LED (light-emitting diode) lamp panel adopting COB (Chip On Board) technology

A technology of LED lamp board and process, which is applied in the direction of electric lamp circuit layout, lighting device, light source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

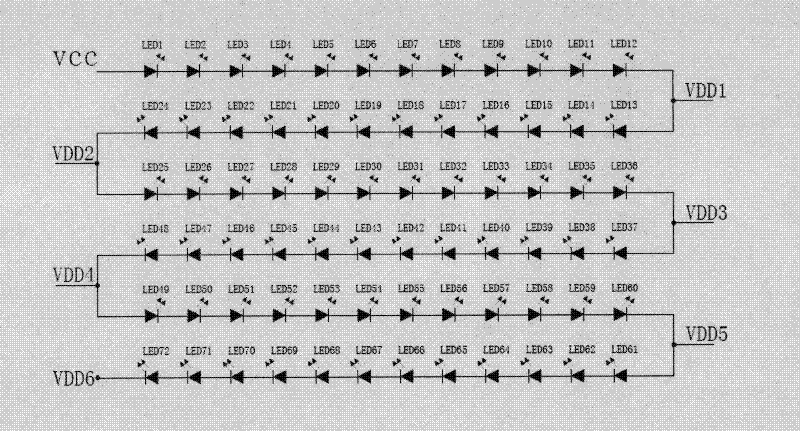

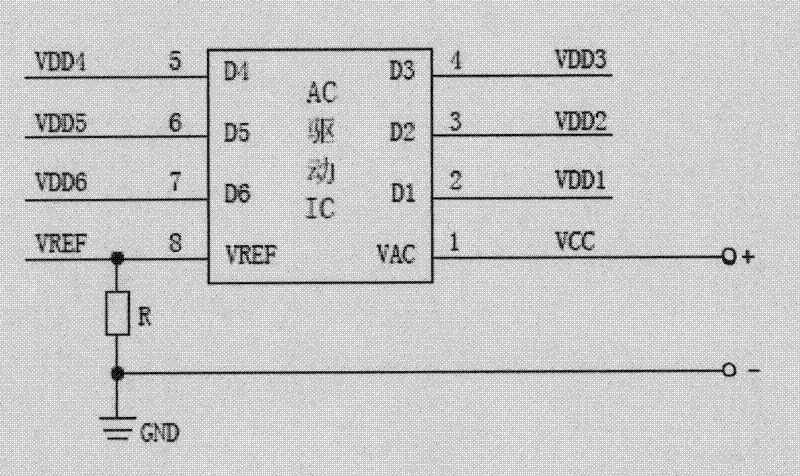

[0017] The present invention is an LED light board adopting COB technology, including a substrate, LED bare chips and AC drive chip bare chips packaged on the substrate by COB technology, please refer to figure 1 , figure 2 As shown, the AC drive chip die is connected to the LED die through a circuit.

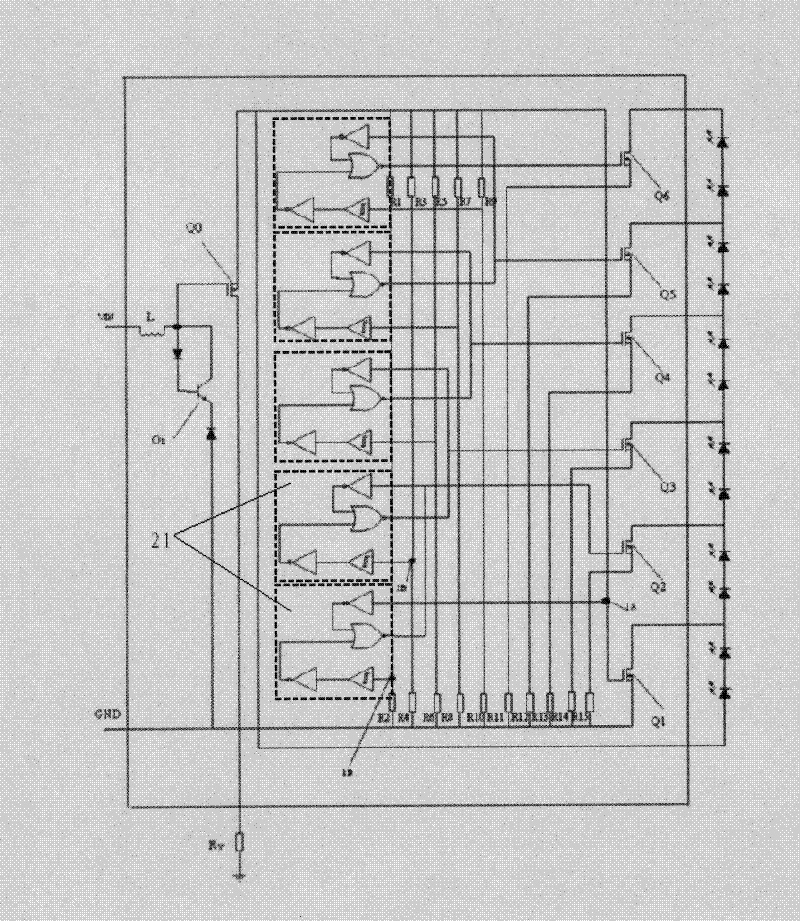

[0018] Please refer to image 3 As shown, the AC drive chip used in the present invention mainly includes a voltage input module, a voltage distribution module, multiple sets of buffer-voltage comparison modules 21 and semiconductor field effect transistors MOSFET Q1-Qn.

[0019] Wherein, the semiconductor field effect transistors MOSFETs Q1-Qn can be V-groove field effect transistors VMOS. The source of MOSFET Q1 is connected to the ground potential, the gate is directly connected to one input terminal of the first group of buffer-voltage comparison modules, and simultaneously connected to the output terminal of the voltage input module, and the other input terminal of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com