Electrocoating fixture

An electrophoretic coating and fixture technology, used in electrolytic coatings, electrophoretic plating, coatings, etc., can solve problems such as small gaps at the hanging point, inconvenient installation and hanging, and impact on anti-corrosion performance, to improve consistency and uniformity. , Improve the effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

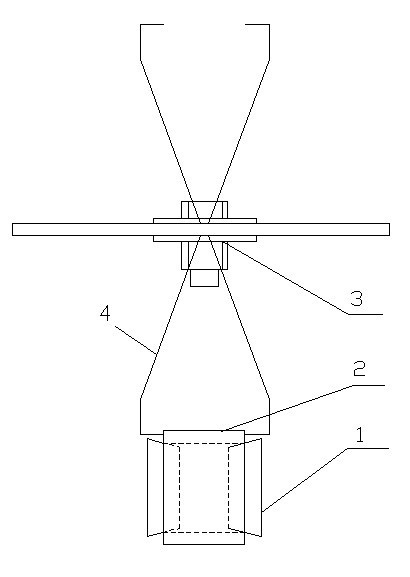

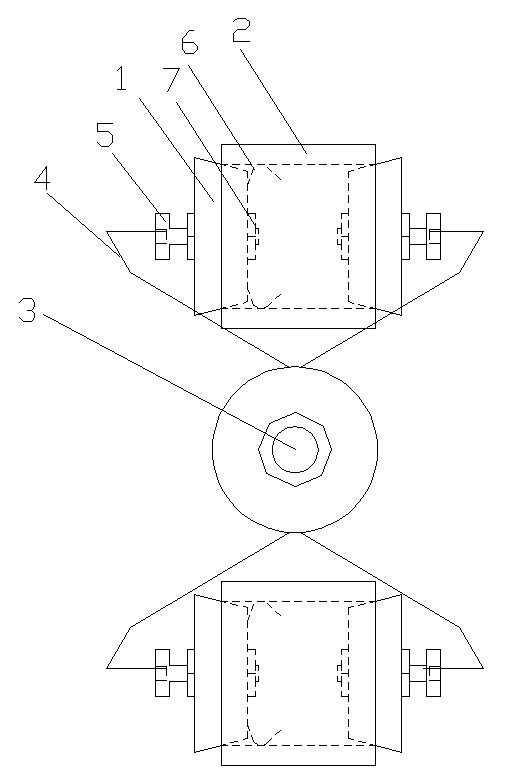

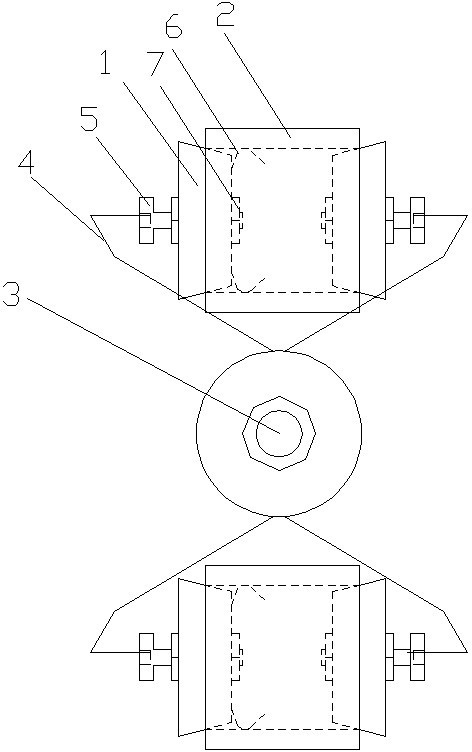

[0015] like figure 2 As shown, the electrophoretic coating fixture includes two plugs 1, a jumper 4, and a hanger 3, and the jumper 4 is fixed on the hanger 3.

[0016] A hole is drilled in the middle of the plug 1, the hexagon socket metal screw rod 5 passes through the plug 1, and the elastic conductive reed 6 is fixed by a nut 7 at the inner end of the plug 1.

[0017] When in use, the plug 1 is mounted on both ends of the workpiece 2, the elastic conductive reed 6 is stuck on the inner wall of the workpiece 2, and the clip spring 4 is stuck on the outer plane of the hexagonal metal screw 5 on the plug to block the entire workpiece 2, and the entire workpiece Just hang on the hanger 3 like this.

[0018] Since the workpieces without plating in the inner holes of the fixtures according to the invention can form a uniform and consistent co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com