A kind of centrifugal pump with diversion structure

A technology of centrifugal pumps and deflector surfaces, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve the problems of environmental pollution and large hydrodynamic noise of centrifugal pumps, etc., to reduce pollution, Effect of reducing wear and weakening unsteady flow phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

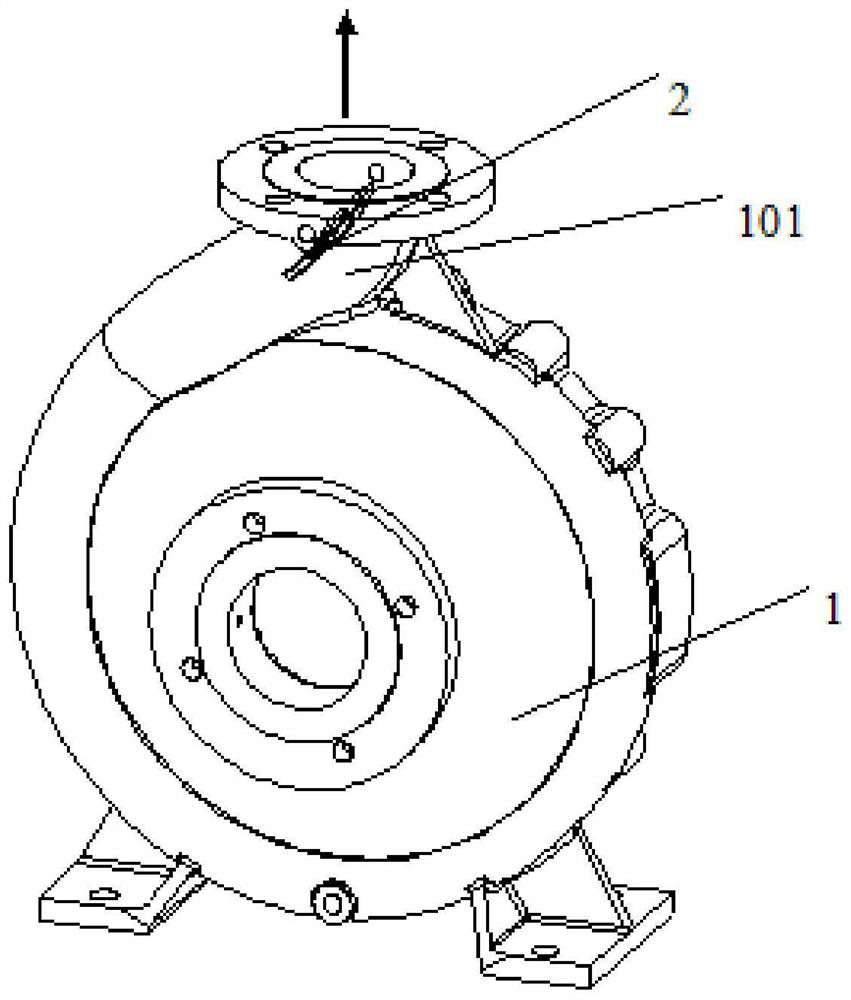

[0045] combine Figure 1-Figure 4 As shown, a centrifugal pump with a guide structure includes a pump body 1 and at least one guide vane, the outlet end of the pump body 1 has a diffuser section 101, and the at least one guide vane is along the preset liquid flow direction set in the diffusion section 101;

