Electric motor with dual-rotor driving wheel

A dual-rotor, wheel motor technology, applied in the field of electric vehicles, can solve the problems of low cost, poor low-speed performance, and difficult processing of brushed motors, and achieve good reversing performance, strong overload capacity, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the application is further described:

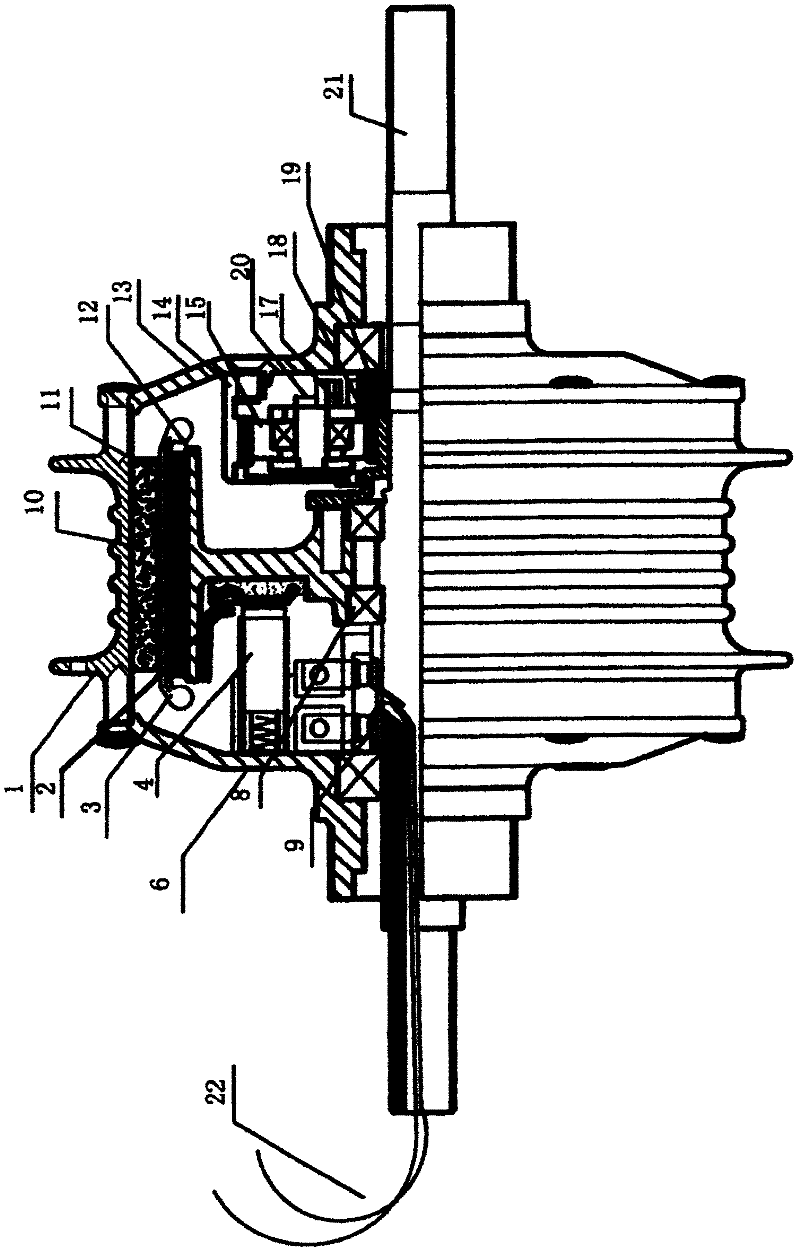

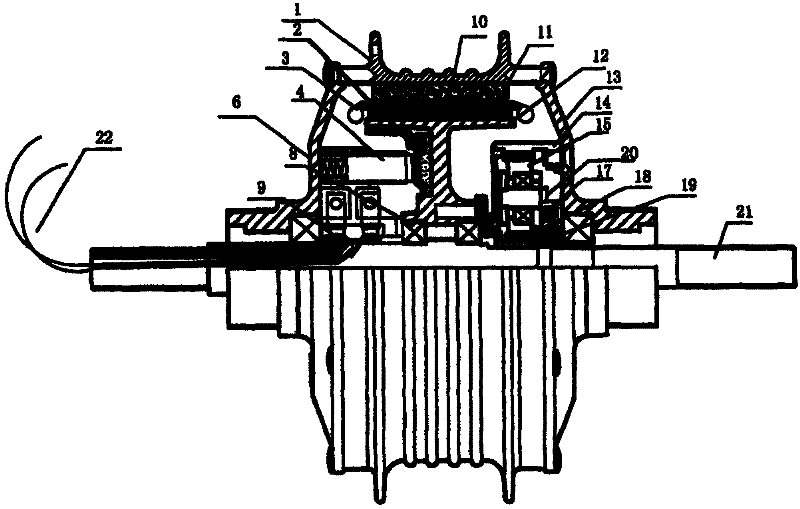

[0015] Referring to the accompanying drawings, the double-rotor drive wheel motor includes a motor shaft 21, a hub shell, an inner rotor frame 12 and a planetary reduction mechanism, and the hub shell includes a motor iron shell 1 and a permanent magnet fixed to the inner ring of the motor iron shell 1 10 and the left end cover 6 and right end cover 13 fixedly connected with the motor iron shell 1, the left end cover 6 and the right end cover 13 are fixed on the motor shaft 21 through bearings, so that the hub shell constitutes the outer rotor of the motor, and the inner rotor frame 12 is fixed with a ring-shaped yoke 11, and the outer surface of the yoke 11 is fixed with an armature 3. The inner rotor frame 12 is connected with the motor shaft 21 through the inner rotor bearing 8 to form an inner rotor. One side of the inner rotor frame 12 Fixedly connected to the comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com