Method and device for suppressing chattering of work machine

A suppression device and operating machinery technology, applied in the direction of automatic control devices, feeding devices, computer control, etc., can solve the problems of time-consuming and complicated processes, and achieve the effect of immediate performance improvement, simple operation, and rapid processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

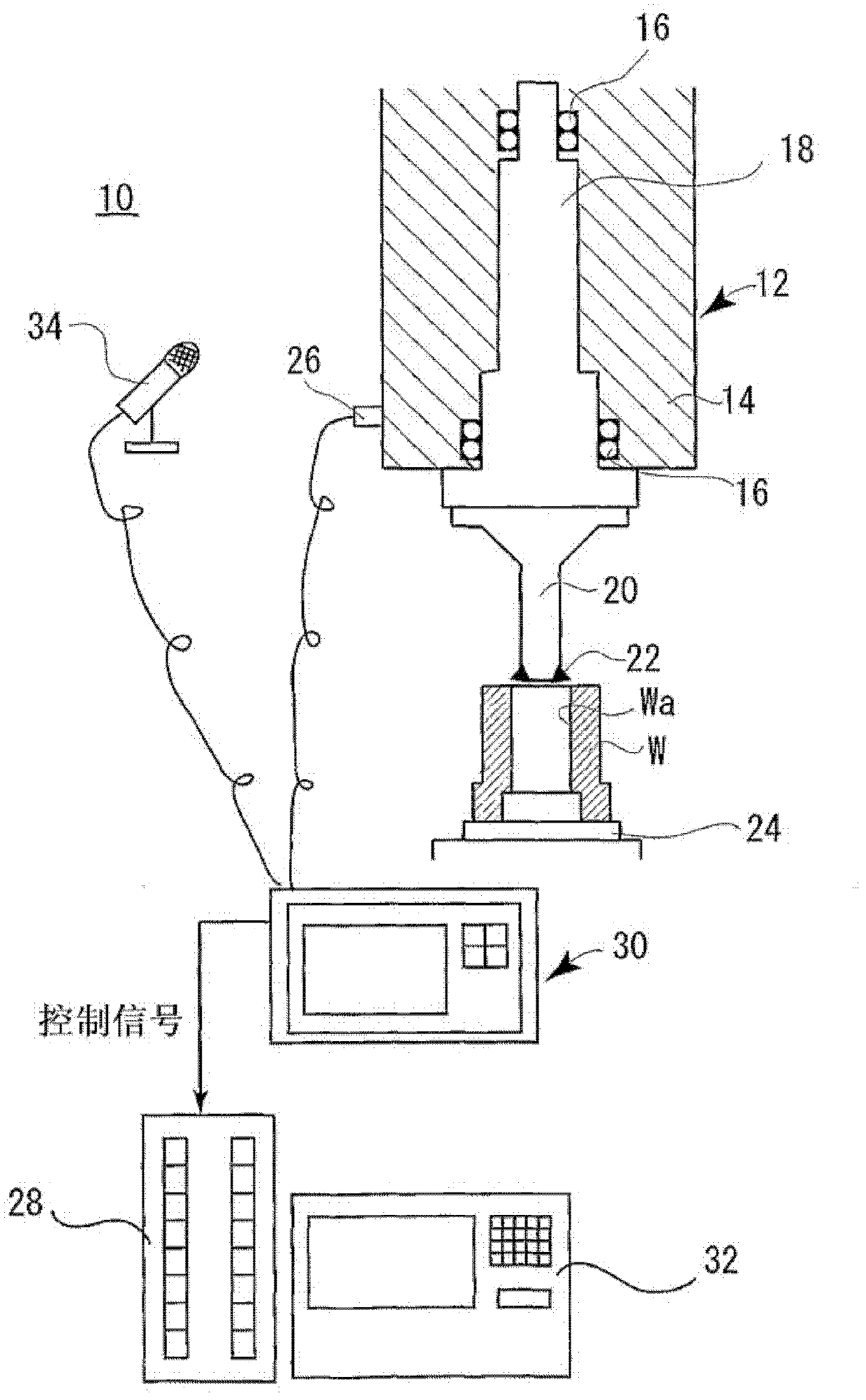

[0028] Such as figure 1 As shown, the chatter suppression device 10 for a working machine according to the first embodiment of the present invention can be applied to a machine tool 12 .

[0029] The machine tool 12 has a rotatable main shaft (spindle) 18 arranged in a casing 14 via a bearing 16, a boring bar (processing tool) 20 detachably attached to the main shaft 18, and a front end of the boring bar 20. Boring cutter 22. A workpiece W is placed on the work table 24 .

