Multipoint uniform fuel injection system for lean-oil direct-injection combustor

A technology of injection system and combustion chamber, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of excessive thermal stress, shortened combustion chamber life, large temperature gradient of combustion chamber, etc., to achieve low pollutant emission, optimization Injection stability and uniformity, and the effect of improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

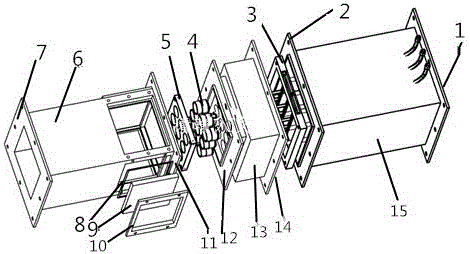

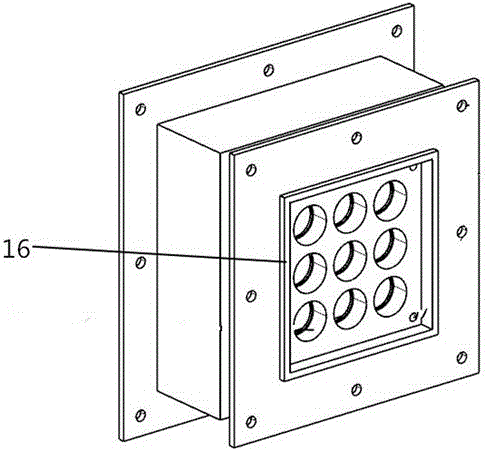

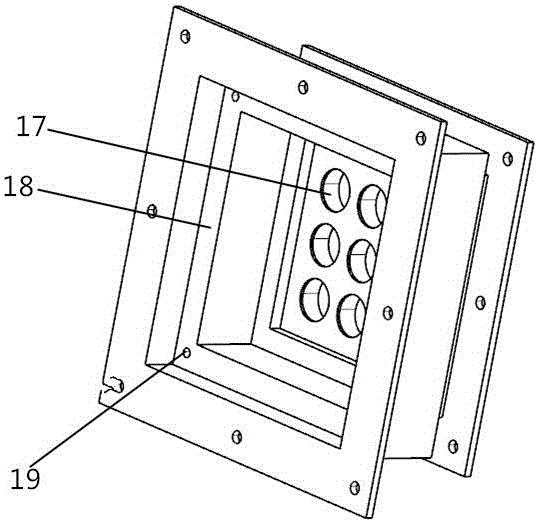

[0034] Such as figure 1 , figure 2 , image 3 , Figure 11As shown, the lean direct injection combustion chamber mainly includes the lean direct injection combustion chamber including the air intake section 15 , the installation section 13 and the combustion chamber body 6 connected in sequence. Wherein the air intake section is a rectangular cross-section air inlet, the air intake section 13 both ends are respectively provided with the air intake section inlet flange 1 and the air intake section outlet flange 2, the air intake section inlet flange 1. Connect the upstream air flow pipe; the upper and lower walls of the air intake section have holes, and the air intake pipe 28 is fixed by welding with the outer wall surface 48 of the air intake pipe. A boss 47 is designed on the outlet flange 2 of the air inlet section to cooperate with the downstream installation secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com