Carbon nitride based material for photocatalytic water total decomposition as well as preparation and application thereof

A carbon nitride-based, photocatalytic technology, used in chemical instruments and methods, physical/chemical process catalysts, electrolysis processes, etc., can solve problems such as deactivation, and achieve the effects of inhibiting separation, preventing rapid recombination, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

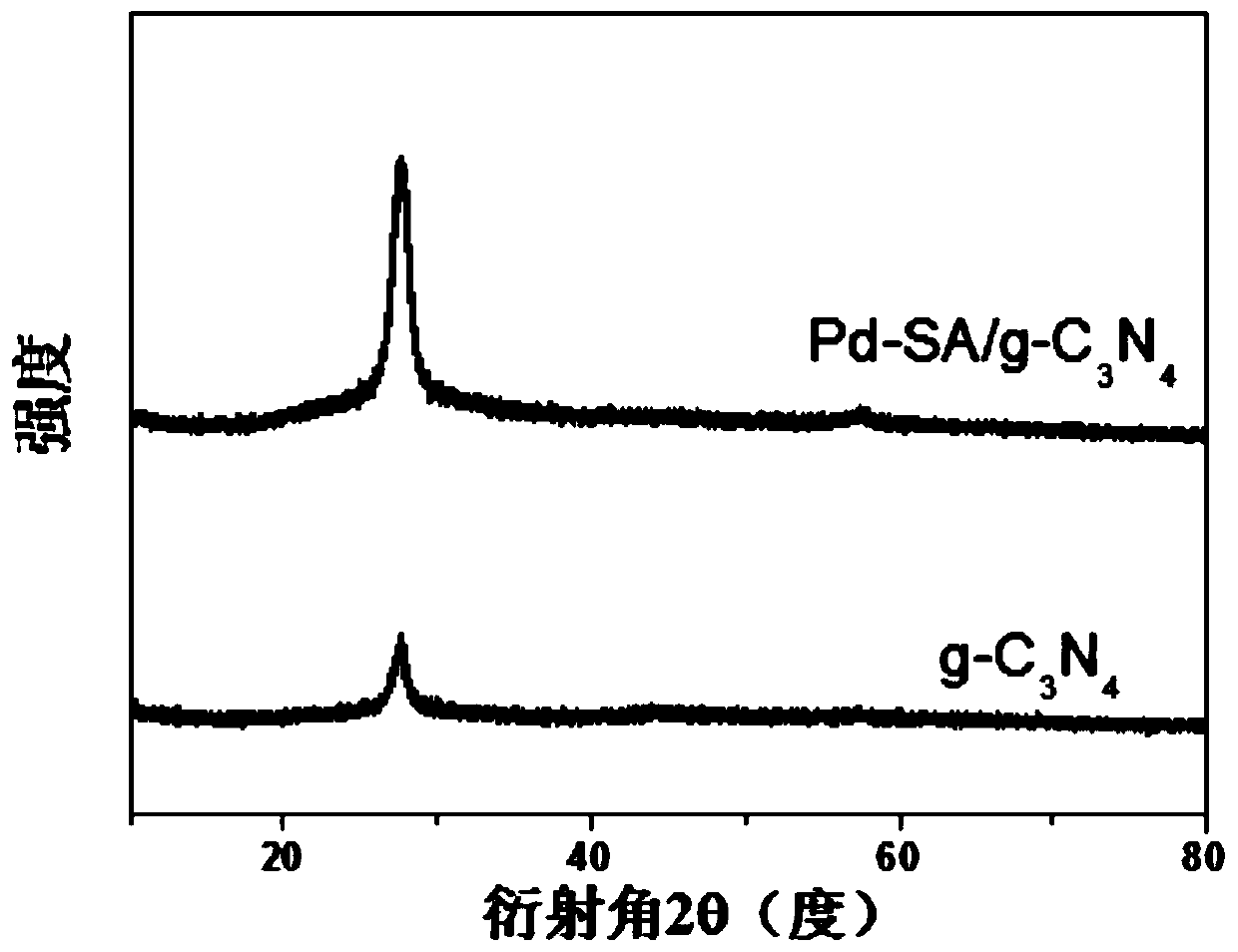

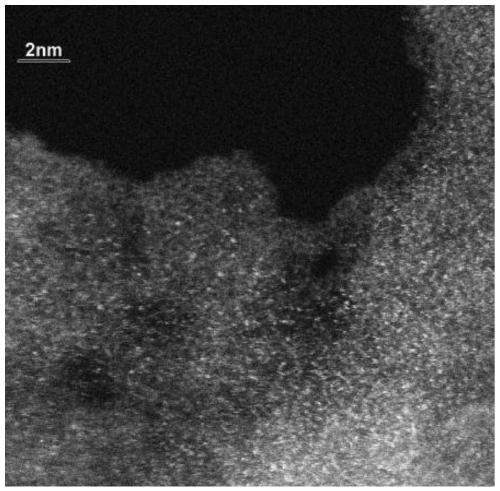

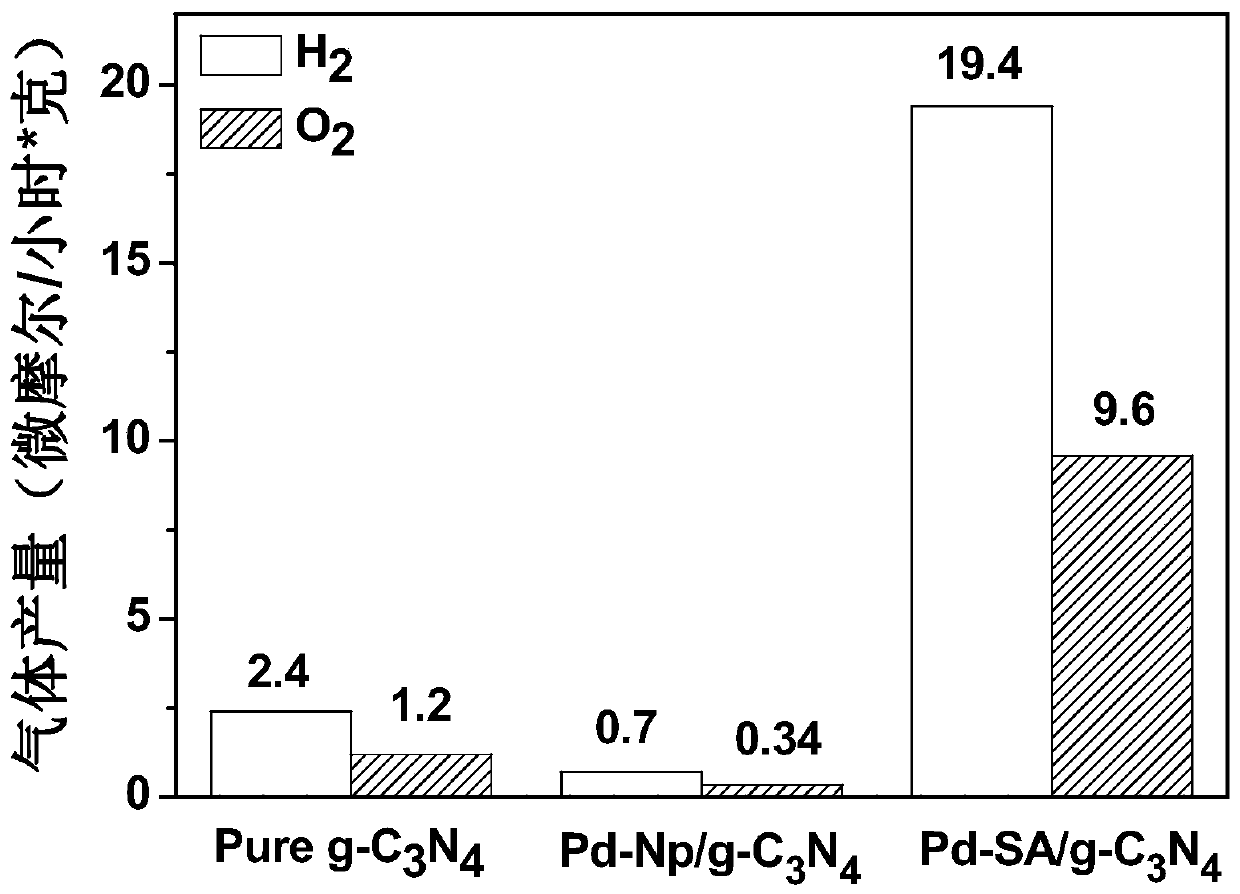

[0035] A carbon nitride-based material for photocatalytic total water splitting, comprising a carbon nitride carrier, the carbon nitride carrier is loaded with monoatomic palladium, and the loading amount of the monoatomic palladium is 0.0925wt.%.

[0036] Utilize impregnation-high-temperature anchoring method to prepare described carbon nitride-based materials for photocatalytic total water splitting, that is, support monoatomic palladium on the surface of carbon nitride and between layers, the quality of palladium in the palladium source of this embodiment is comparable to that of graphite The mass ratio of phase carbon nitride is 0.0016:1. The specific steps are:

[0037] Weigh 10g of melamine and place it in a crucible, then place the crucible in a muffle furnace, raise the temperature to 500°C at a rate of 2°C / min, then keep it for calcination for 2 hours, then raise it to 520°C for calcination at the same rate After 2 hours, after naturally cooling to room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com