Method for testing particle size of nano zirconium dioxide

A technology of nano-zirconia and testing methods, which is applied in particle size analysis, preparation of test samples, measuring devices, etc., can solve the problems of secondary particle size increase, difficulty in powder particle size, poor regularity, etc., and achieve The effect of high accuracy, low usage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

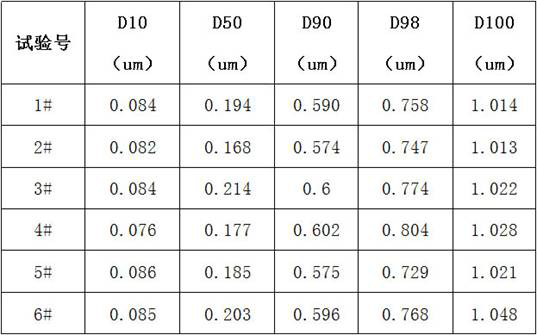

Embodiment 1

[0025] In the present embodiment, the particle size testing method of nanometer zirconia comprises the following steps successively:

[0026] (1) Add 0.1g of nano-zirconia powder to 30g of dilute acetic acid solution (use a beaker to hold the dilute acetic acid solution; the weight of nano-zirconia powder is about 0.33% of the dilute acetic acid solution), and stir evenly (with glass rod to stir evenly) to obtain the first mixed solution;

[0027] In this step (1), the weight percent concentration of dilute acetic acid solution is 0.5%;

[0028] (2) Put the first mixed liquid into the ultrasonic disperser (put the beaker containing the first mixed liquid into the ultrasonic disperser), and ultrasonically disperse the nano-zirconia powder in the first mixed liquid to disperse completely;

[0029] In this step (2), the power of the ultrasonic disperser used is 240W, and the ultrasonic dispersion treatment time is 30min;

[0030] (3) Add an appropriate amount of sodium hexamet...

Embodiment 2

[0037] In the present embodiment, the particle size testing method of nanometer zirconia comprises the following steps successively:

[0038] (1) Add 0.12g of nano-zirconia powder to 30g of dilute acetic acid solution (use a beaker to hold the dilute acetic acid solution; the weight of nano-zirconia powder is 0.4% of the dilute acetic acid solution), and stir evenly (use a glass Stir evenly with the rod), to obtain the first mixed solution;

[0039] In this step (1), the weight percent concentration of dilute acetic acid solution is 0.5%;

[0040] (2) Put the first mixed liquid into the ultrasonic disperser (put the beaker containing the first mixed liquid into the ultrasonic disperser), and ultrasonically disperse the nano-zirconia powder in the first mixed liquid to disperse completely;

[0041] In this step (2), the power of the ultrasonic disperser used is 240W, and the ultrasonic dispersion treatment time is 40min;

[0042] (3) Add an appropriate amount of sodium hexam...

Embodiment 3

[0049] In the present embodiment, the particle size testing method of nanometer zirconia comprises the following steps successively:

[0050] (1) Add 0.15g of nano-zirconia powder to 30g of dilute acetic acid solution (use a beaker to hold the dilute acetic acid solution; the weight of nano-zirconia powder is about 0.5% of the dilute acetic acid solution), and stir evenly (with glass rod to stir evenly) to obtain the first mixed solution;

[0051] In this step (1), the weight percent concentration of dilute acetic acid solution is 0.5%;

[0052] (2) Put the first mixed liquid into the ultrasonic disperser (put the beaker containing the first mixed liquid into the ultrasonic disperser), and ultrasonically disperse the nano-zirconia powder in the first mixed liquid to disperse completely;

[0053] In this step (2), the power of the ultrasonic disperser used is 240W, and the ultrasonic dispersion treatment time is 50min;

[0054] (3) Add an appropriate amount of sodium hexamet...

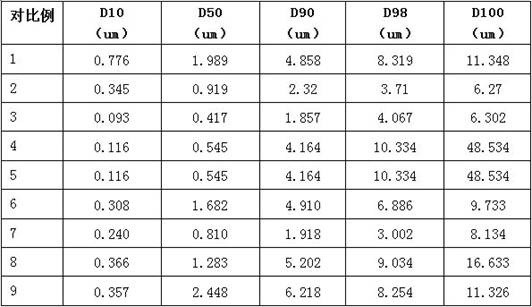

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com