Electronically Commutated Machine, Electronically Slip-Controllable Brake System and Method for Manufacturing an Electronically Commutated Machine

An electronic commutation and electric motor technology, applied to synchronous motors with stationary armatures and rotating magnets, controlling mechanical energy, braking transmissions, etc., can solve problems such as pollution, high cost, and large tolerances of rotor axes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

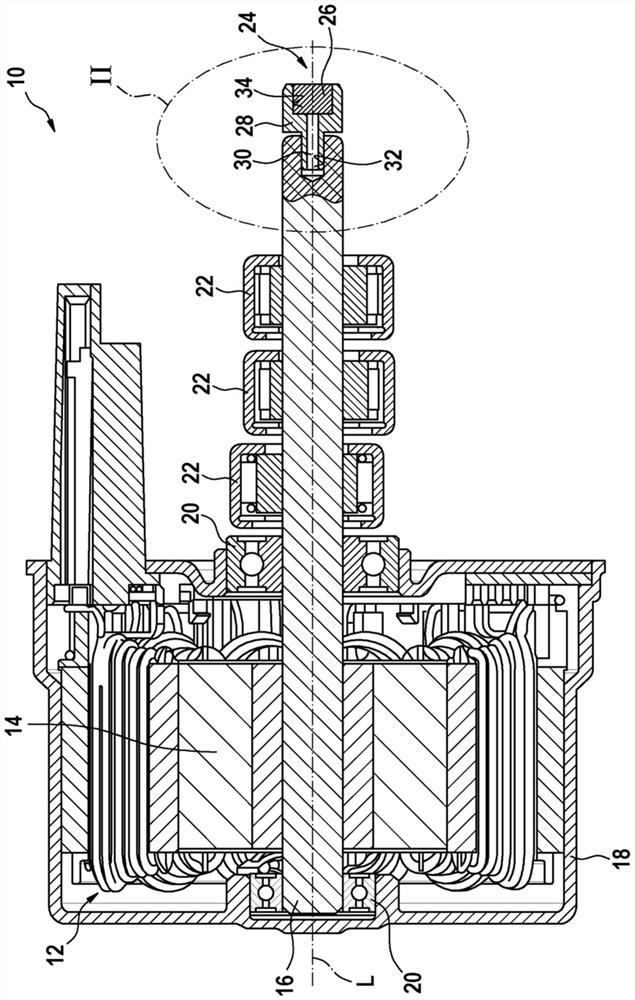

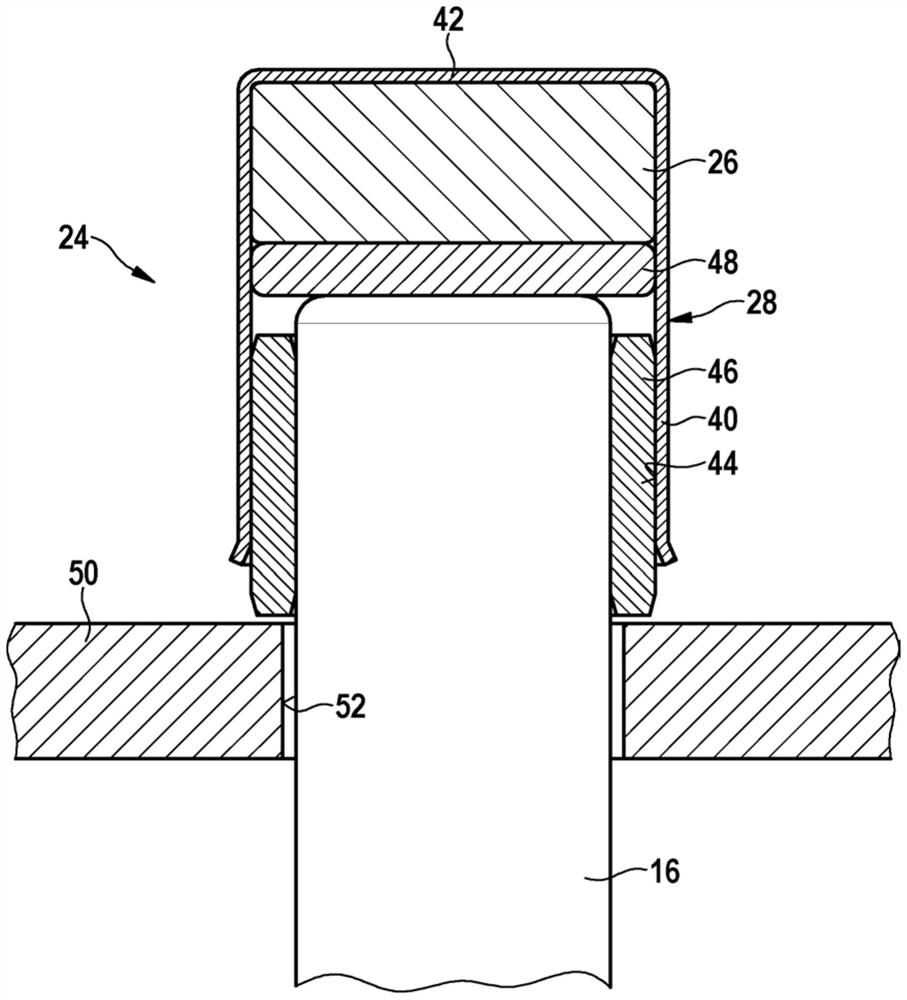

[0027] exist figure 2 The end of the rotor shaft 16 remote from the rotor in an electronically commutated motor is shown in . This end of the rotor shaft 16 carries a signal transmitter 24 . The signal transmitter comprises a magnet element 26 which is