Liquid raw material vaporizer

A technology for liquid raw materials and gasification devices, which is applied in gas generating devices, gaseous chemical plating, electrical components, etc., can solve the problems of reduced gasification efficiency, larger bubbles, and inability to obtain bubble stirring effects, and achieves uniform temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

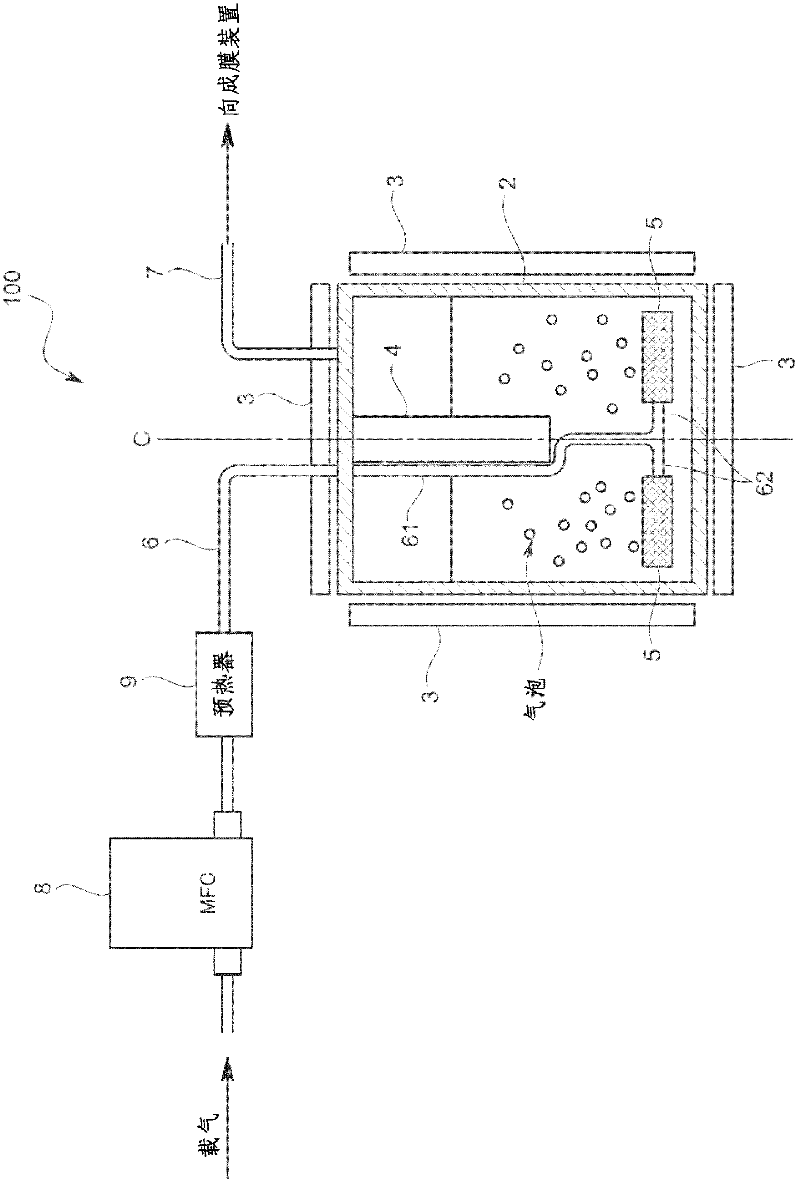

[0025] One embodiment of the liquid raw material gasification device of the present invention will be described below with reference to the drawings.

