Spindle unit

A technology for spindles and spindle bearings, applied in the direction of large fixed members, maintenance and safety accessories, drive devices, etc., can solve problems such as spindle unit damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

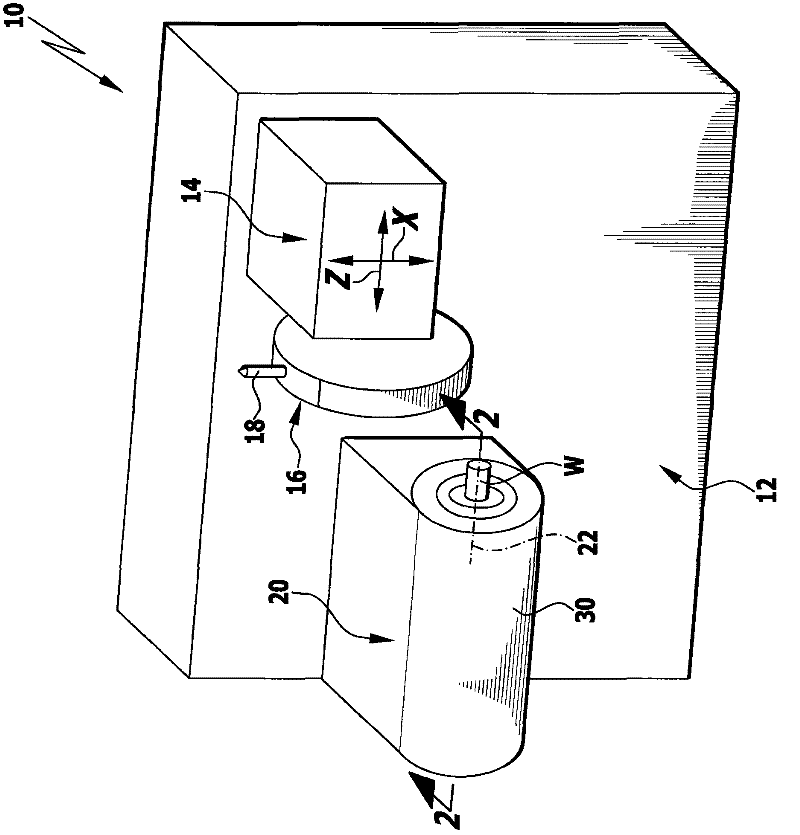

[0055] The machine tool marked with 10 as a whole is in figure 1 The first embodiment shown in includes a frame 12 on which is arranged a tool holder designated as a whole at 14 , which has, for example, a turret head 16 on which a large number of tools 18 can be mounted .

[0056] The turret head 16 is displaceable relative to the machine frame 12 , for example in the direction of the X-axis and in the direction of the Z-axis, in order to be able to process a workpiece W which is mounted rotatably about a spindle axis 22 on a body denoted as a whole by 20 in the spindle unit.

