Arc Welding Method And Arc Welding System

An arc welding method and arc welding technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as short circuit between consumable electrodes and base metal, and weld shape damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

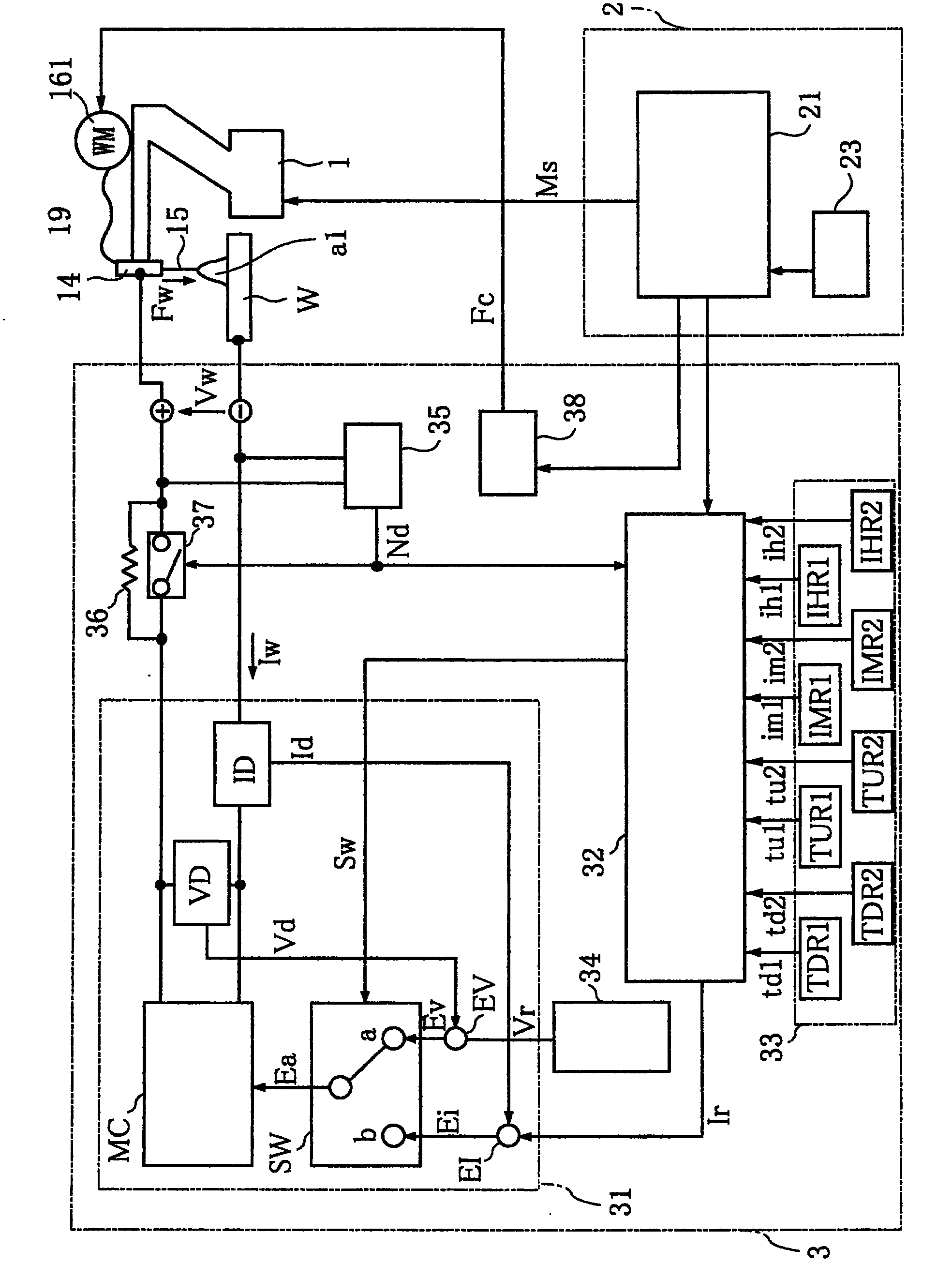

[0020] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

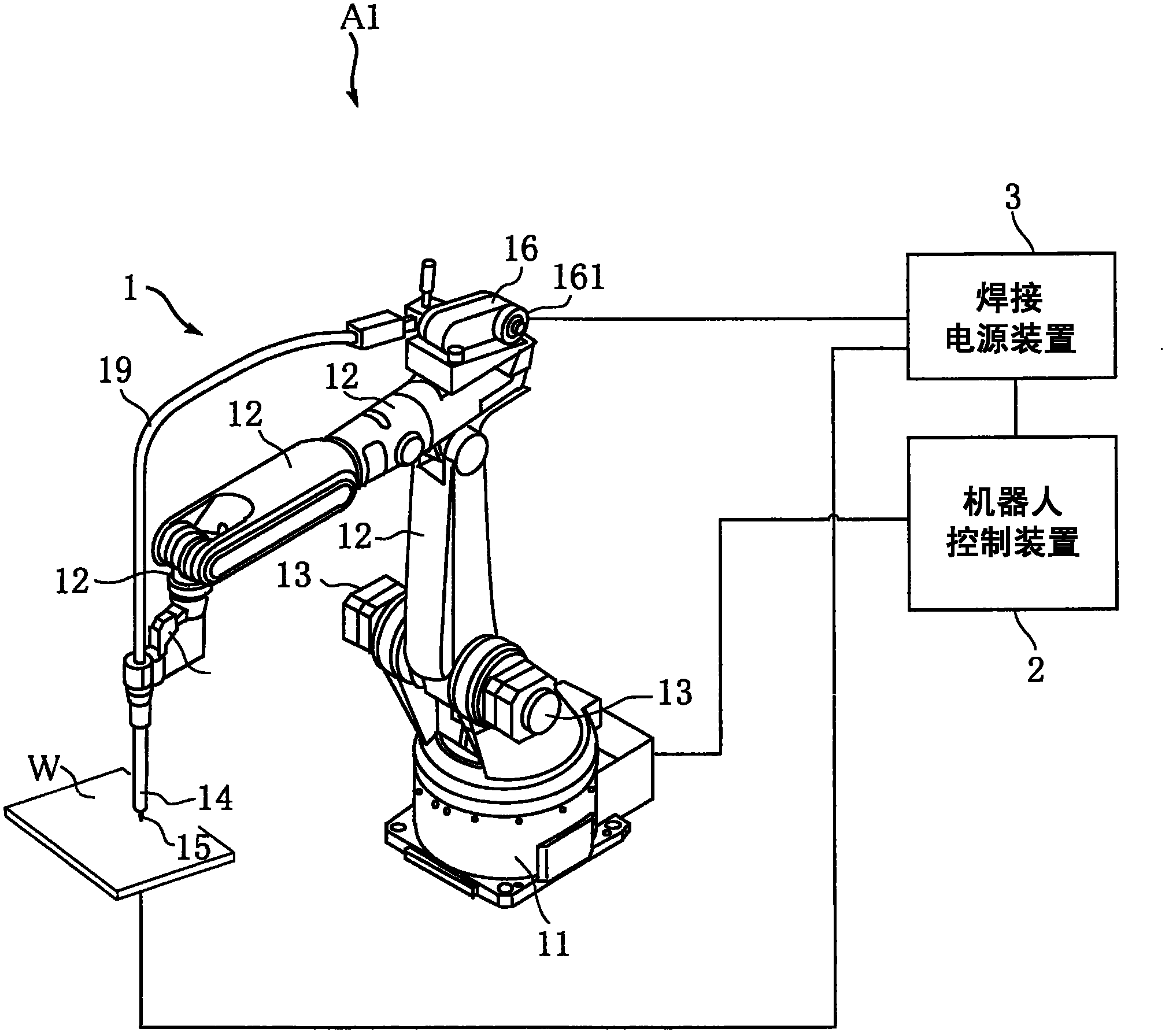

[0021] figure 1 It is a figure which shows the structure of an example of the welding system concerning embodiment of this invention.

[0022] The arc welding system A1 of the present embodiment includes a welding robot 1 , a robot control device 2 , and a welding power source device 3 . The welding robot 1 automatically performs arc welding on the base material W, for example. The welding robot 1 includes a base part 11 , a plurality of arms 12 , a plurality of motors 13 , a welding torch 14 , a wire feeding device 16 , and a linear coil 19 .

[0023] The base member 11 is fixed to an appropriate place such as the ground. Each arm 12 is connected to the base member 11 via a shaft. The welding torch 14 guides the consumable electrode 15 (welding wire) to a predetermined position near the base material W. As shown in FIG. A shielding gas nozzle (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com