arranged in the interior of a holding element 28 and is fastened to the rotor shaft 16 in a rotationally fixed manner by means of the holding element 28 .

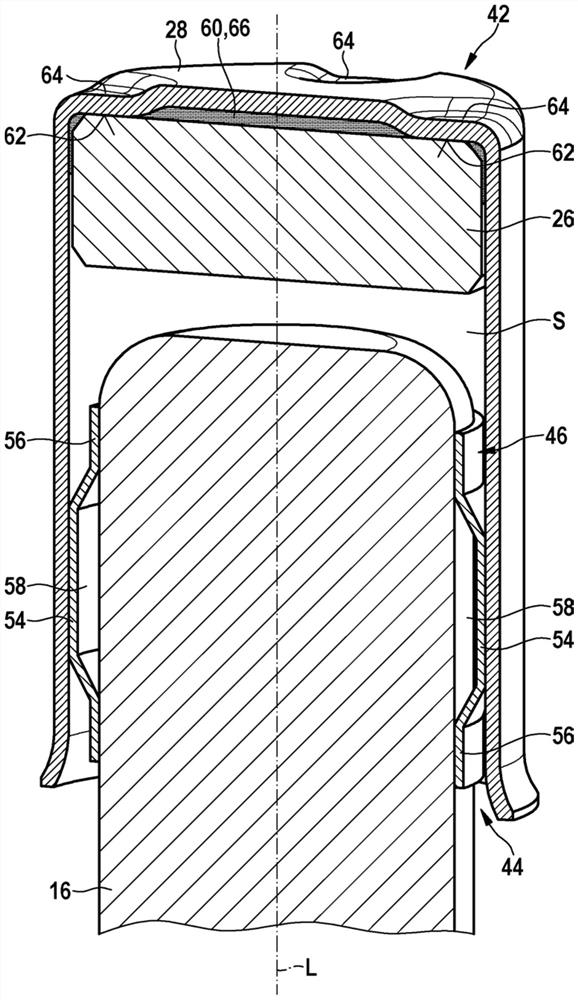

[0028] For this purpose, the holding element 28 is cup-shaped and has a hollow-cylindrical shaft 40 which is closed at its end by a base 42 . The holding element 28 is pushed with its open end onto the rotor shaft 16 such that a section of the rod 40 and a section of the rotor shaft 16 overlap each other. The base 42 also covers the end face of the magnet element 26 facing away from the rotor shaft 16 . The support site for the magnet element 26 can be configured at the bottom 42 so that, if a magnet element is provided, the cross-section of the adhesive gap between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com