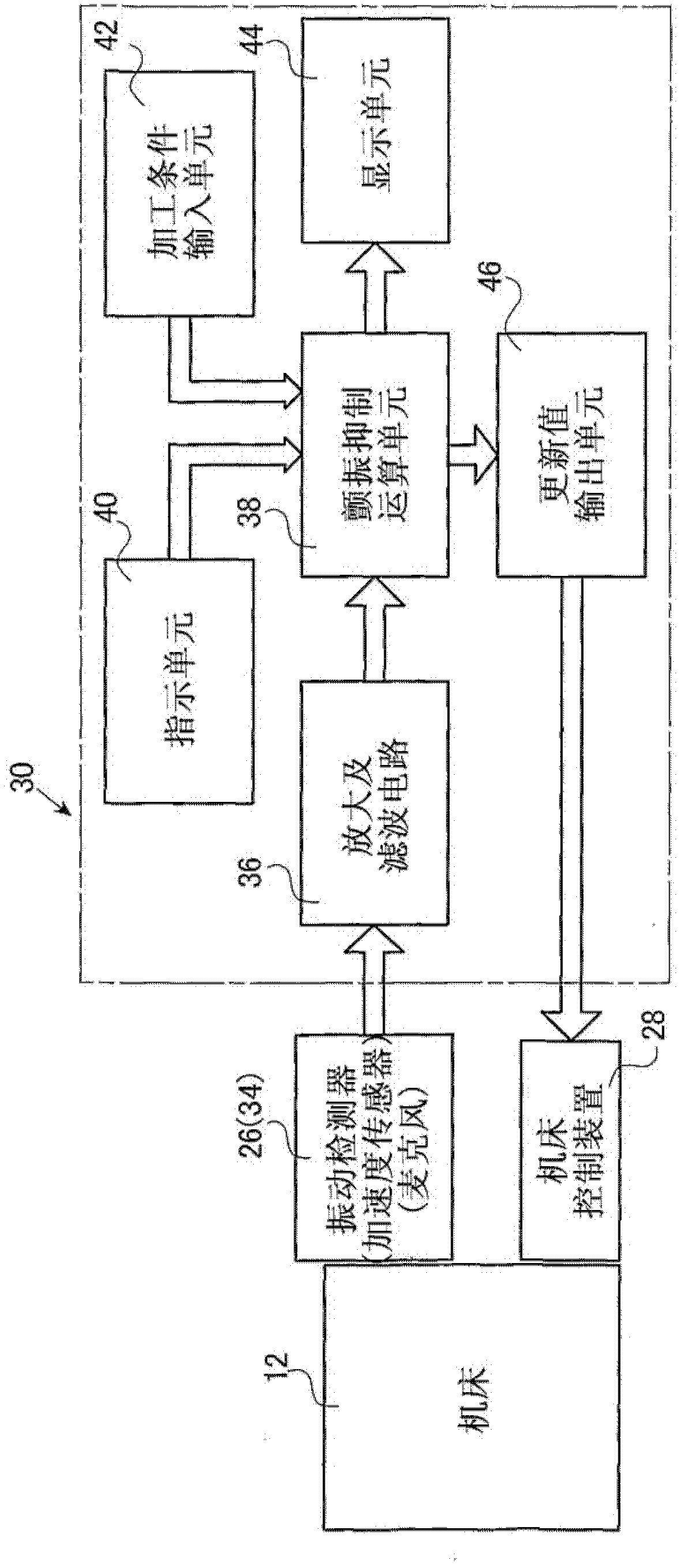

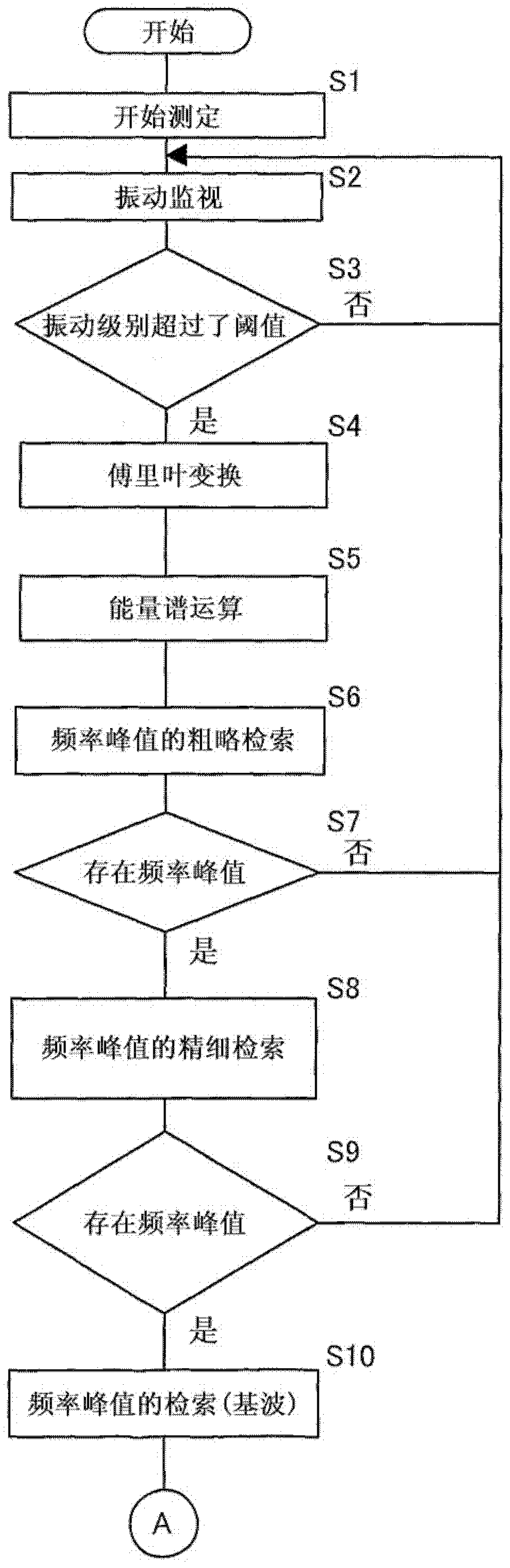

[0030] The chatter suppressing device 10 has an acceleration sensor (vibration detection mechanism) 26 attached to the side of the casing 14 to detect the vibration generated when the boring bar 20 starts to rotate, and analyzes the vibration of the boring bar 20 by Fourier series expansion. The chatter suppression controller 30 that adjusts the rotational speed of the main shaft 18 and outputs an updated value to the machine control device 28 based on the above-mentioned vibration detected when the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com