Oil limiter of diesel engine

A diesel engine and oil-limiting technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as high fuel consumption, black smoke, and environmental pollution, and achieve improved ignition sensitivity, good reliability, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

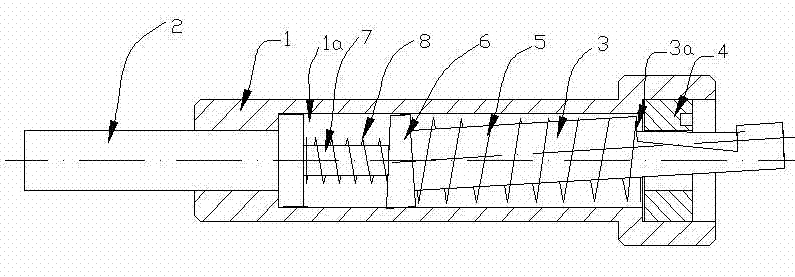

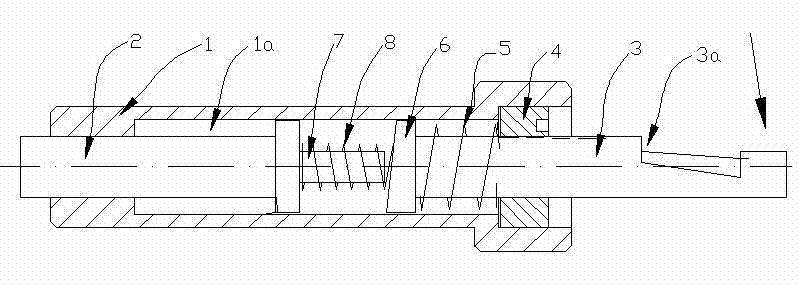

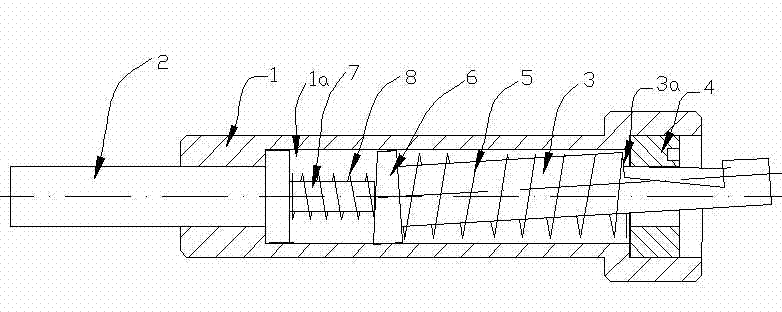

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] See figure 1 , figure 2 and image 3 : A diesel engine oil limiter, comprising an adjustment seat 1, an adjustment rod 2, a push rod 3 and a limit ring 4, an installation through hole 1a is arranged in the axial direction on the adjustment seat 1, and the installation through hole 1a Install the adjustment rod 2, the push rod 3 and the limit ring 4 sequentially from left to right, wherein the limit ring 4 is fixed on the right end of the installation through hole 1a, and the left part of the adjustment rod 2 protrudes The right part of the installation through hole 1a is stuck in the installation through hole 1a and pushed against the left end of the push rod 3, that is, the adjustment rod 2 has a "ten"-shaped structure, and the left side of the vertical part Stretch out the installation through hole 1a, the right part is stuck in the installation through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com