Super-thick low alloy high strength Q345C steel plate and production method thereof

A low-alloy, high-strength, production method technology, applied in the field of medium-thick steel plate production, can solve problems such as special requirements for process equipment and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, the finished steel of extra-thick, low-alloy, high-strength Q345C steel plate with the chemical composition described in Table 1 below is obtained, and each process parameter And the mechanical properties are shown in Tables 4 and 5 below.

[0038] Table 1 Chemical composition of steel in Example 1

[0039] C(%) Si(%) Mn(%) P(%) S(%) Nb+Ni+Cr(%) AlS(%) 0.158 0.30 1.41 0.013 0.003 ≤0.20 0.035

Embodiment 2

[0041] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, the finished product steel of ultra-thick, low-alloy, high-strength Q345C steel plate with the chemical composition described in Table 2 below is obtained, and each process parameter And the mechanical properties are shown in Tables 4 and 5 below.

[0042] Table 2 Chemical Composition of Steel in Example 2

[0043] C(%) Si(%) Mn(%) P(%) S(%) Nb+Ni+Cr(%) AlS(%) 0.160 0.36 1.45 0.013 0.004 ≤0.20 0.034

Embodiment 3

[0045] Through converter smelting, LF refining, vacuum refining, pouring, heating, rolling, controlled cooling, slow cooling, and heat treatment processes, the finished product steel of ultra-thick, low-alloy, high-strength Q345C steel plate with the chemical composition described in Table 3 below is obtained, and each process parameter And the mechanical properties are shown in Tables 4 and 5 below.

[0046] Table 3 Chemical Composition of Steel in Example 3

[0047] C(%) Si(%) Mn(%) P(%) S(%) Nb+Ni+Cr(%) AlS(%) 0.165 0.40 1.39 0.014 0.002 ≤0.20 0.040

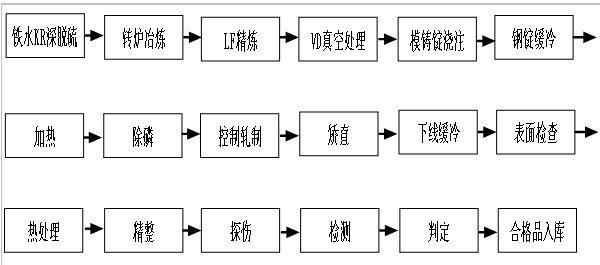

[0048] The process route of the present invention: molten iron KR deep desulfurization→converter smelting→LF refining→VD vacuum treatment→casting ingot pouring→steel ingot slow cooling→heating→phosphorus removal→controlled rolling→controlled cooling→controlled straightening→off-line slow cooling →surface inspection→heat treatment→finishing→flaw detection→testing→judgment→qualified product stor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com