Heating furnace

A heating furnace and furnace body technology, which is applied in the field of heating furnaces, can solve the problems of poor cooling effect of the primary cooling box, poor product uniformity, and low work efficiency, so as to save labor time, improve cooling effect, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

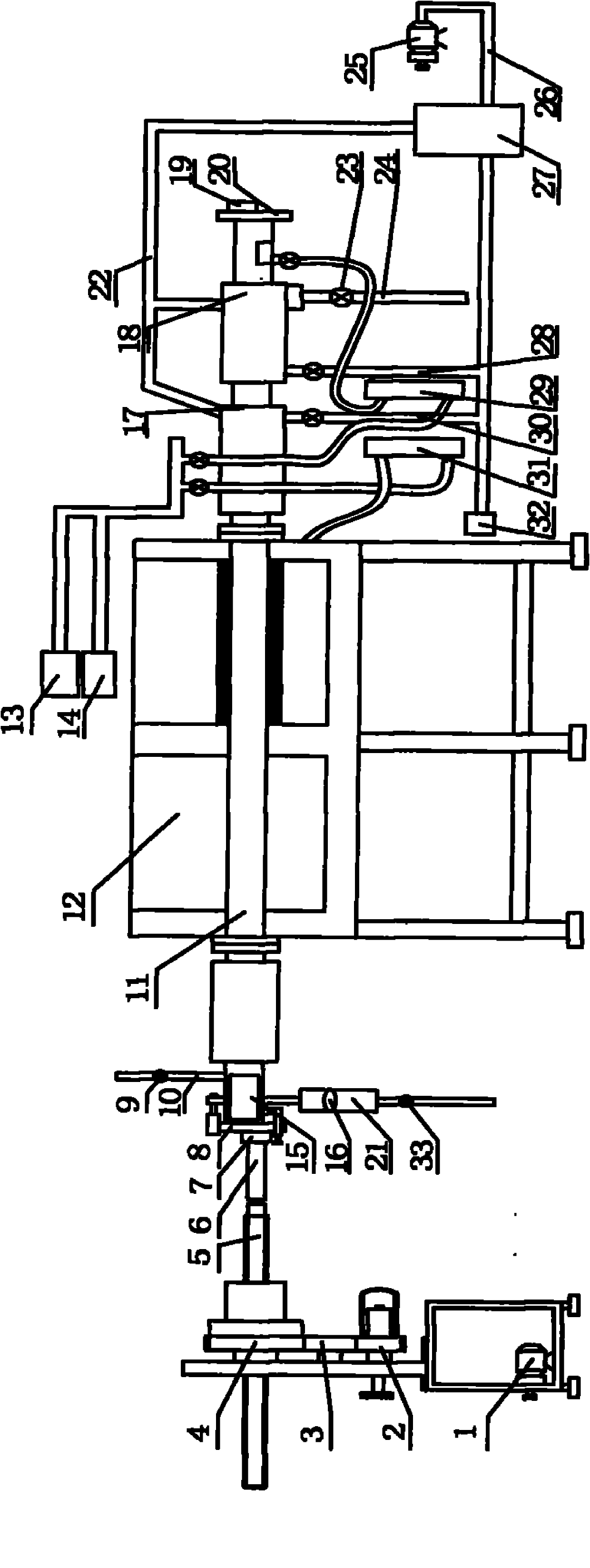

[0014] As shown in Figure 1, a heating furnace of the present invention includes a charging boat 15 placed in the inner cavity 11 of the furnace, a furnace body 12, a propulsion device, a blowdown mechanism, a grading cooling device, a two-way gas supply device, a feeding Door 8 and discharge door 20, the front end of the furnace body 12 is provided with a feed door 8, and the end is provided with a discharge door 20, the propulsion device includes a clutch device, a threaded push rod 5 and a push rod 6, and the clutch device Including gear a2, gear b3, gear c4 and motor 1, the graded cooling device includes a primary cooling box 17 and a secondary cooling box 18, and the dual-way air supply equipment includes an air supply source 13, a backup air supply source 14, The gas flow meter 29 and the spare gas flow meter 31, the motor 1 is connected to the gear a2, the gear b3 is connected to the gear a2, the gear c4 is connected to the gear b3, and the gear c4 is connected to the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com