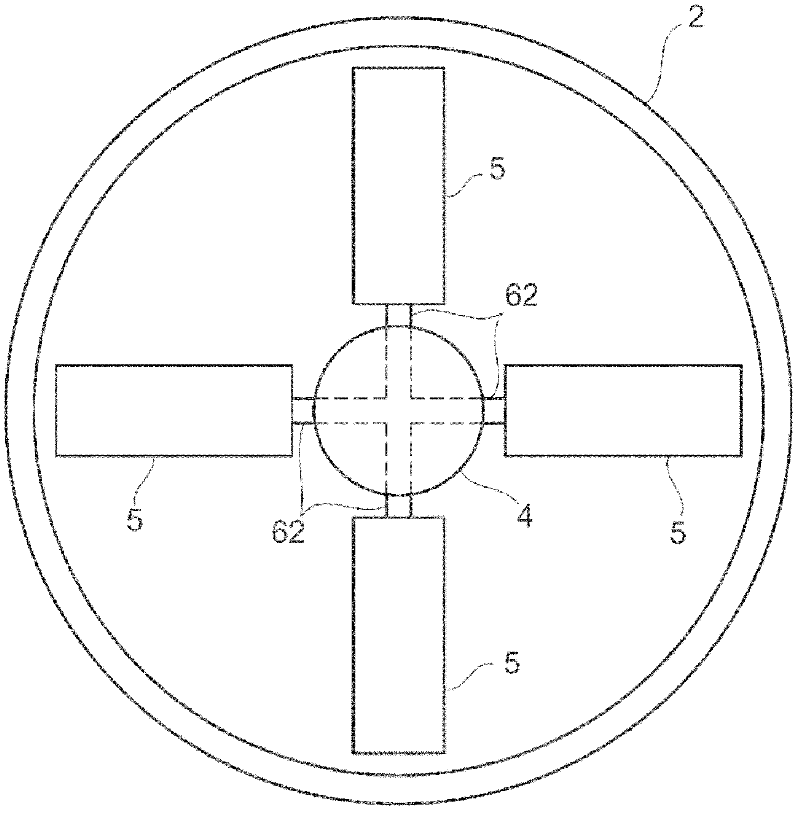

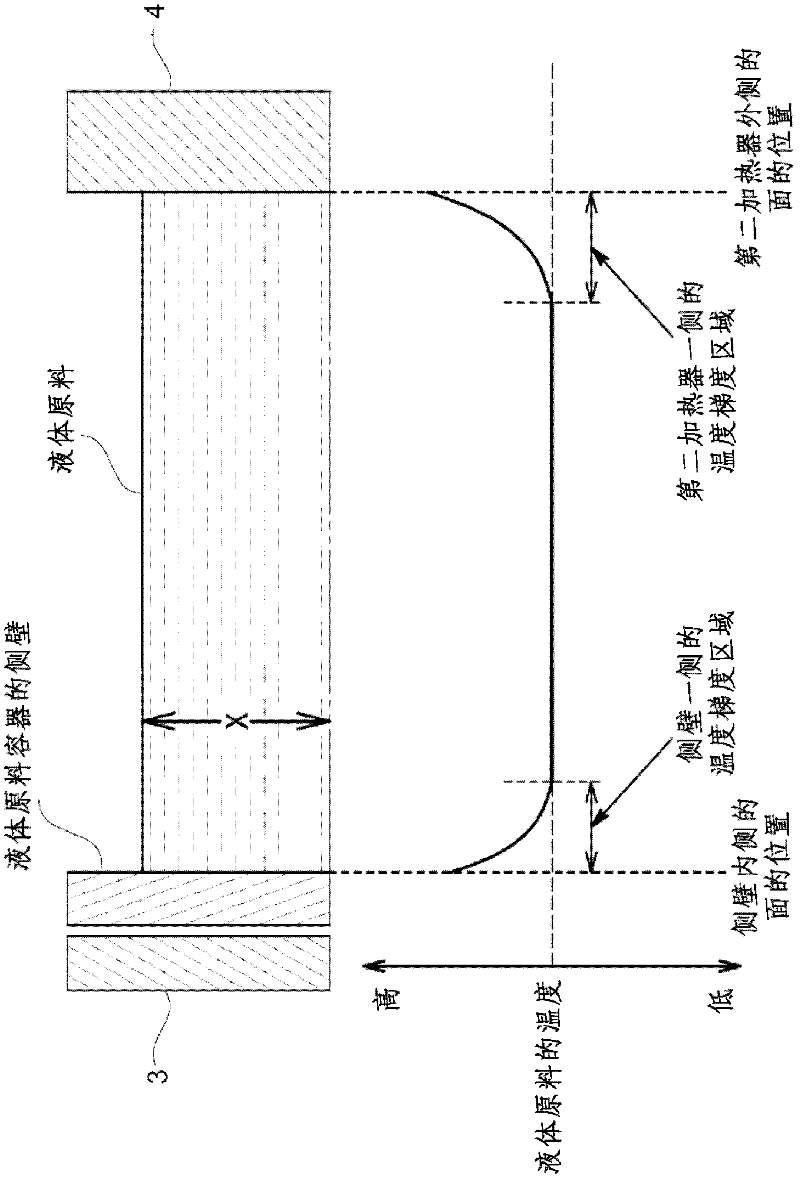

[0026] The liquid raw material gasification device 100 of this embodiment vaporizes the liquid raw material as a film-forming raw material by a bubbling method, and supplies it to a film-forming device using a CVD method, such as figure 1 As shown, the liquid raw material gasification device 100 includes: a liquid raw material container 2 for storing liquid raw materials such as tetraethoxysilane (TEOS); The upper part is used to heat the stored liquid raw material to a specified temperature; the second heater 4 is arranged in the inner central part of the liquid raw material container 2, and is used to heat the stored liquid raw material to a specified temperature; a plurality of bubble generators 5, immersed in the stored liquid raw material, and set between the second heater 4 and the side wall, used to spray carrier gas int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com