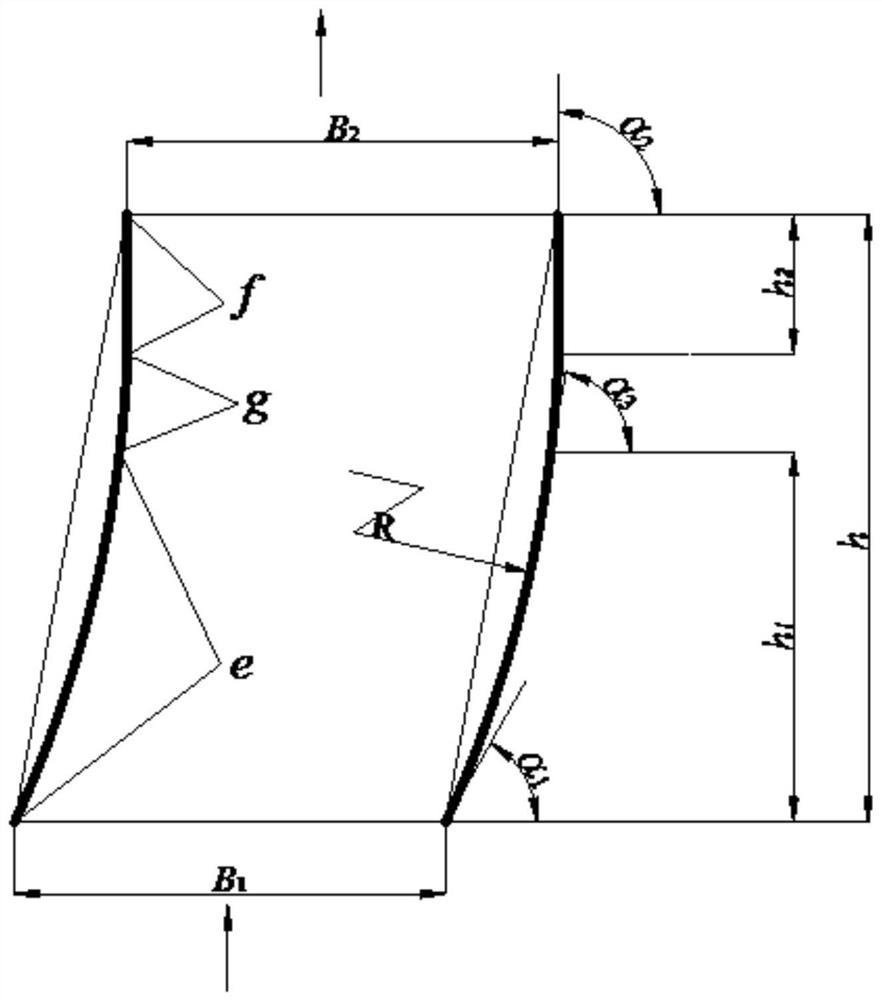

[0046] The guide vane is an arc-arch structure, and the guide vane includes a leading edge guide curve section e, a middle guide curve connecting section g and a trailing edge guide straight section f connected in sequence.

[0047] The guide vane has a first guide surface, the first guide surface is a convex surface of the guide vane, and the first guide surface is provided with a plurality of guide grooves along the preset liquid flow direction.

[0048] The guide grooves are evenly arranged along the profile of the guide vanes, and the section of the guide grooves is perpendicular to the profile of the guide vanes.

[0049] The widths of the plurality of diversion gro...

Embodiment 2

[0071] combined with figure 1 , 2 , 3 and 4, taking a centrifugal pump with a specific speed of 158 as an example, its design parameters are: design flow Qd=330m3 / h, head H=35m, speed n=2792r / min.

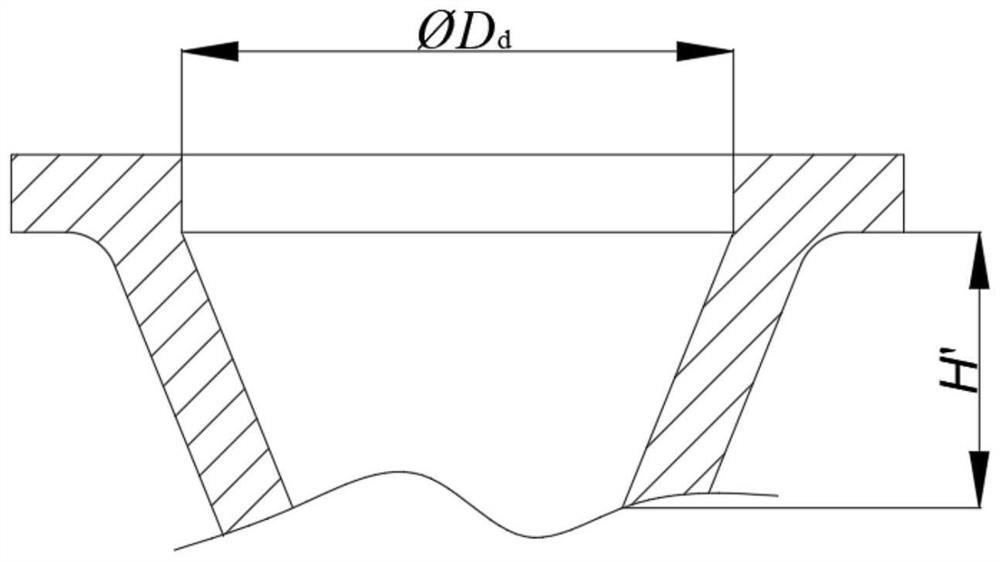

[0072] The outlet diameter D of the diffuser section 101 of the pump body 1 d =280mm, the height of the diffusion section 101 of the pump body 1 H'=300mm, the divergence angle of the flow channel ε=8°;

[0073] The theoretical outlet width of the guide vane is B=65mm, and the proportional coefficient is k=1.0;

[0074] Inlet placement angle of guide vane α 1 =40°, the outlet placement angle of guide vane α 2 =90°, the inclination α of the leading edge guide curve section e of the guide vane 3 =70°.

[0075] Guide vane outlet width B 2 =65mm, inlet width B of guide vane 1 =42mm, the inlet height h=150mm of the guide vane, the thickness t=5mm of the guide vane;

[0076] Profile height h of the leading edge diversion curve segment e 1 = 0.6h = 90mm, profile height h of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com