Installing structure for plasma generator of burner

A generator, low-temperature plasma technology, applied in burners, burners for burning powder fuel, combustion methods, etc., can solve problems such as the influence of the service life of plasma generators, improve cooling effect, facilitate circulation, disassembly and assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

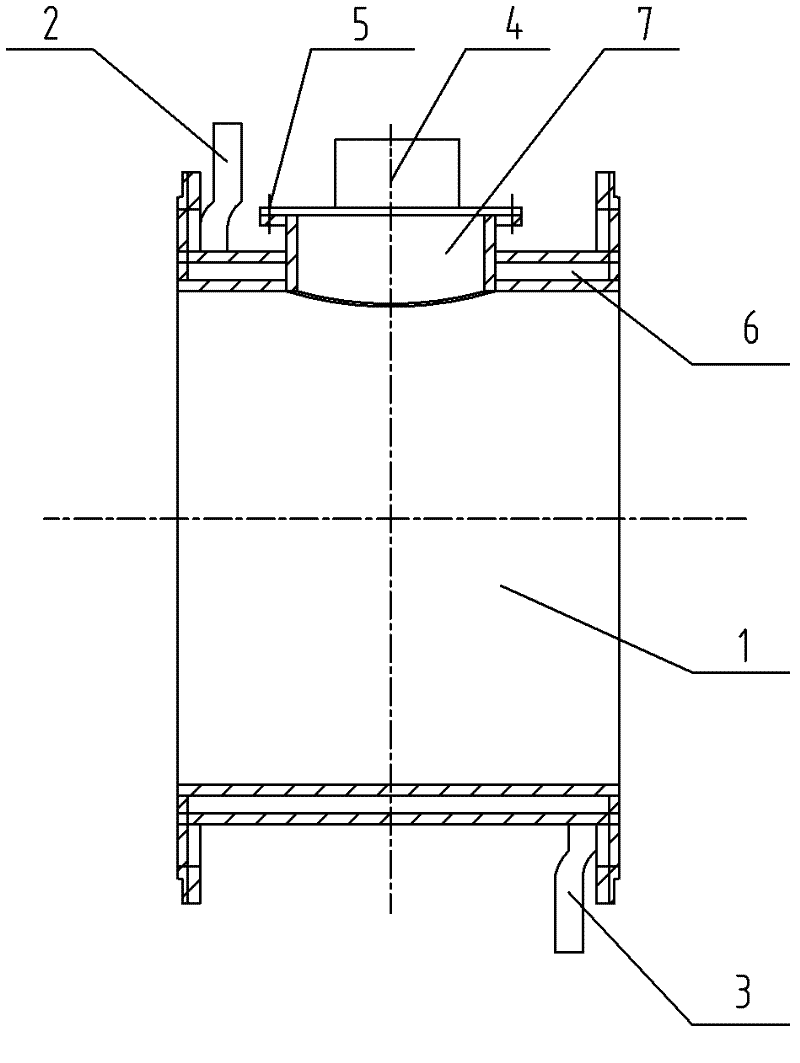

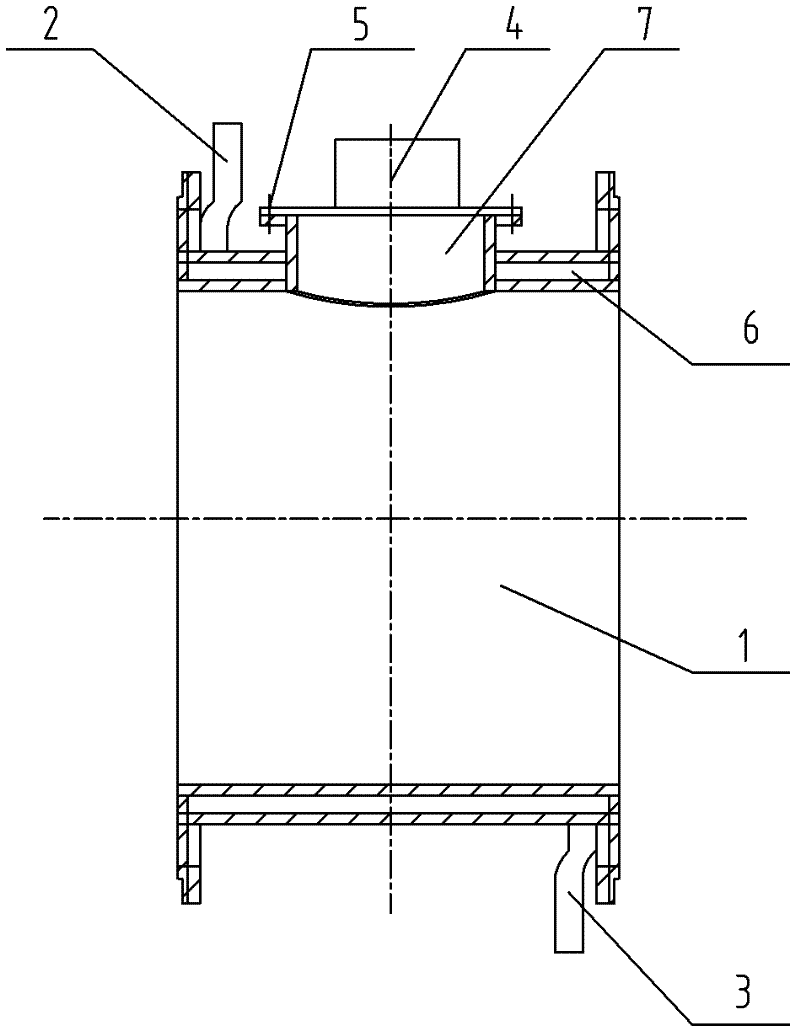

[0012] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the installation structure of the plasma generator of the burner of the present invention includes a main section of the air pulverized coal circulation and a plasma installation pipe connected through the main section of the air pulverized coal circulation, and the plasma installation pipe is fixed with the plasma generator. And the plasma flow injection port of the plasma generator is set facing the main section of the air pulverized coal circulation, and the main air pulverized coal circulation pipe is built in the cooling pipe, and the gap between the air pulverized coal circulation main pipe and the cooling pipe is set as a cooling chamber, which is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com