Pushing device for inside and outside direction and rotary direction of tool in gear processor

A technology of rotating direction and pushing device, applied in the field of machinery, can solve the problems of poor mechanical work stability, difficult manufacturing, insufficient rigidity, etc., and achieve the effects of safe and reliable work, improved machining accuracy, and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

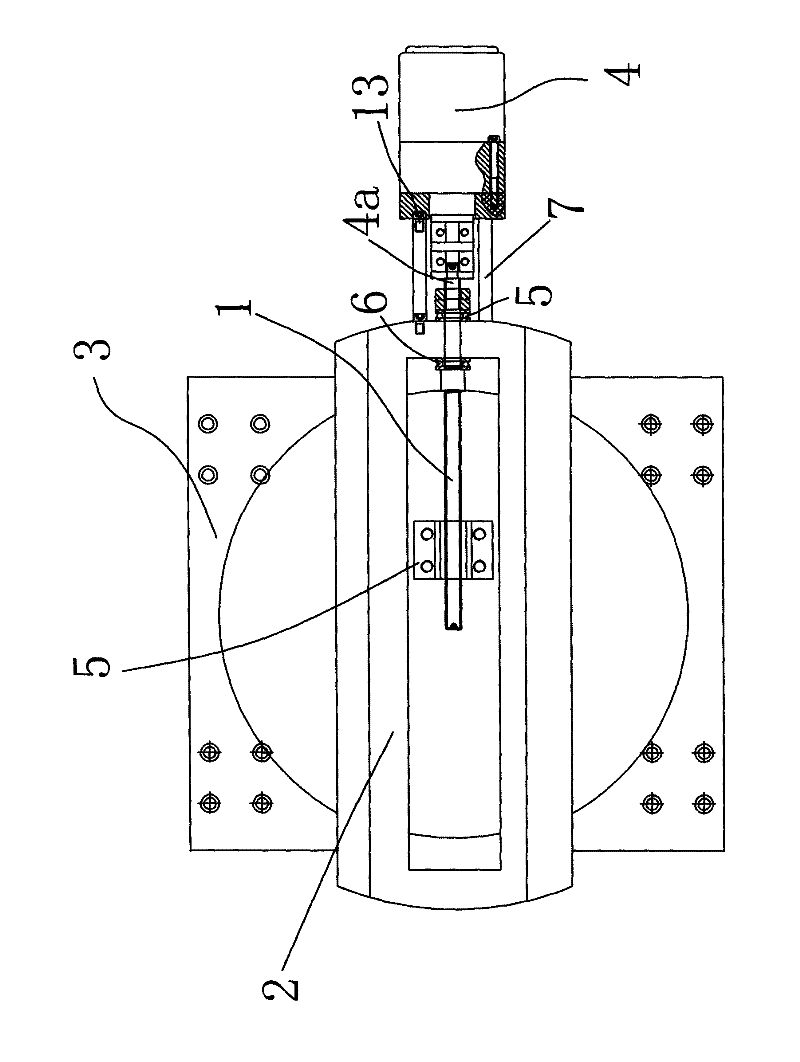

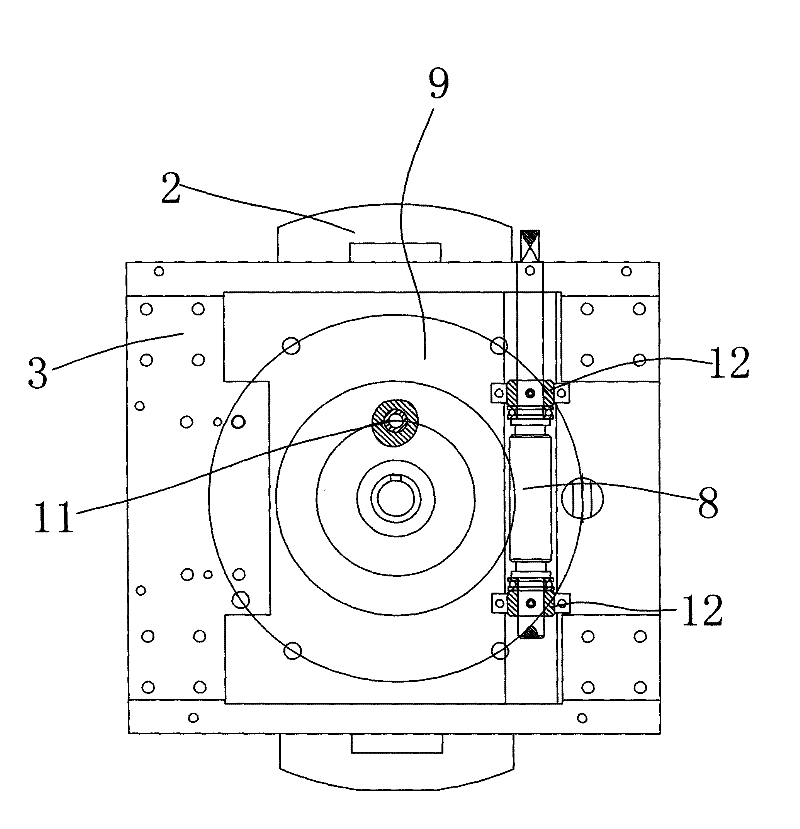

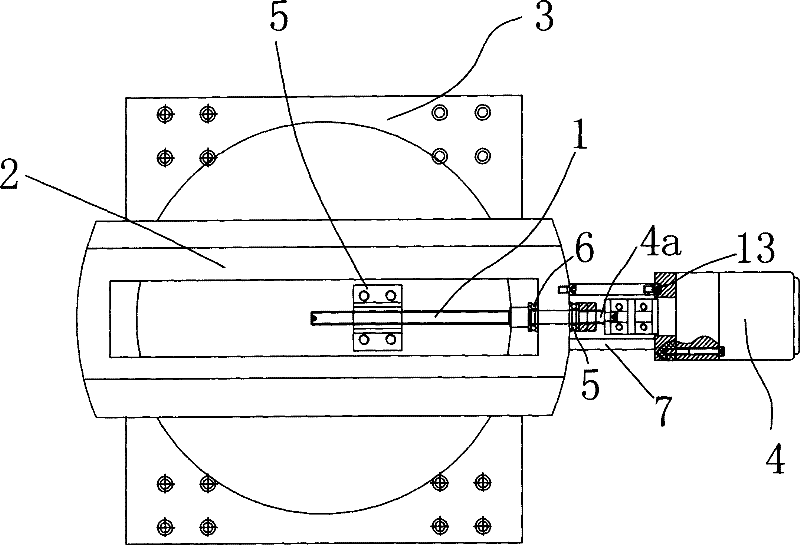

[0012] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0013] In the figure, screw mandrel 1; tool seat 2; slide plate 3; motor 4; output shaft 4a; nut seat 5; plane bearing 6; connecting plate 7; connecting sleeve 8; worm wheel 9; worm 10; washer 11; steel sleeve 12; Hexagon socket head cap screw 13.

[0014] like figure 1 As shown, the driving device in the gear processing machine in the internal and external directions and the rotating direction of the tool mainly drives the tool to move in the internal and external directions and the rotating direction, including the screw rod 1, the tool seat 2, the slide plate 3, the motor 4, the nut seat 5, and the slide plate 3 and the nut seat 5 are fixedly connected with the hexagon socket head screw 13, the knife seat 2 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com