Electric control breast pump

An electric control, breast pump technology, applied in breast pump and other directions, can solve problems such as mixing into milk, influence, easy damage to the orifice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

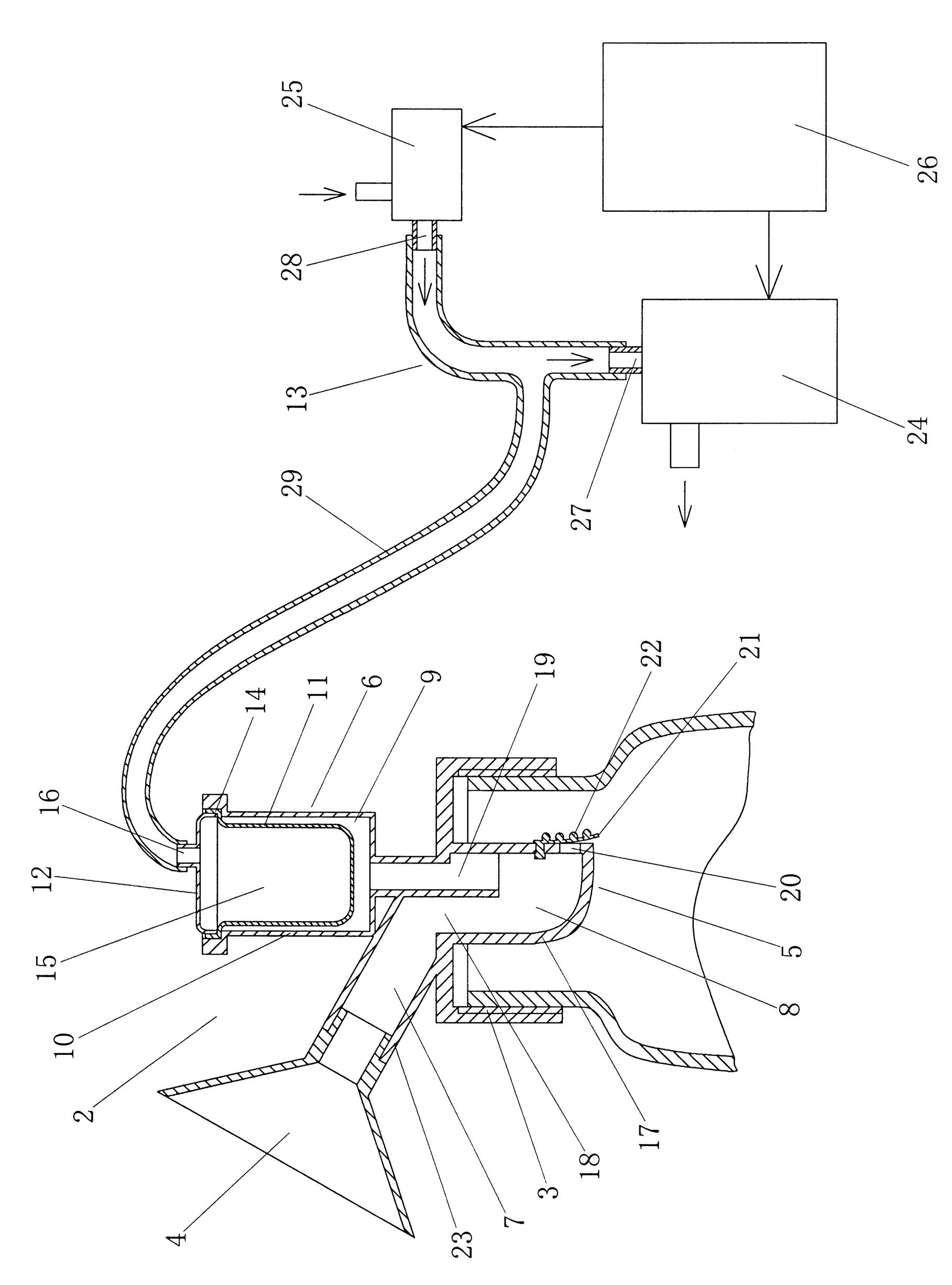

[0024] refer to figure 1 , the electric control breast pump includes a feeding bottle 1 and a breast pump main body 2, and the feeding bottle 1 and the breast pump main body 2 are connected together by threads 3, wherein the breast pump main body 2 includes a bottle cap seat 3 and a breast pumping part 4 , connect the milk valve 5 and the negative pressure generating part 6, the bottle cap seat 3 is connected to the bottle mouth of the feeding bottle 1 through the thread 3, the milk sucking part 4 and the negative pressure generating part 6 are arranged on the top of the bottle cap seat 3, and the milk connecting valve 5 is arranged on the At the bottom of the bottle cap seat 3, the sucking part 4 communicates with the valve chamber 8 of the milk valve 5 through the milk passage 7, and the negative pressure chamber 9 of the negative pressure generating part 6 communicates with the valve chamber 8 of the milk valve 5. It is characterized in that : the negative pressure generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com