Preparation technology of carbon-yttrium modified titanium dioxide photocatalyst

A titanium dioxide and photocatalyst technology is applied in the field of preparation technology of carbon yttrium modified titanium dioxide photocatalyst to achieve the effects of improving photocatalytic performance, increasing specific surface area and inhibiting grain size growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

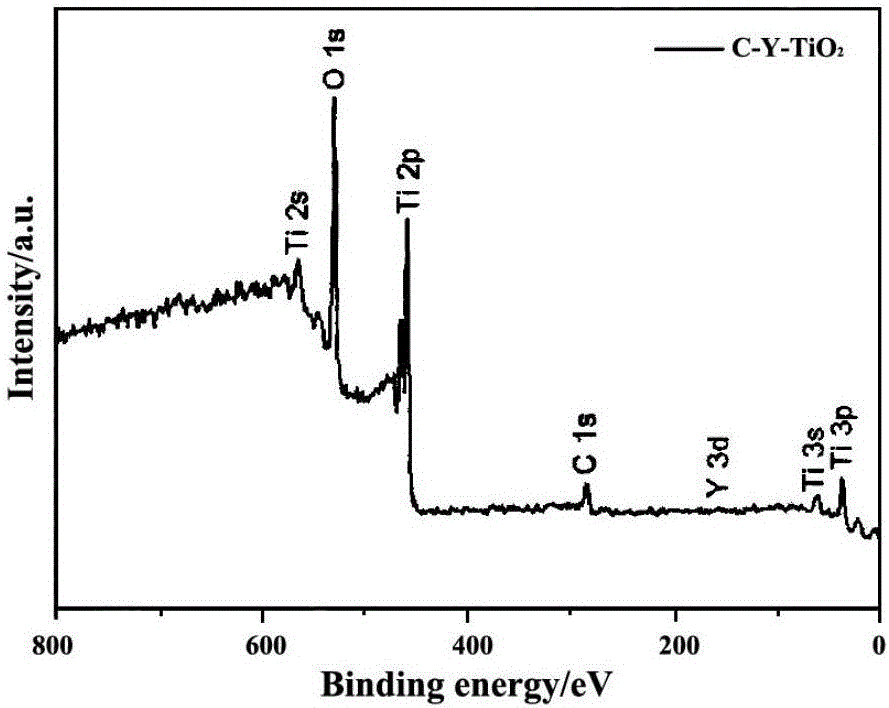

Image

Examples

Embodiment 1

[0025] The preparation technology of carbon yttrium modified titanium dioxide photocatalyst, concrete steps comprise:

[0026] a. Prepare solution Ⅰ, prepare 180ml ethanol CH 3 CH 2 OH, 60ml tetrabutyl titanate C 16 h 36 o 4 Ti, 10ml glacial acetic acid C 2 h 4 o 2 , 10ml deionized water, mixed for later use;

[0027] b. Prepare solution II and prepare ethanol CH 3 CH 2 OH, 1.4g yttrium nitrate Y (NO 3 )·6H 2 O, deionized water, the mass ratio is CH 3 CH 2 OH: Y (NO 3 )·6H 2 O: H 2 O=8:1:1, use dilute nitric acid with a concentration of 2mol / L to control the pH value to 2-3, mix and set aside;

[0028] c. To prepare a mixed solution, put solution I in a stirrer, slowly add solution II dropwise under vigorous stirring at 1250-1300r / min, and then drop D-glucose C with a concentration of 2mol / L 6 h 12 o 6 ·H 2 O, the dosage is 4.5ml;

[0029] d. Stir the mixed solution obtained in step c continuously under the condition of 1250-1300r / min until it becomes a gel,...

Embodiment 2

[0033] The preparation technology of carbon yttrium modified titanium dioxide photocatalyst, concrete steps comprise:

[0034] a. Prepare solution Ⅰ, prepare 180ml ethanol CH 3 CH 2 OH, 60ml tetrabutyl titanate C 16 h 36 o 4 Ti, 10ml glacial acetic acid C 2 h 4 o 2 , 10ml deionized water, mixed for later use;

[0035] b. Prepare solution II and prepare ethanol CH 3 CH 2 OH, 2.5g yttrium nitrate Y (NO 3 )·6H 2 O, deionized water, the mass ratio is CH 3 CH 2 OH: Y (NO 3 )·6H 2 O: H 2 O=8:1:1, use dilute nitric acid with a concentration of 2mol / L to control the pH value to 2-3, mix and set aside;

[0036] c. To prepare a mixed solution, put solution I in a stirrer, slowly add solution II dropwise under vigorous stirring at 1250-1300r / min, and then drop D-glucose C with a concentration of 2mol / L 6 h 12 o 6 ·H 2 O, the dosage is 150ml;

[0037] d. Stir the mixed solution obtained in step c continuously under the condition of 1250-1300r / min until it becomes a ge...

Embodiment 3

[0042] A preparation process of carbon yttrium modified titanium dioxide photocatalyst, comprising the process steps of doping C and Y in titanium dioxide, the process of doping elements in titanium dioxide includes the steps of doping yttrium and doping carbon, and the specific steps include:

[0043] a. Prepare solution Ⅰ, prepare 22ml ethanol CH 3 CH 2 OH, 8ml tetrabutyl titanate C 16 h 36 o 4 Ti, 1.5ml glacial acetic acid C 2 h 4 o 2 , 1.5ml deionized water, mixed for later use;

[0044] b. Prepare solution II and prepare ethanol CH 3 CH 2 OH, 1.44g yttrium nitrate Y (NO 3 )·6H 2 O, deionized water, the mass ratio is CH 3 CH 2 OH: Y (NO 3 )·6H 2 O: H 2 O=10:3:3, use dilute nitric acid with a concentration of 2mol / L to control the pH value to 2-3, mix and set aside;

[0045] c. To prepare a mixed solution, put solution I in a stirrer, slowly add solution II dropwise under vigorous stirring at 1250-1300r / min, and then drop D-glucose C with a concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com