Novel blast furnace iron making technology with slag iron discharged from center of furnace bottom

A blast furnace ironmaking and slag discharge technology, which is applied in the direction of discharge devices, can solve problems such as uneven discharge into the furnace, increased air intake resistance at the tuyere, and impossibility of complete overlap of the probe line curves, etc., to achieve safety assurance and prolongation. Effect of blast furnace life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

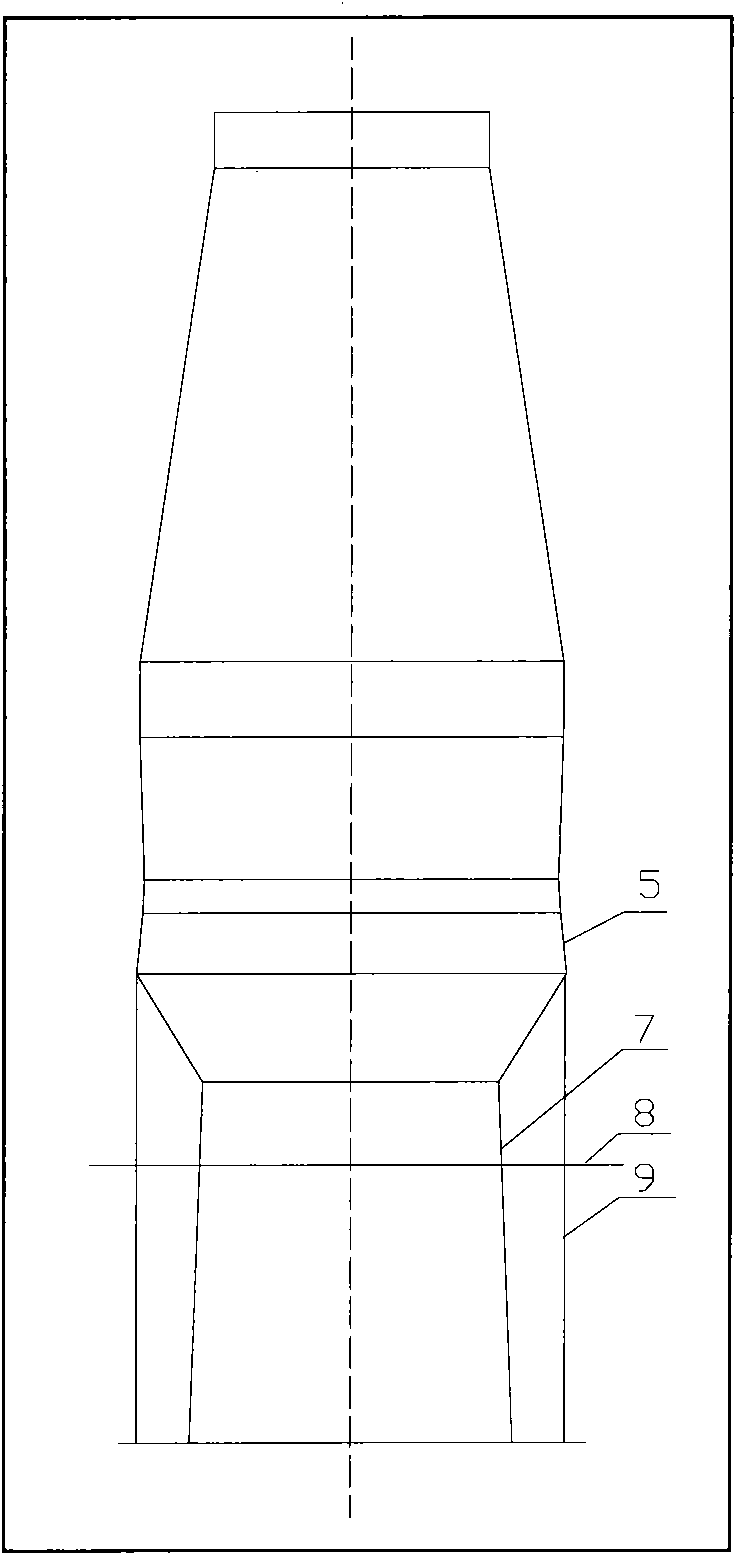

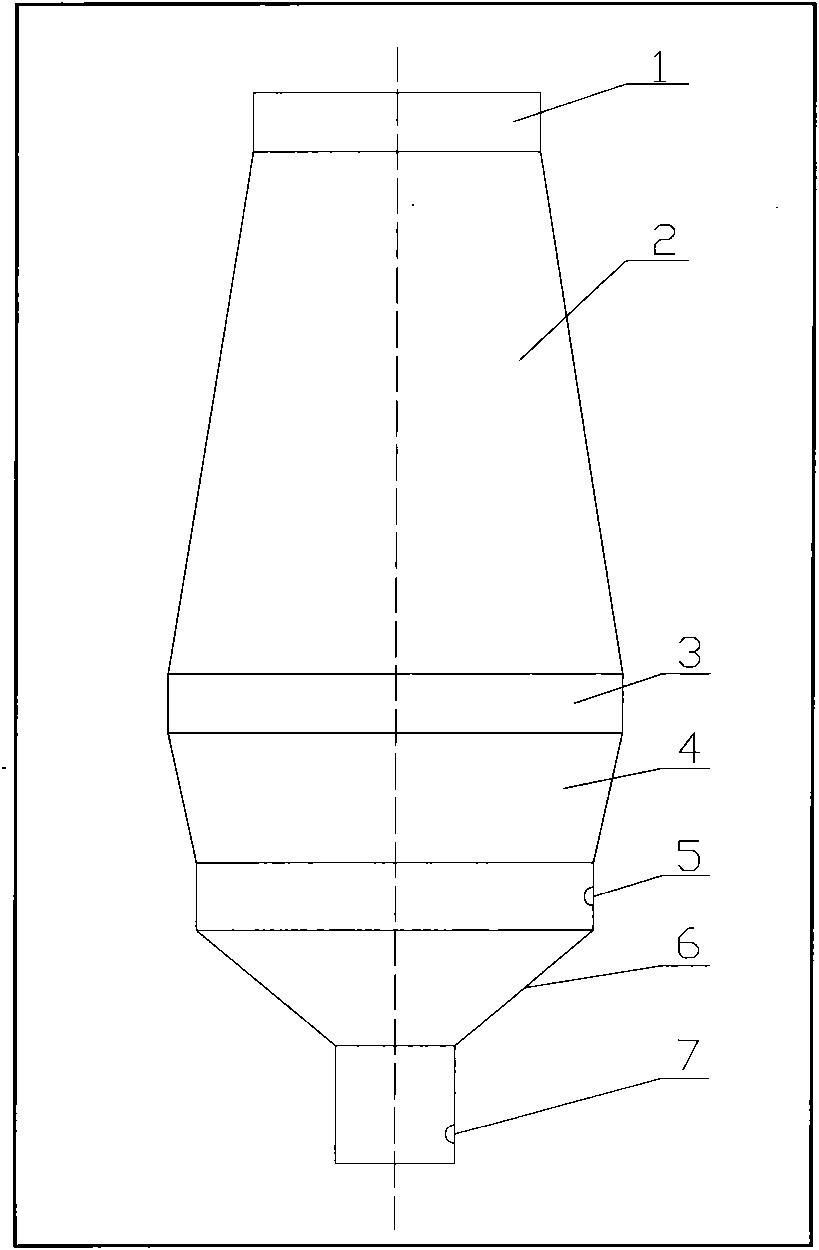

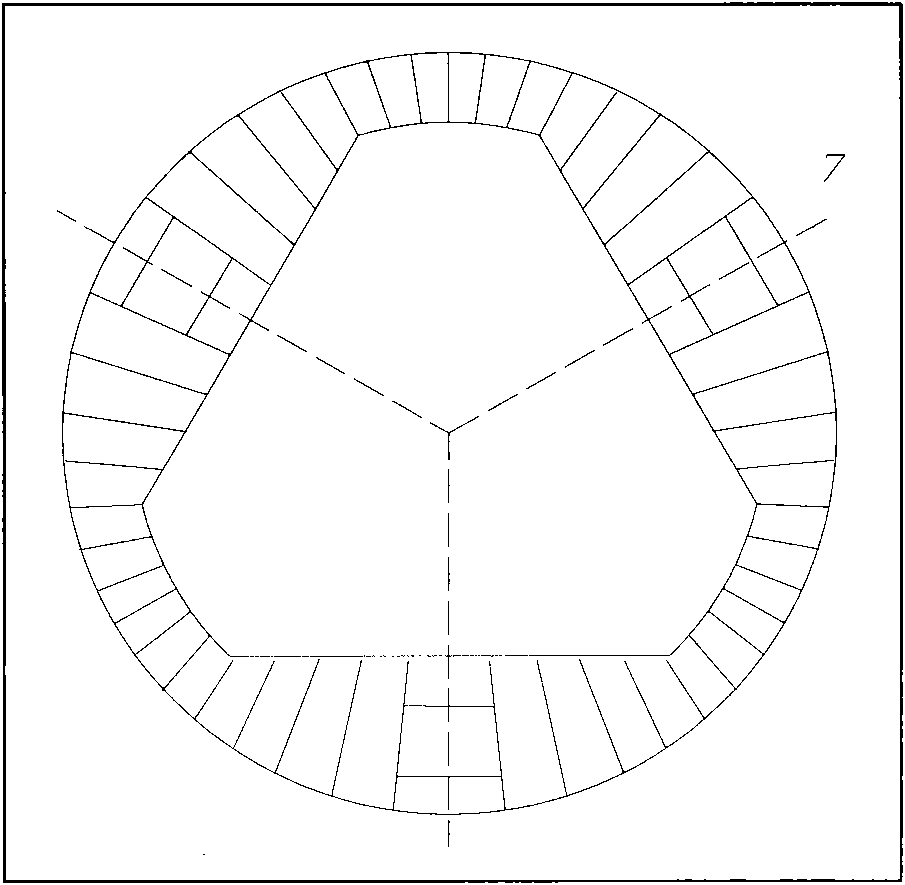

[0027] exist figure 1 and figure 2 The middle furnace throat (1), furnace body (2), furnace waist (3), bosh (4) and tuyere (5) are the same as the current blast furnace structure; the hearth wall (6) below the tuyere (5) faces the The inclination of the center and the inclination angle with the horizontal direction are mainly based on the size of the casthouse space, which meets the needs of the layout of the casting equipment and the treatment of slag and iron in front of the furnace, and avoids the erosion of the furnace lining of the inclined section by hot air. The top of the vertical section of the cylinder is connected; the iron hole (7) is arranged on the side wall of the vertical section, and the casthouse platform (8) is the same as the currently set casthouse platform, and the iron hole (7) and the casthouse platform (8) The elevation is equivalent to that of the current blast furnace, that is, to meet the needs of slag iron treatment in front of the furnace, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com