Self-heating natural gas hydrate preventing device

A natural gas and thermal technology, used in isolation devices, engines, wind power generation, etc., can solve the problems of wellbore hydrate blockage, insufficient safety and environmental protection, and dangerous operation, and achieve continuous and stable heating, remarkable effect, and convenient operation and management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

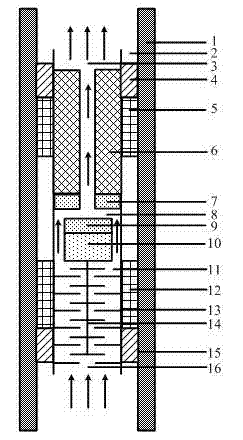

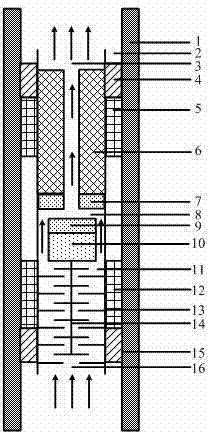

[0014] Taking a self-heating natural gas hydrate prevention and control device for natural gas wells with a daily output of 20,000 cubic meters, which is suitable for 3-1 / 2" oil pipes, as an example, the present invention will be further described in detail. The present invention will be further described in conjunction with the accompanying drawings.

[0015] refer to figure 1 . The self-heating natural gas hydrate control device consists of a power generation system, an electric heating system, and a pipeline internal fixing system. The power generation system consists of an overspeed protection device 9, a generator 10, an impeller 11, a partition 13, a rotating shaft 14, an Composed of ports 16, four impellers 11 are concentrically arranged, separated by partitions 13, and connected to the generator 10 by a rotating shaft 14, and the rotating shaft 14 is also connected to the overspeed protection device 9 to prevent the impellers 11 from rotating too fast during power gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com