Device for measuring vertical position of workpiece bench

A vertical position and workpiece table technology, applied in the field of position measurement devices, can solve problems such as cosine errors, achieve high accuracy, reduce factors, and achieve high-precision measurement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In order to facilitate the description and highlight the present invention, related components in the prior art are omitted from the drawings, and the description of these well-known components will be omitted.

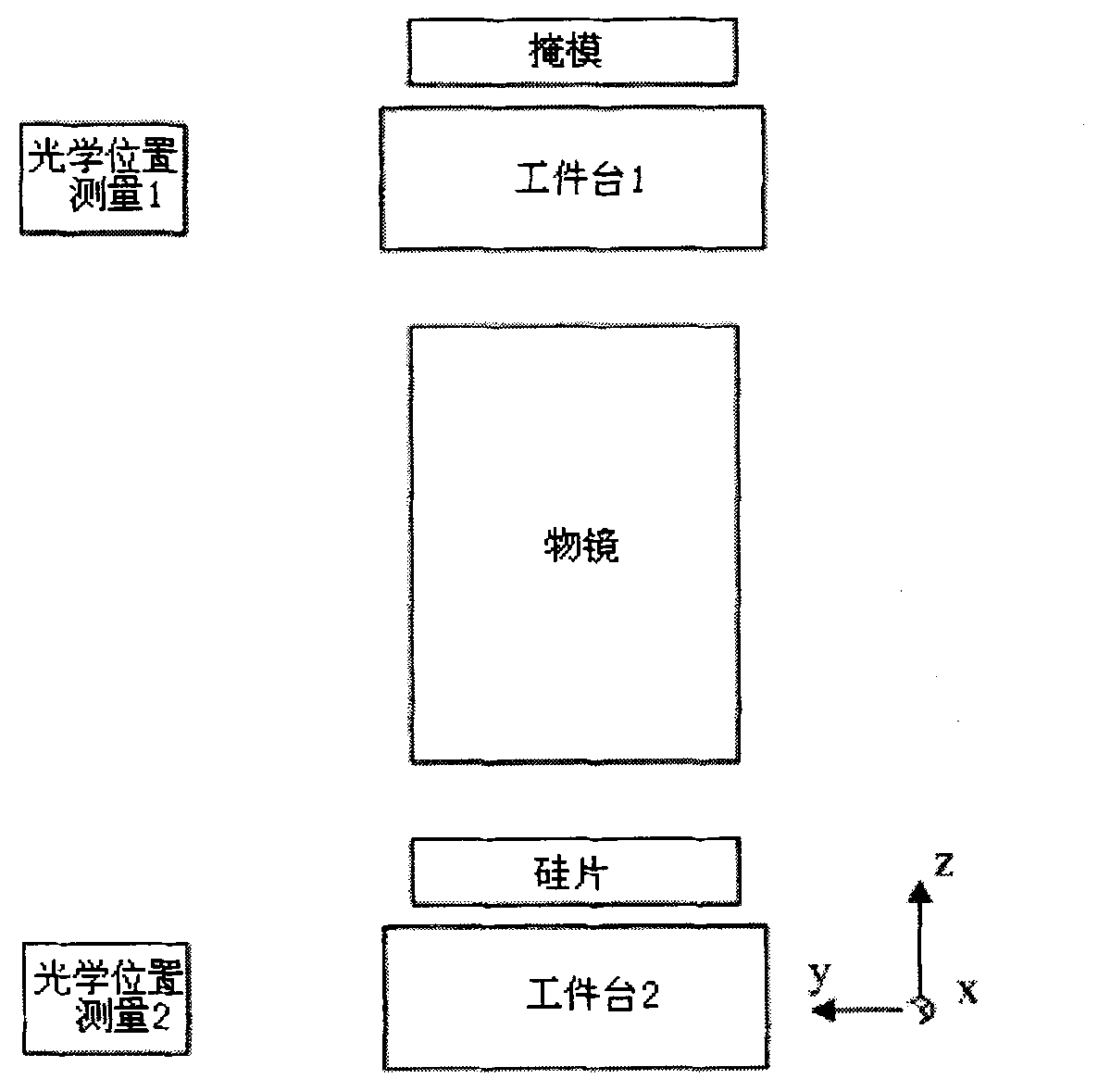

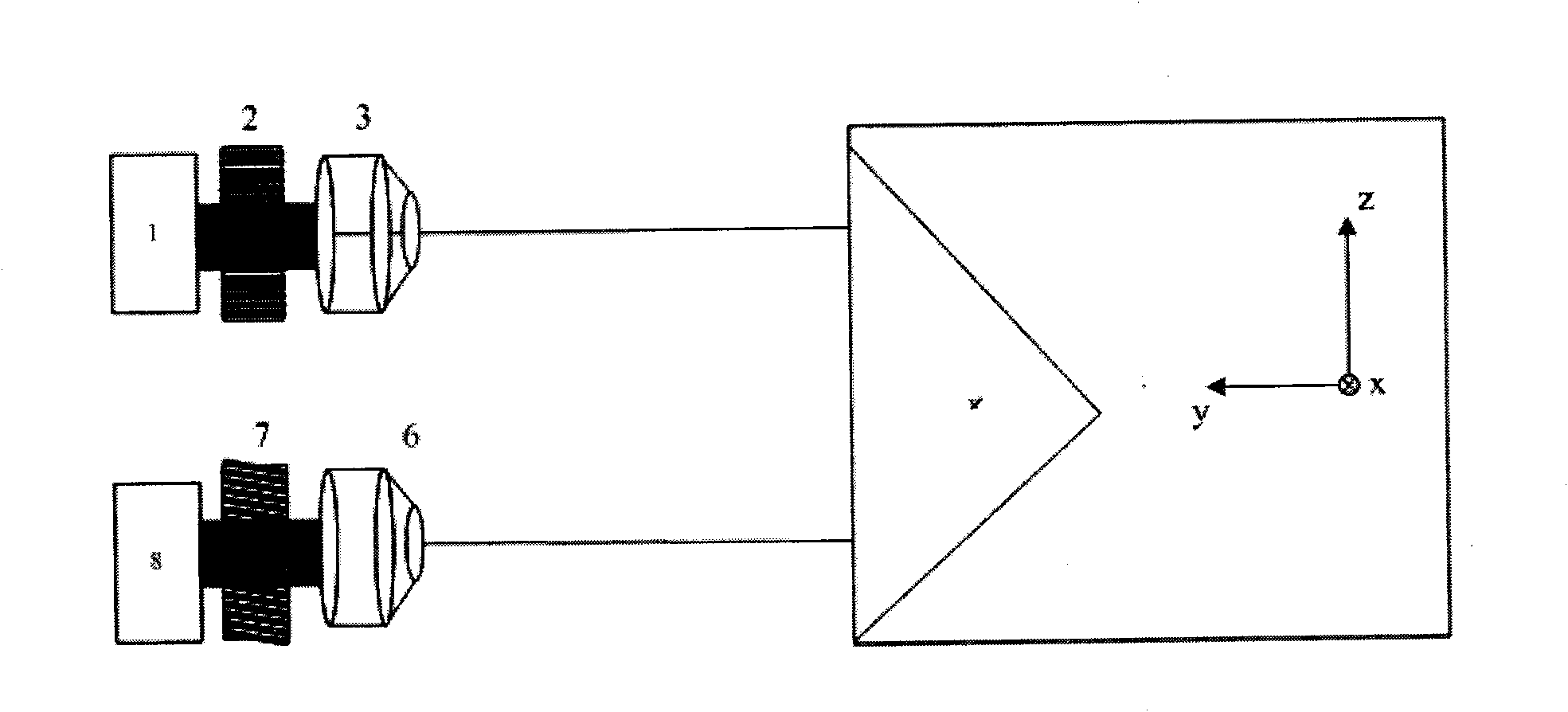

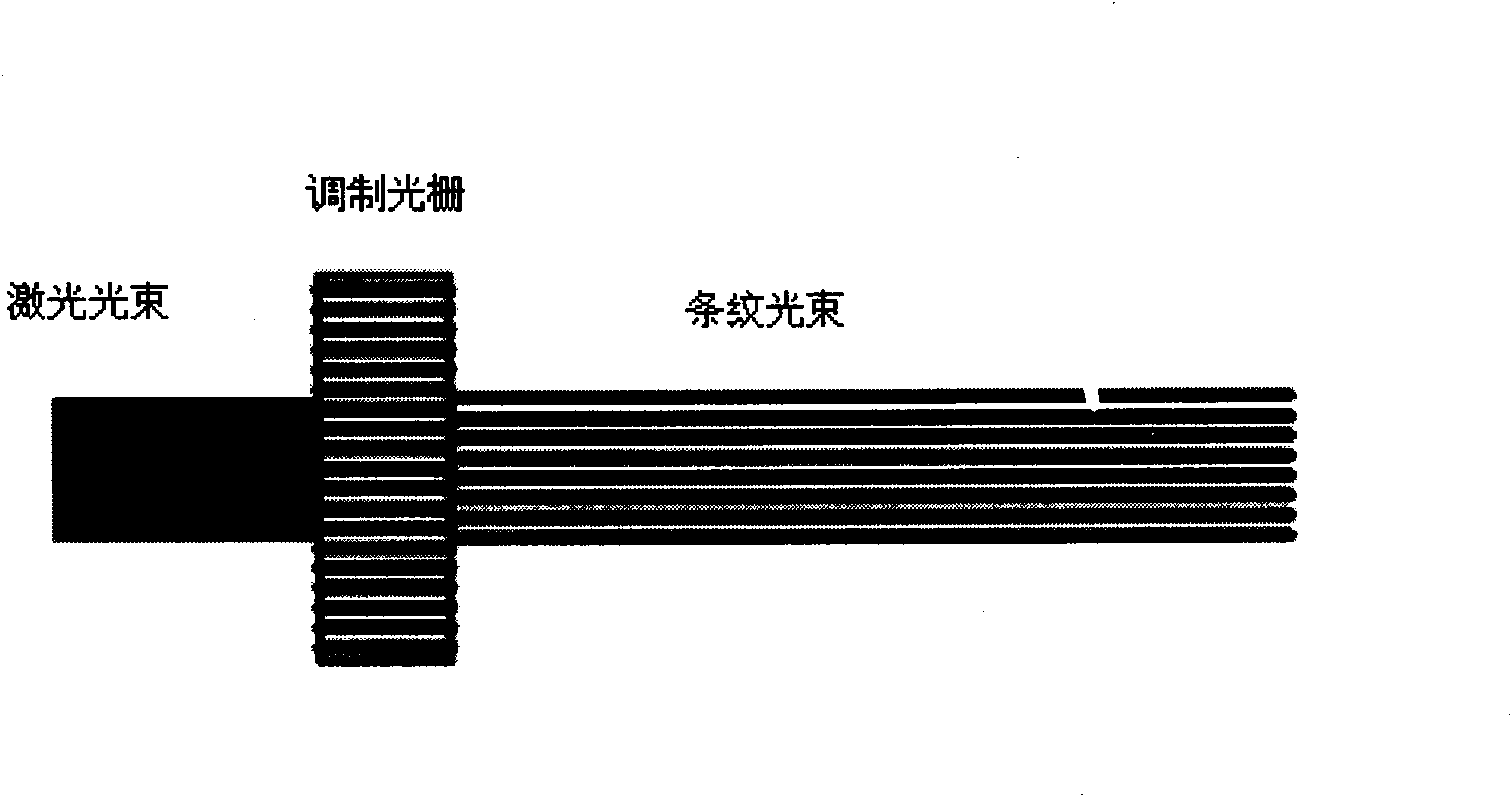

[0037] Such as figure 1 As shown, the measurement system of the present invention can be used to measure the optical position of a workpiece table in a lithography machine. figure 2 Shown is a measurement system constructed in accordance with the present invention. The system includes a laser 1, a modulation grating 2, a first microscope objective lens 3, a corner reflector 4 mounted on one side of a workpiece stage 5, a second microscope objective lens 6, a detection grating 7 and a detector 8. Among them, the modulation grating 2 and the detection grating 7 are both transmission gratings.

[0038] After the light beam generated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com