Hoisting construction method for steel roof truss of main power house of power plant and special hoisting device

A technology of lifting device and construction method, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of increasing the difficulty of large-scale equipment transfer, heavy large-scale lifting equipment, and prolonging the time of hoisting, so as to reduce the Re-investment and frequent transfers, improved construction effects, and guaranteed safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

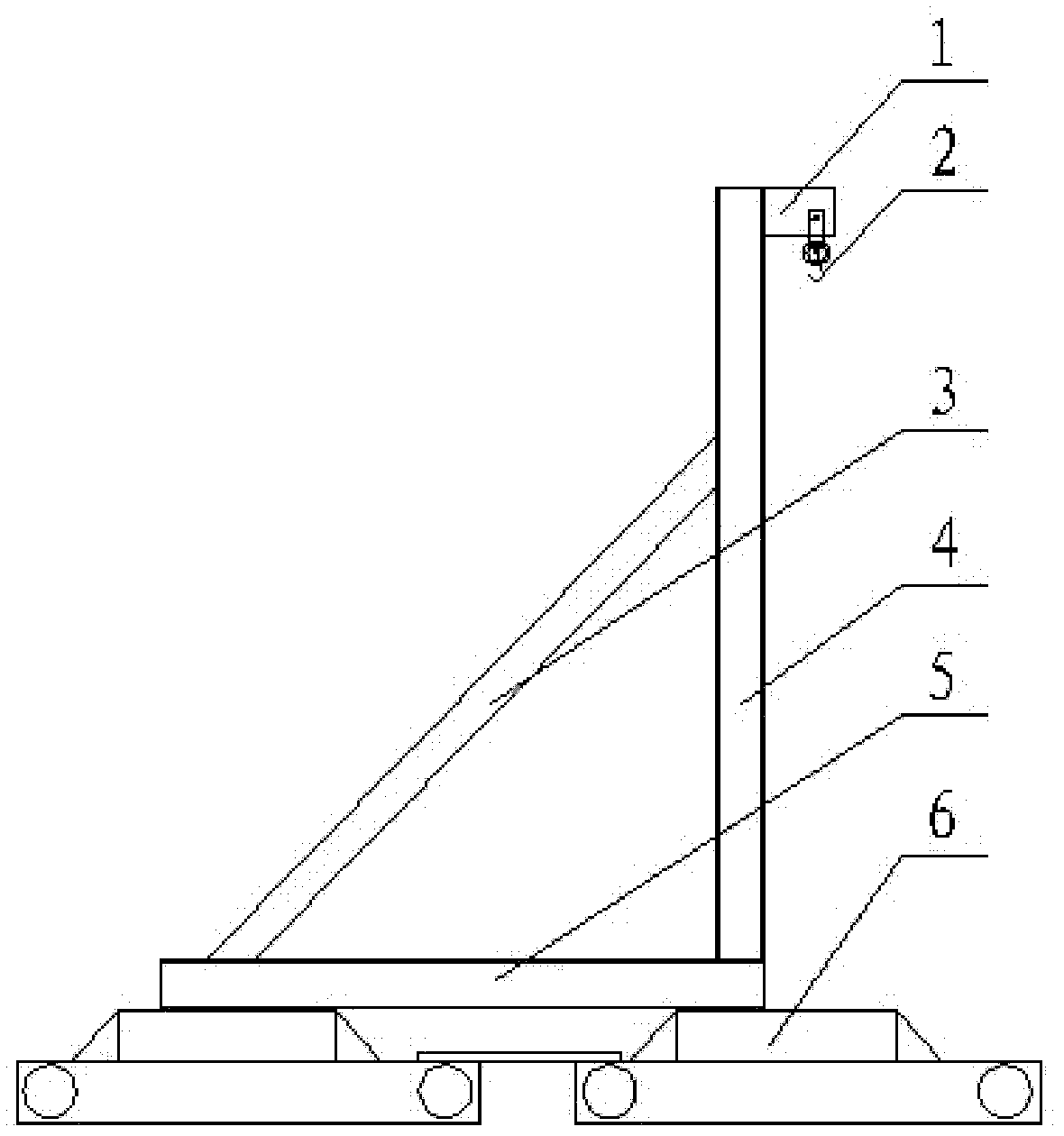

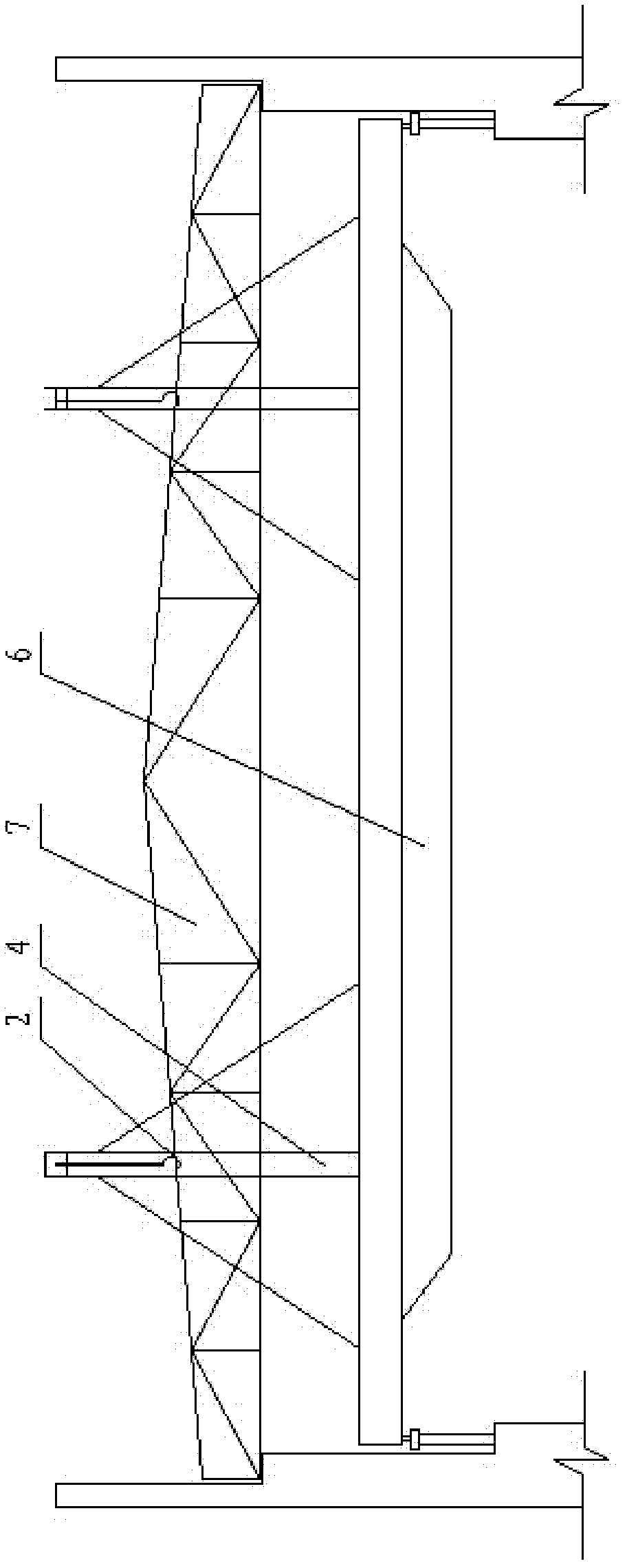

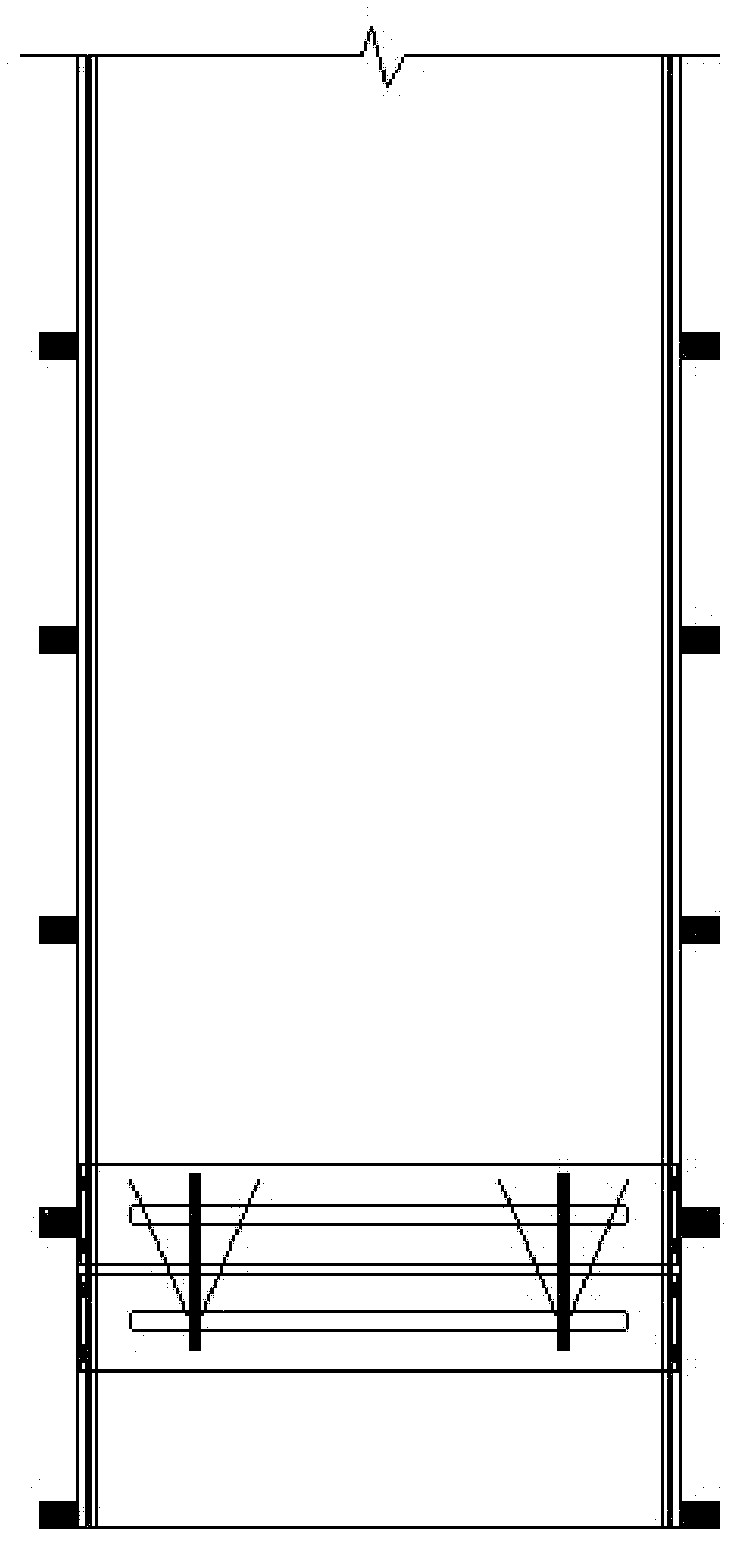

[0027] The special hoisting and hoisting device for the steel roof truss hoisting construction of the main factory building of the power plant includes a beam 5, a vertical beam 4 and a support beam 3, the vertical beam is vertically installed on the beam, the beam is installed on the bridge crane 6, and the support beam is installed obliquely, and The two ends of the support beam are installed on the cross beam and the vertical beam respectively, and the cross beam, the vertical beam and the support beam form a tripod structure.

[0028] A connection beam 1 is installed horizontally on the vertical beam upper end, and a suspension hook 2 is installed on the connection beam, and the suspension hook is used for ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com