Element wire contact prevention member and method for maintenance of heater device

A heater and wire technology, used in furnace heating elements, heating element materials, electrical components, etc., can solve the problems of heater wire deformation, spark disconnection, contact welding and other problems, and achieve the effect of preventing mutual contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

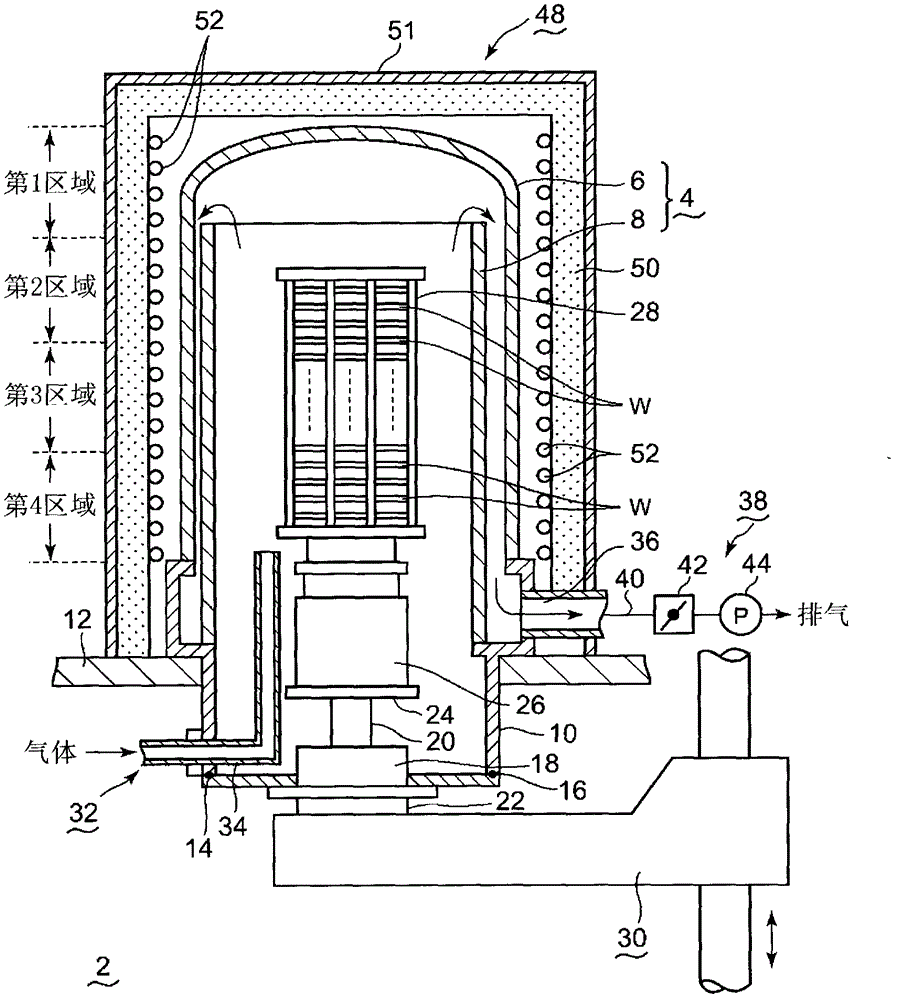

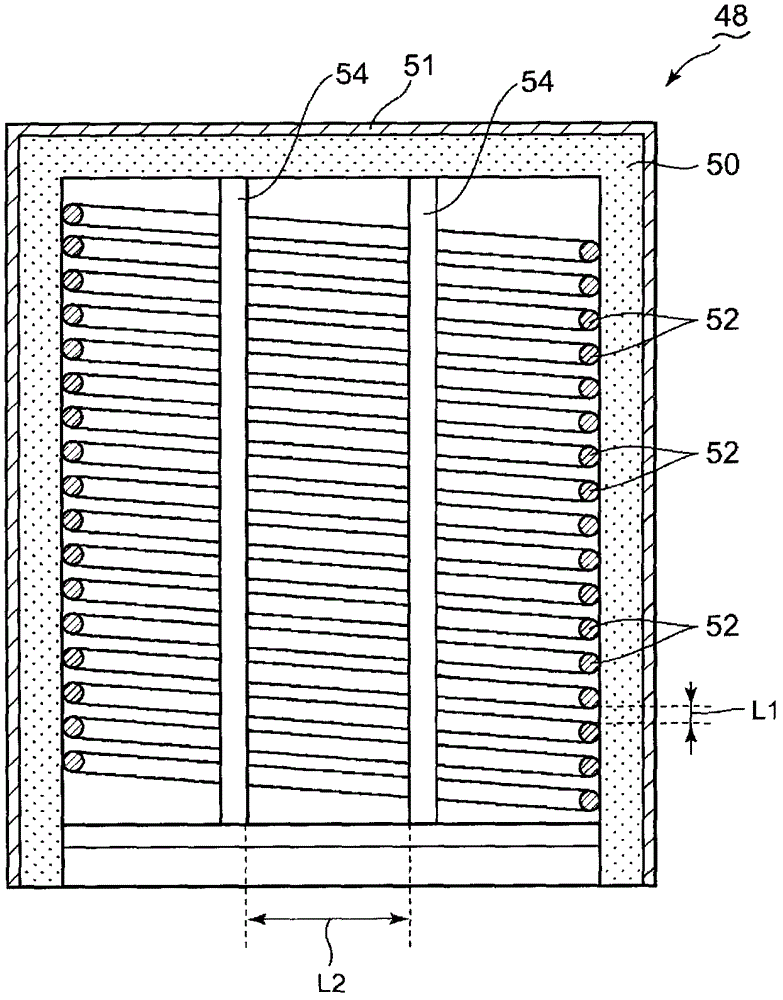

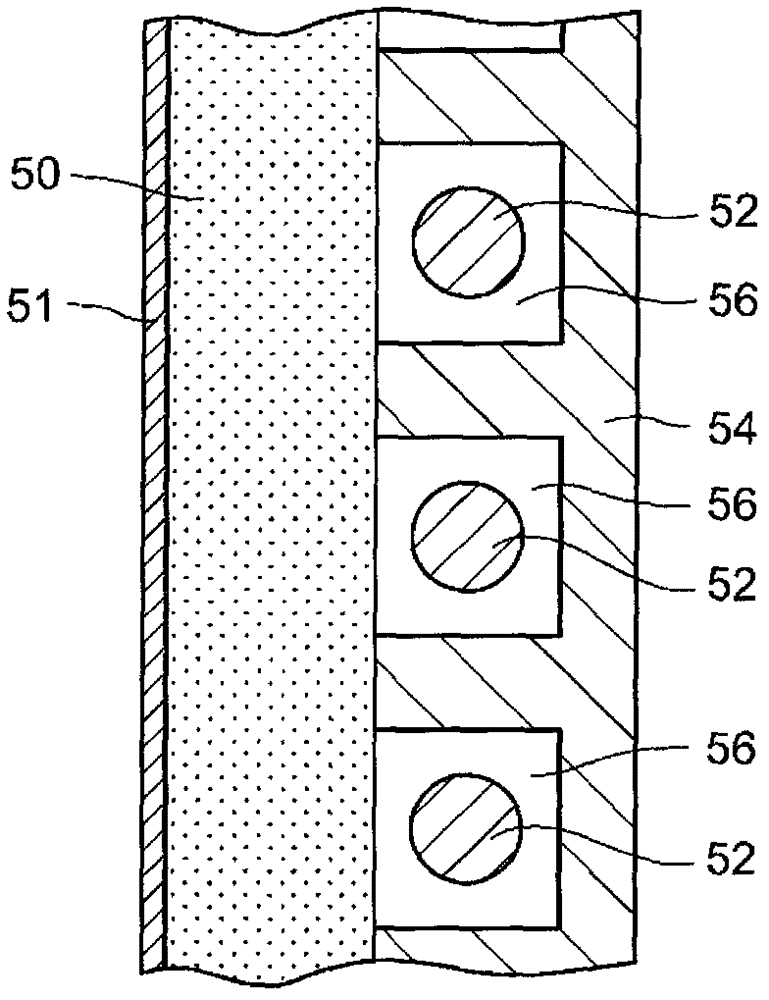

[0025] Next, an embodiment of the maintenance method of the wire contact preventing member and the heater device according to the present embodiment will be described in detail with reference to the attached drawings. figure 1 It is a schematic configuration diagram showing an example of a heat treatment device having a heater device to which the wire contact preventing member of the present invention is applied, figure 2 is a sectional view showing the heater unit, image 3 is an enlarged sectional view showing a part of the heater device, Figure 4 It is a perspective view which shows an example of the wire contact prevention member of this invention. Here, a case where a semiconductor wafer is used as an example to be heated will be described.

[0026] First, the heat treatment device will be described. Such as figure 1 As shown, this vertical heat treatment apparatus 2 includes a cylindrical processing container 4 whose longitudinal direction is arranged in a vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com