Preparation method for ethanol

An ethanol and steam technology, which is applied in the directions of biofuel and fermentation, can solve the problems of low ethanol yield, etc., and achieve the effects of controlling the degree of liquefaction, improving the yield and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

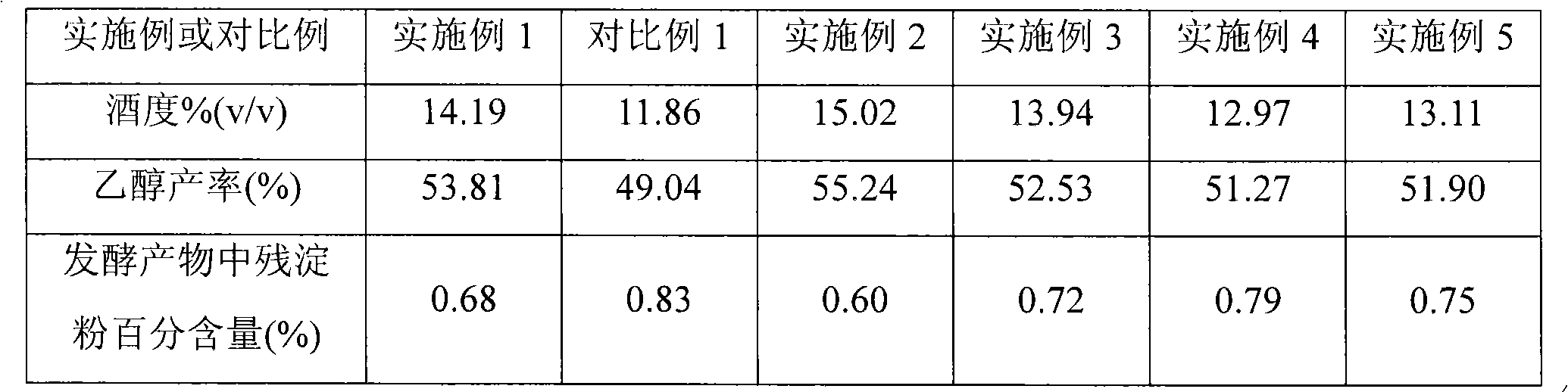

Examples

preparation example Construction

[0011] According to the present invention, the method for preparing ethanol comprises enzymatically hydrolyzing starchy raw materials and fermenting the obtained enzymolyzed products, wherein the method for enzymatically hydrolyzing starchy raw materials includes the following steps:

[0012] (1) Mix the starch slurry obtained from the starchy raw material with some enzymes to obtain a mixture, and contact the mixture with steam under conditions such that the temperature of the mixture after contact with the steam is 75-95° C., preferably 80-90° C. , and kept at this temperature for 30-90 minutes, preferably 50-80 minutes;

[0013] (2) The mixture contacted with steam in step (1) is contacted with steam again, the condition of contact is such that the temperature of the mixture contacted with steam again is 100-120°C, preferably 100-110°C, and at this temperature Keep it down for 1-10 minutes, preferably 5-9 minutes;

[0014] (3) The temperature of the mixture in step (2) aft...

Embodiment 1

[0041] This example is used to illustrate the method of the present invention for preparing ethanol using corn raw material.

[0042] (1) Grinding of corn raw materials

[0043] 100 parts by weight of corn (with a moisture content of 14% by weight) were pulverized to obtain a pulverized product with an average particle diameter of 1500 microns, and the pulverized product was mixed with 220 parts by weight of water to obtain a starch slurry.

[0044] Determine the total sugar content in the mixed slurry according to the total sugar direct titration method of GBT 15038-2006, wherein the weight of the total sugar is 1.11 times the weight of the starch in the crushed product, therefore, the total sugar content can be determined by the national standard method According to the formula: starch content=total sugar / 1.11, the calculated starch content in the pulverized product is 63 parts by weight / 100 parts by weight corn.

[0045] (2) Enzymolysis

[0046] At 50 DEG C, the starch sl...

Embodiment 2

[0060] This example is used to illustrate the method of the present invention for preparing ethanol using corn raw material.

[0061] (1) Grinding of corn raw materials

[0062] 100 parts by weight of the same corn raw material as in Example 1 were pulverized to obtain a pulverized product with an average particle diameter of 1800 microns, and the pulverized product was mixed with 210 parts by weight of water to obtain a starch slurry.

[0063] (2) Enzymolysis

[0064]At 60°C, the starch slurry obtained in step (1) is mixed with the enzyme of 35% by weight of the total weight of the enzyme to obtain a mixture, and the mixture is sprayed into contact with steam at 150°C in an injector (steam and mixture The ratio is 0.08:1), the contact time is 6 seconds, so that the temperature of the mixture after contacting with steam is 90°C, the pH value is adjusted to 5, and maintained at this temperature for 80 minutes;

[0065] The above-mentioned mixture after being contacted with st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com