Combined floating-type damper brake

A brake pad, floating technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of reducing elastic performance, reducing vehicle weight, increasing manufacturing costs, etc., reducing manufacturing and maintenance costs, and simplifying the replacement operation process. , the effect of reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

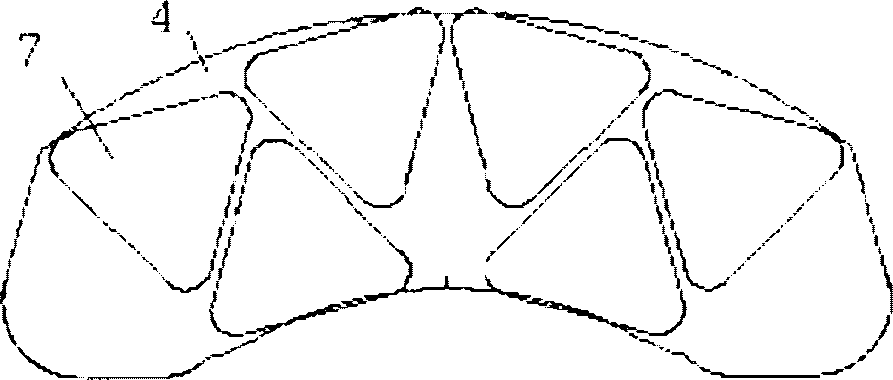

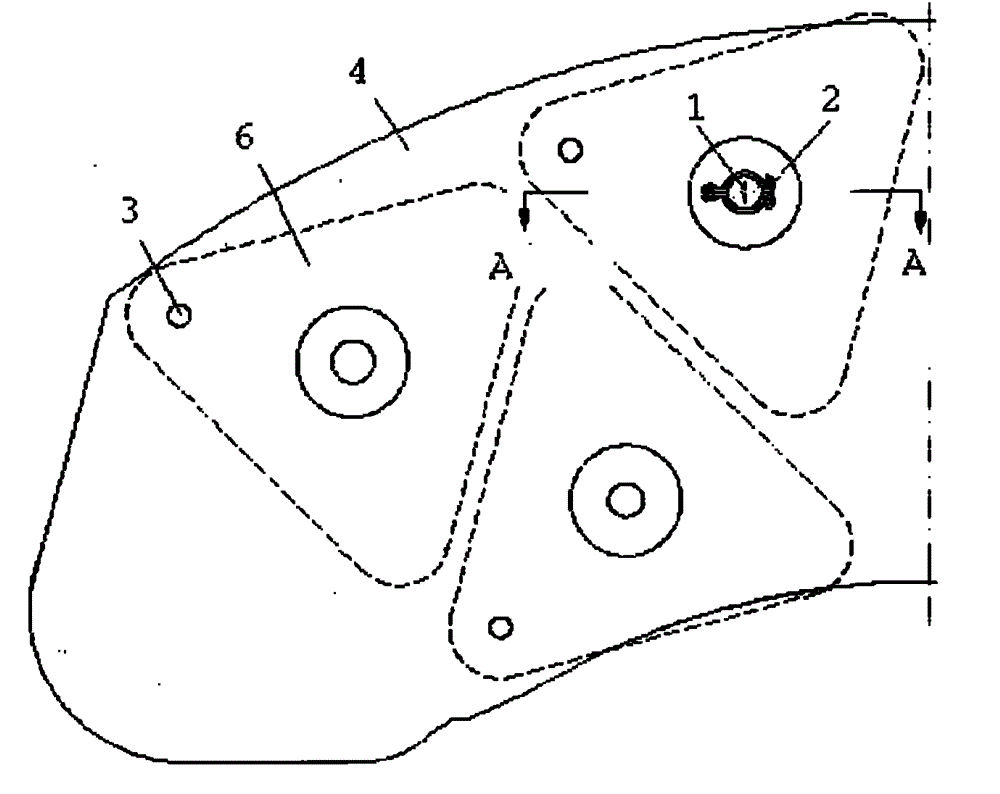

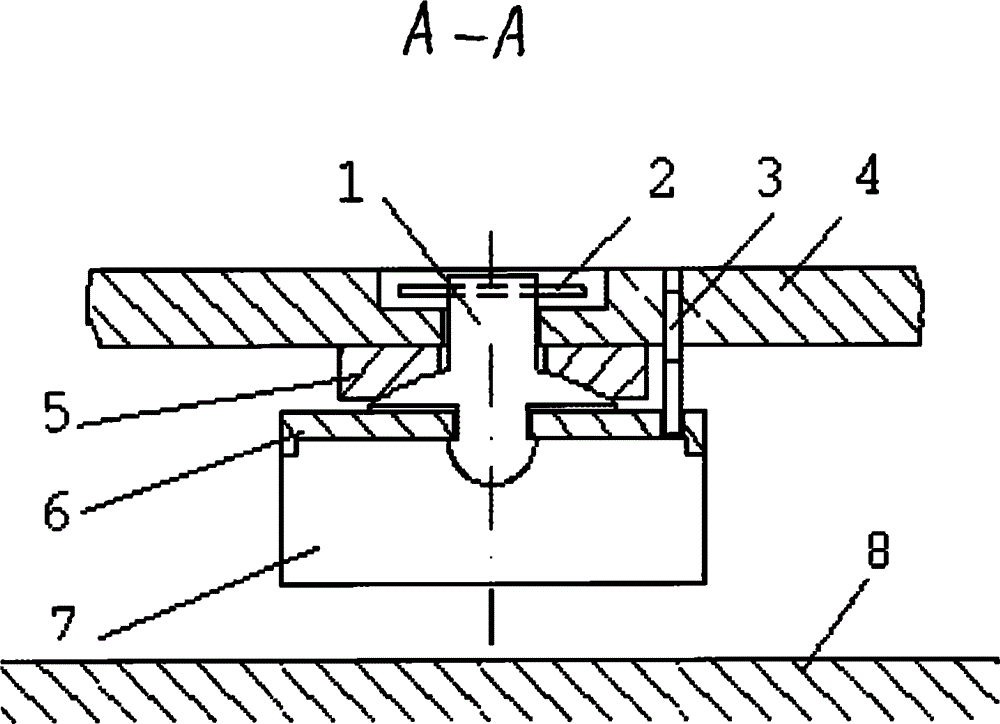

[0018] figure 1 , 2 , 3 and 4 show specific embodiments of the present invention; it is a combined floating brake pad installed on the disc brake of a high-speed train; The brake pads are characterized in that each of the brake pads adopts a combined floating brake pad, and each of the combined floating brake pads is symmetrically arranged and distributed on the supporting plate 4. A floating triangular brake block assembly that rubs against the brake disc 8, each floating triangular brake block assembly is composed of an isosceles triangle brake block 7, a bottom plate 4, a convex seat 1, a concave seat 5, The connecting rod 3 and the pin 2 are composed of an isosceles triangle brake block 7 and the bottom plate 6 are sintered to form an integrated friction block, and the bottom end of the convex seat 1 passes through the bottom plate 6 and is fixed on the bottom plate 6 by riveting; On the convex spherical surface of this convex seat 1, a concave spherical concave seat 5 coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com