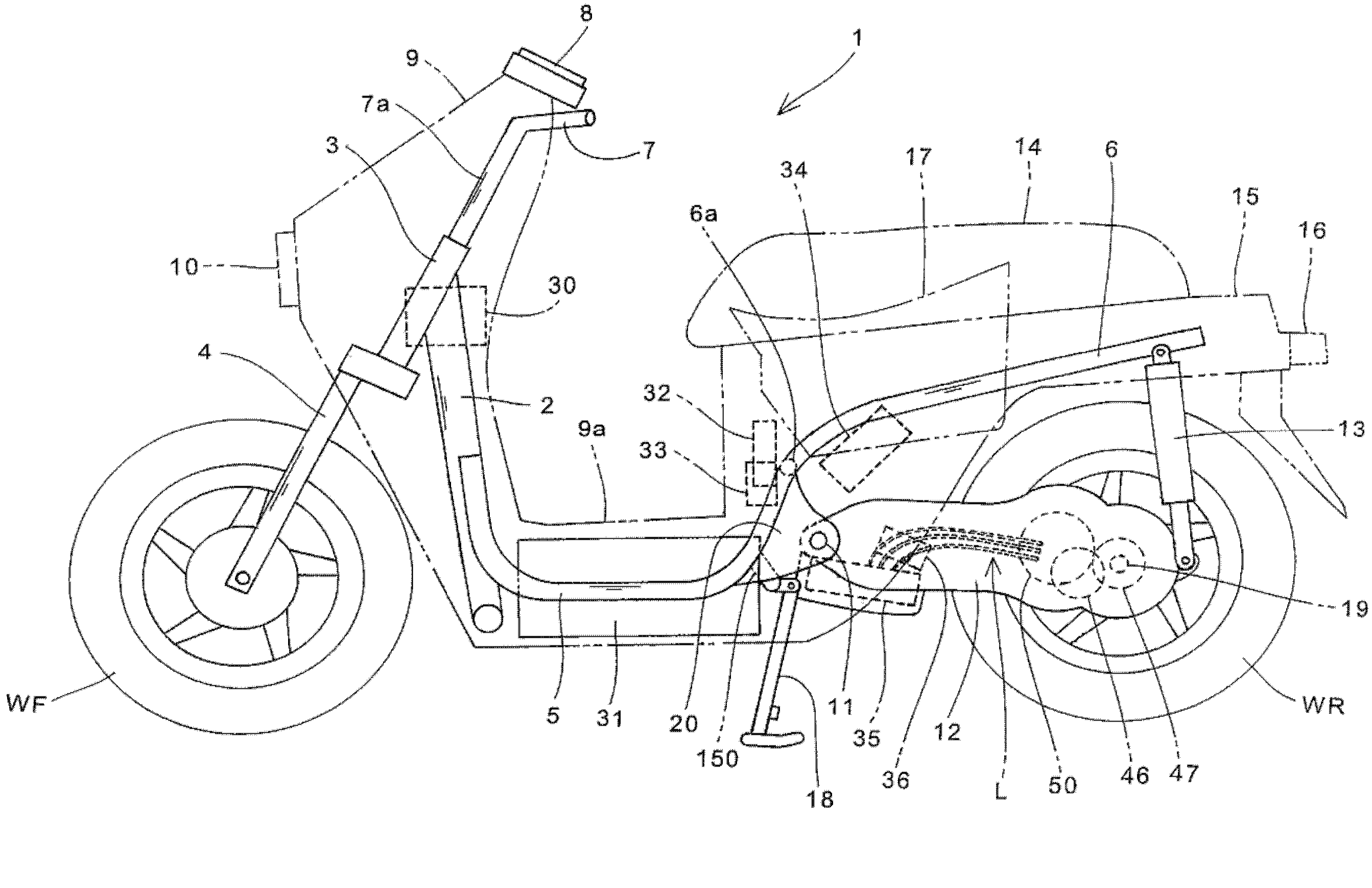

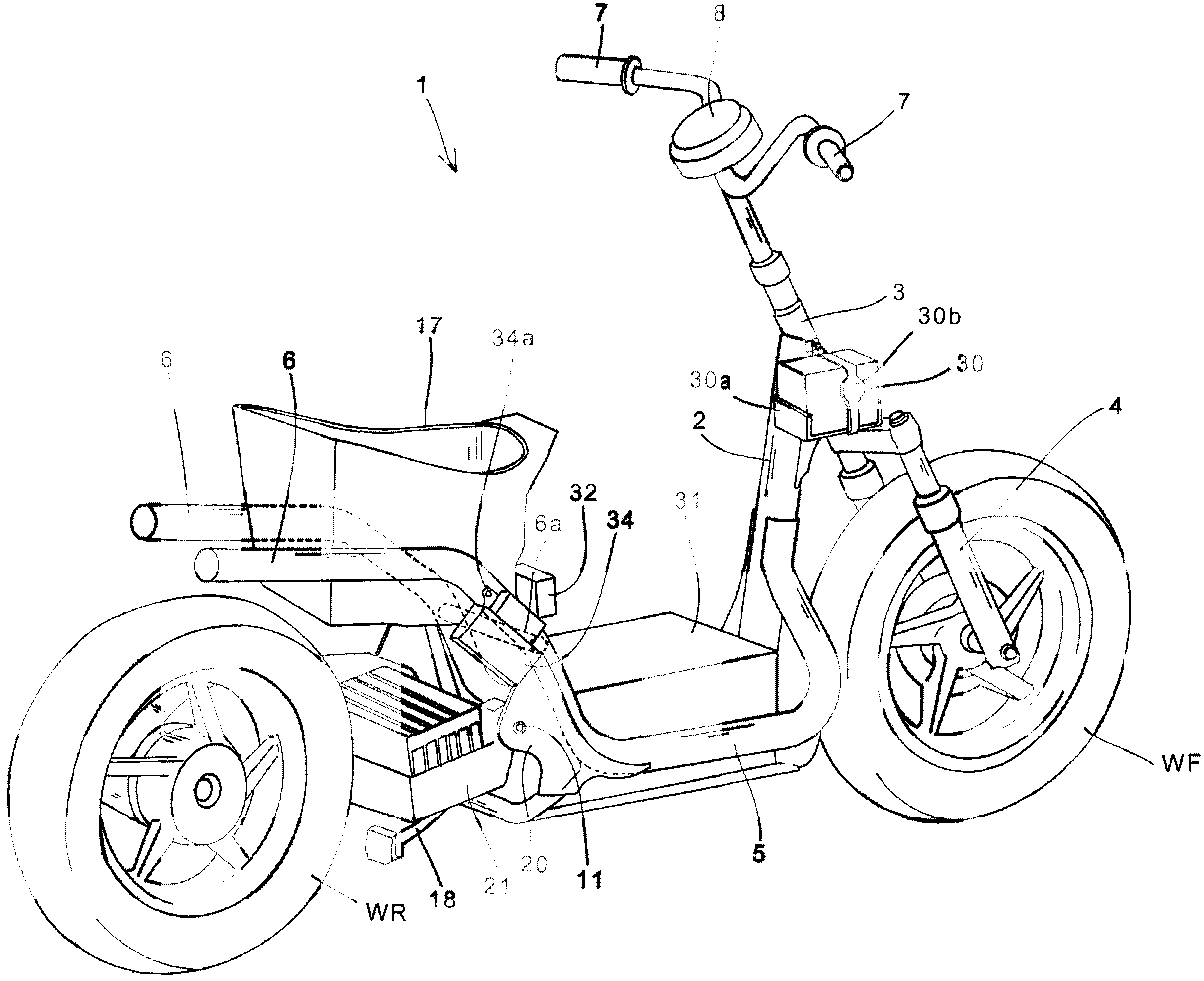

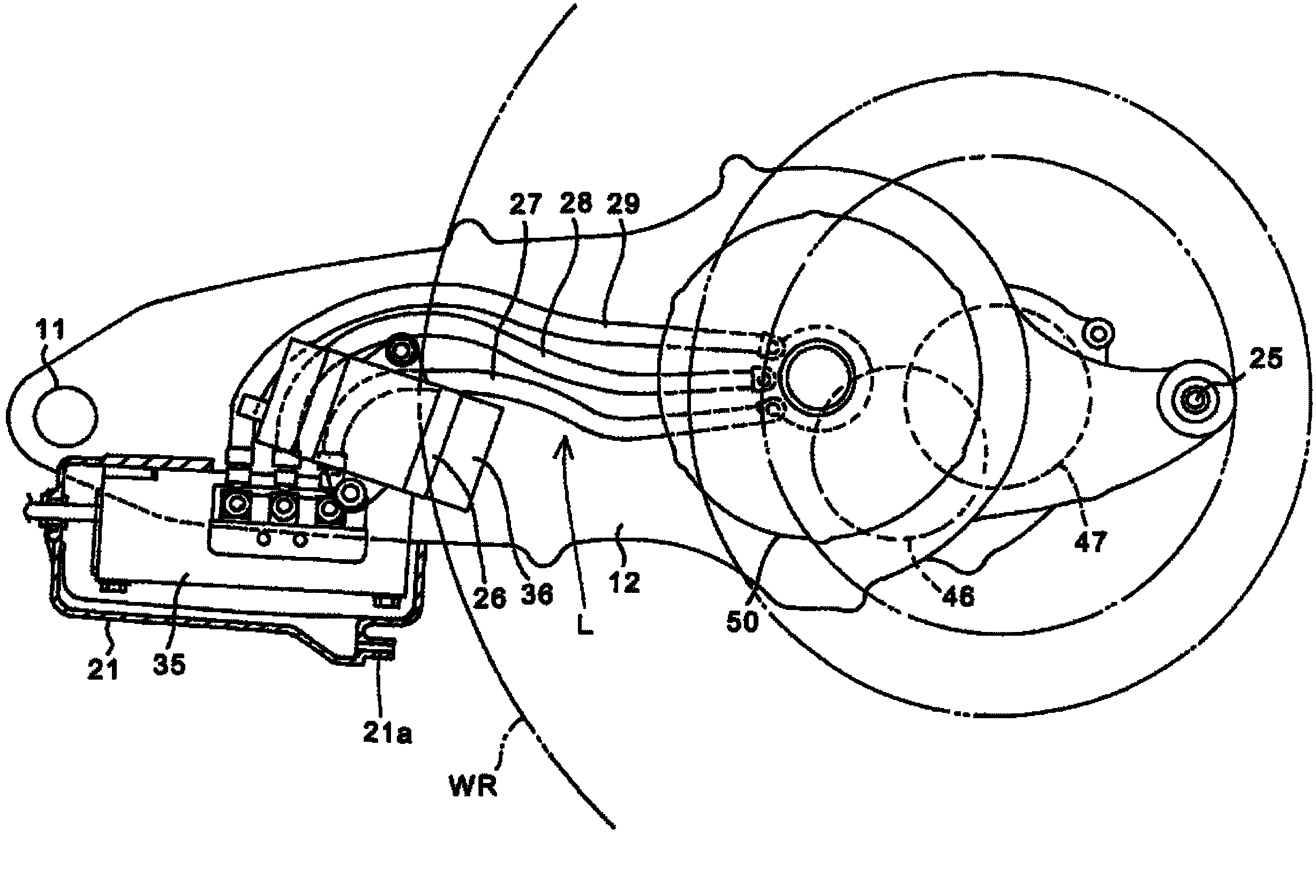

[0036] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a side view of the electric vehicle 1 according to one embodiment of the present invention. in addition, figure 2 It is a rear perspective view of the electric vehicle 1 with exterior parts removed. The electric vehicle 1 is a scooter-type motorcycle with a low floor, and the rear wheels WR are driven by the rotational driving force of the electric motor 50 built in the swing arm 12 . In addition, the high-voltage battery 31 that supplies electric power to the electric motor 50 is charged by connecting an external power supply to a charging port (not shown) provided in the vehicle body.

[0037] A head pipe 3 that rotatably pivotally supports a steering rod 7 a is coupled to a front side end portion of the main frame 2 . A steering handle 7 is attached to the upper portion of the steering rod 7a, and a pair of left and right front fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com