Kitchen utensil for stewing foods

A technology for cooking and cabinets, which is applied in the directions of food preparation, food science, and application, can solve the problems of difficulty in improving, metal fatigue, and cleaning difficulties, and achieves the effects of improving fuel utilization rate, good heat preservation function, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

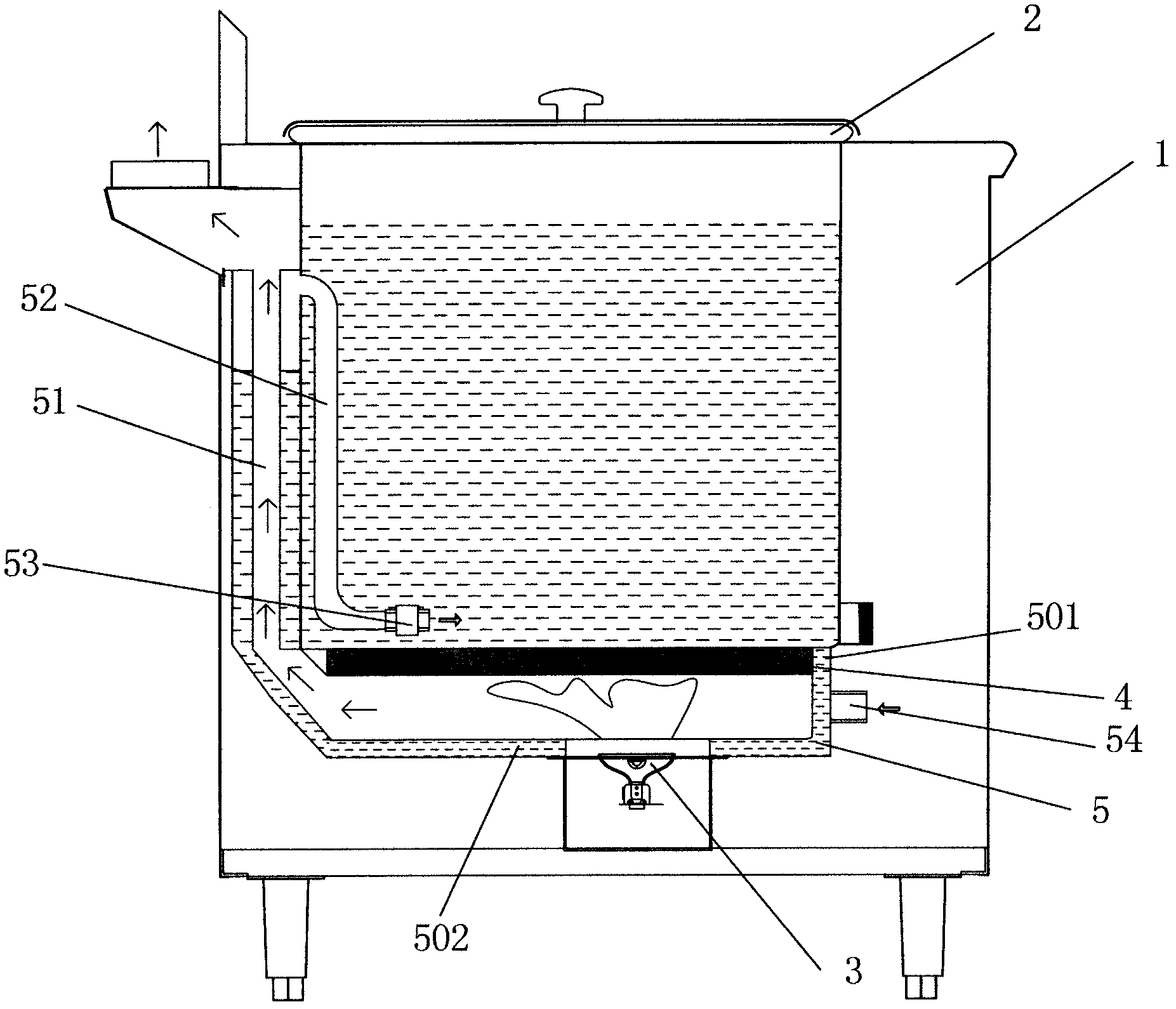

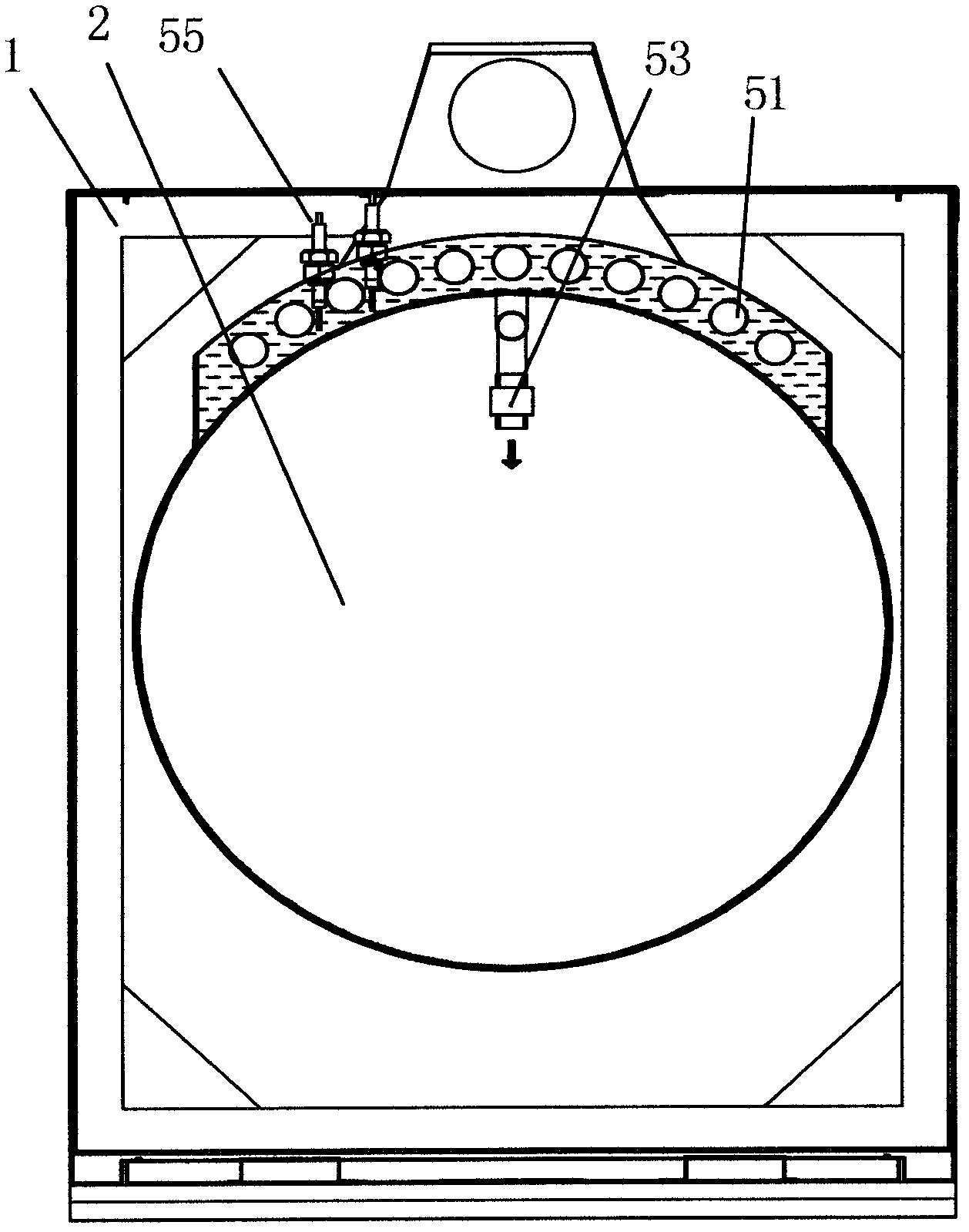

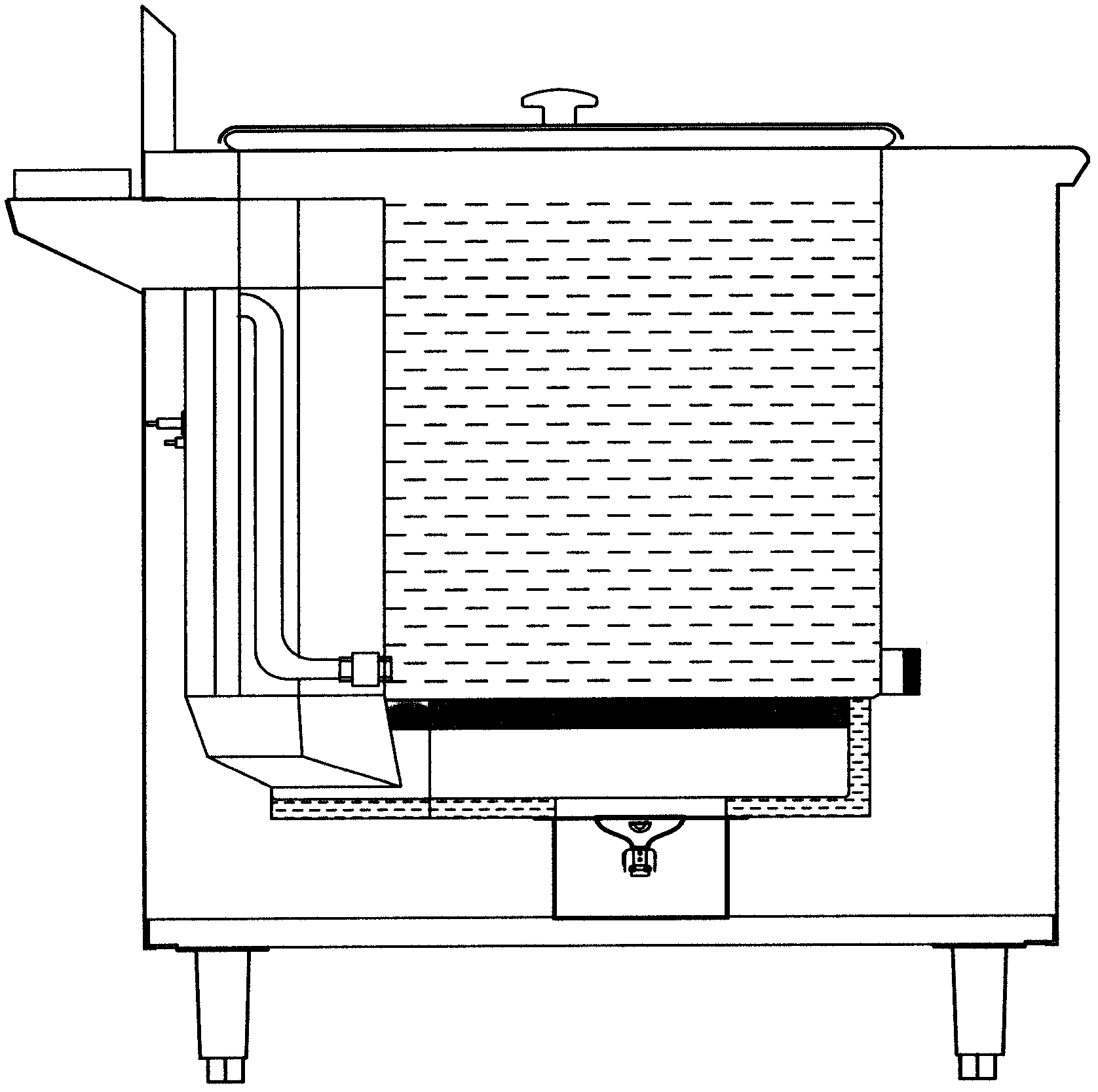

[0014] Such as Figure 1 to Figure 3 As shown, a kind of cabinet equipment for cooking food includes an outer bracket 1, an inner tank 2 and a burner 3, the inner tank 2 is arranged inside the outer bracket 1, and the burner 3 is arranged inside The bottom of the liner 2 is characterized in that a crucible layer 4 is arranged between the inner liner 2 and the burner 3, and an annular water jacket 5 is arranged on the periphery of the burning area of the burner 3, and the annular water jacket 5. A wet back heating area is formed on the wall of the pot. There are multiple wet back fire pipes 51 connected to the wet back heating area. The middle of the wet back fire pipes is the flue of the burner. The end of the wet backfire pipe 51 is connected with a steam delivery pipe 52 , and the end of the steam delivery pipe 52 is provided with a one-way valve 53 . The heater is surrounded by the annular water jacket 5 in all directions, and the heat generated by gas combustion is full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com