Rubber bellows model lamination manufacturing device and its manufacturing method

A manufacturing method and bellows technology, applied in the field of equipment for producing rubber bellows, can solve problems such as the need to use solvents, high precision requirements for model manufacturing, and inconvenient repairs, so as to reduce unstable flow, random changes, and molds The effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

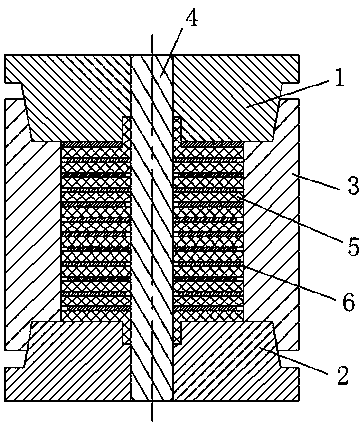

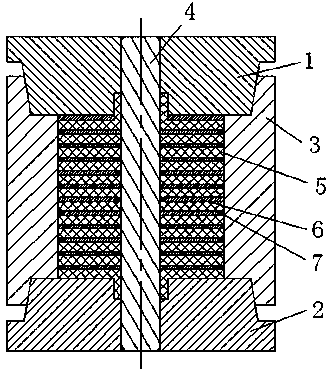

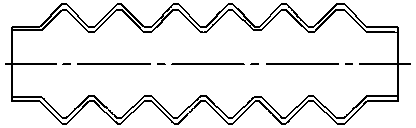

[0038] Such as Figure 1-4 Shown: This embodiment is a rubber bellows model lamination manufacturing equipment, including an upper mold, a lower mold, a middle mold and a core mold, wherein the middle mold is a hollow columnar structure with upper and lower openings, and the upper mold and the lower mold are respectively set At the opening position of the upper and lower ends of the middle mold, the core mold passes through the upper mold, the hollow part of the middle mold and the lower mold. The hollow part of the middle mold is provided with a plurality of ring-shaped rubber sheets and isolation The rubber sheet, the rubber sheet and the spacer are stacked together at intervals. The inner circle of the rubber sheet is close to the outer circle of the core mold, the outer circle of the rubber sheet is close to the inner circle of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com