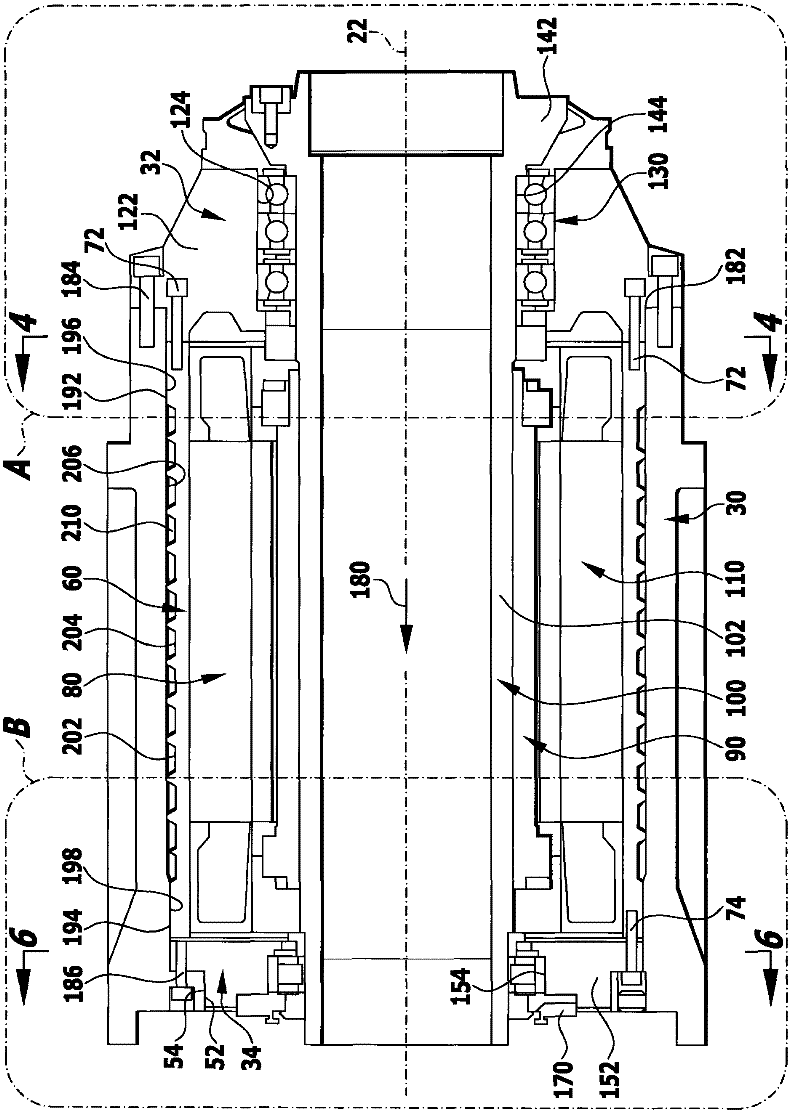

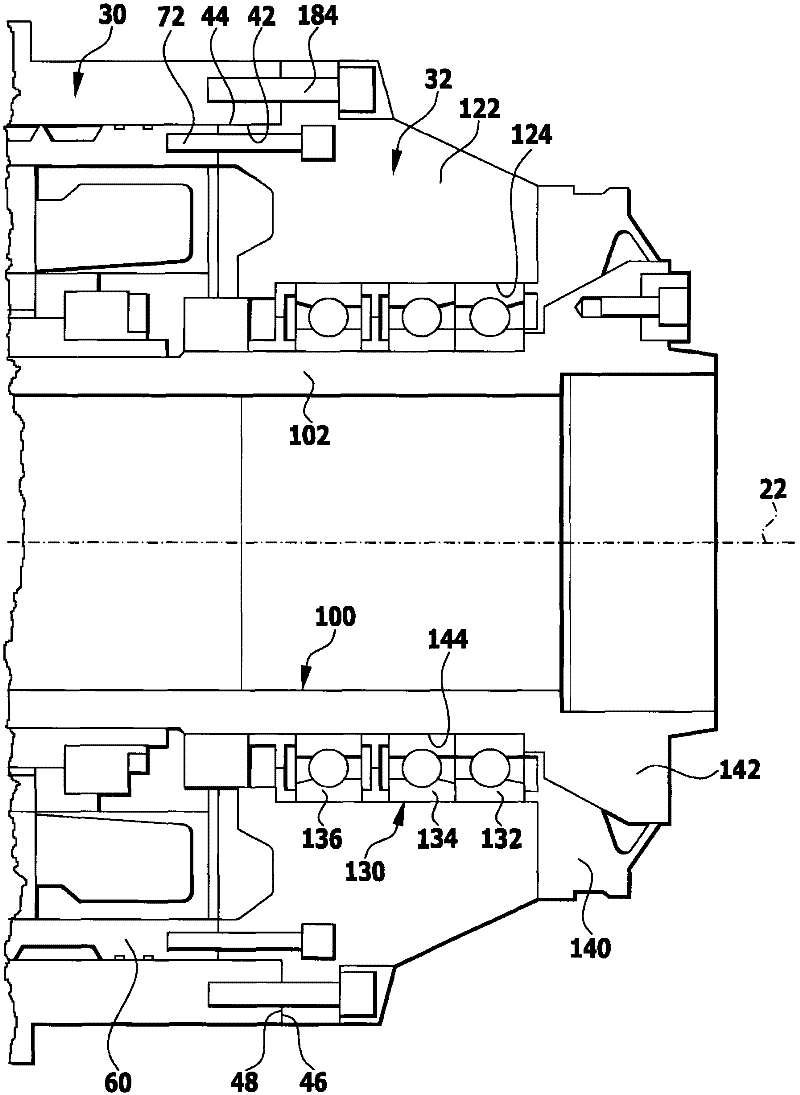

[0057] Such as figure 2 As shown in , the spindle unit 20 comprises a spindle housing 30 which is arranged, for example, firmly or also in a movable manner relative to the frame 12 , but considering the orientation, for example with respect to the X-axis of the machine tool 10 and the Z-axis of the machine tool 10, the spindle housing must be arranged and oriented precisely with reference to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com