Car lift for motor vehicles

A technology of lifting platform and motor vehicle, which is applied in the field of lifting platform, can solve the problems of tilting position of lifting platform, command combination and follow-up combination synchronization interference, etc., and achieve the effect of automatic leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

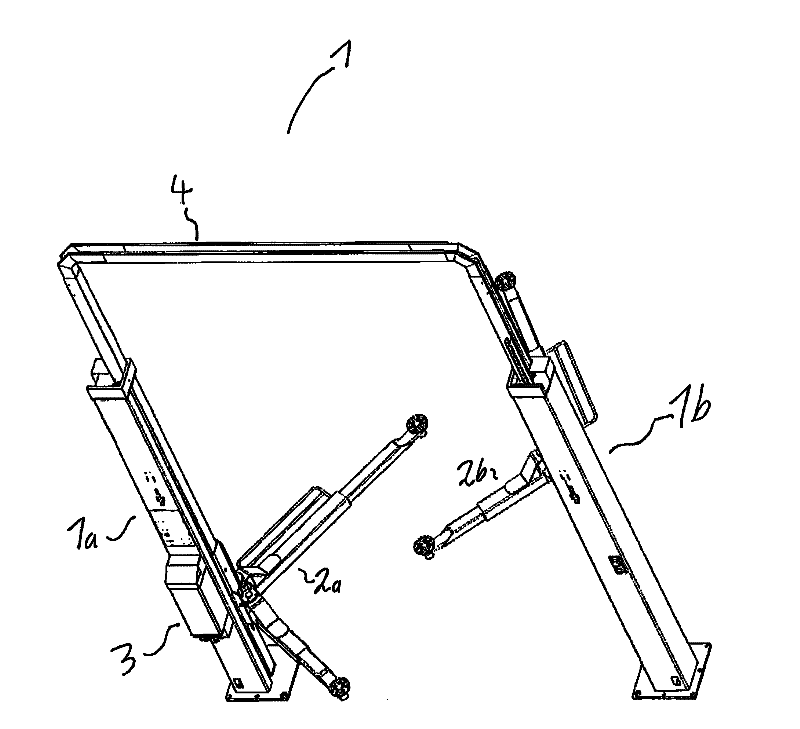

[0040] The lifting platform of the embodiment shown in the figures is configured as a lifting column lifting platform 1 with two lifting elements configured as lifting columns 1a and 1b. Each lifting column has support shears 2a, 2b that can move upwards and downwards, and the support shears act on the motor vehicle arranged between the lifting columns 1a, 1b from below during operation, so that the motor vehicle can follow the support shears 2a and 2b increased and increased.

[0041] The control takes place by means of the unit 3 , which includes an operating panel, not shown, which is operated by an operator.

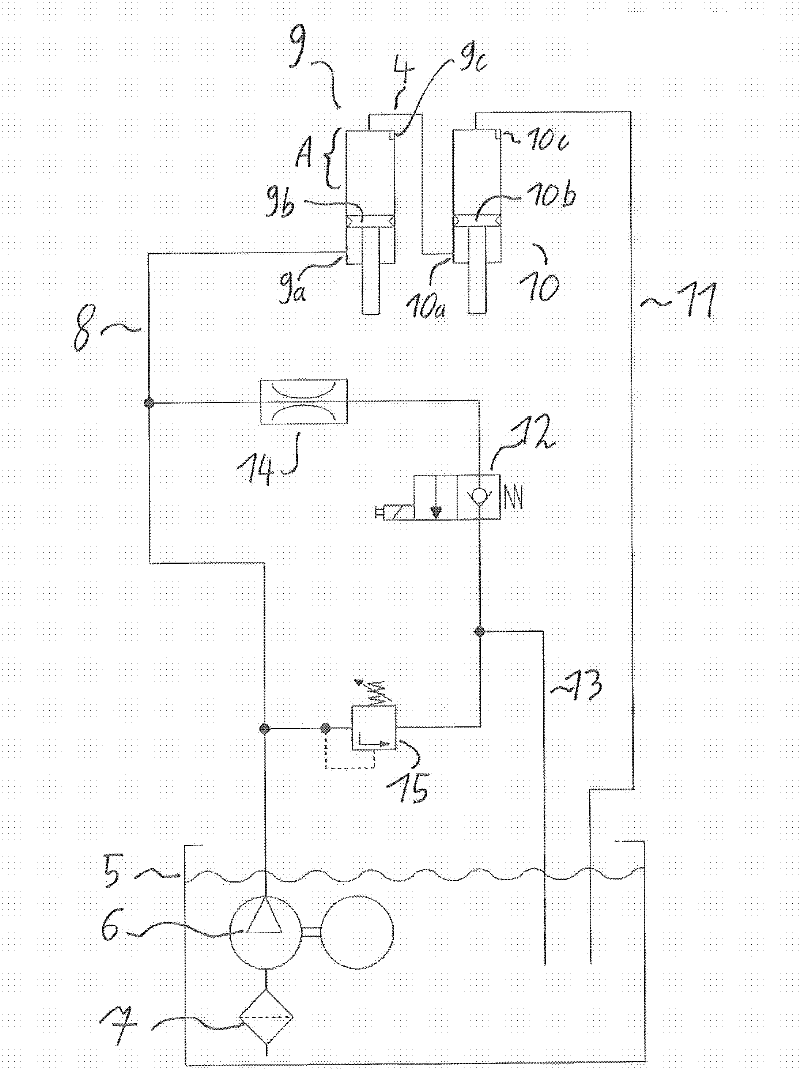

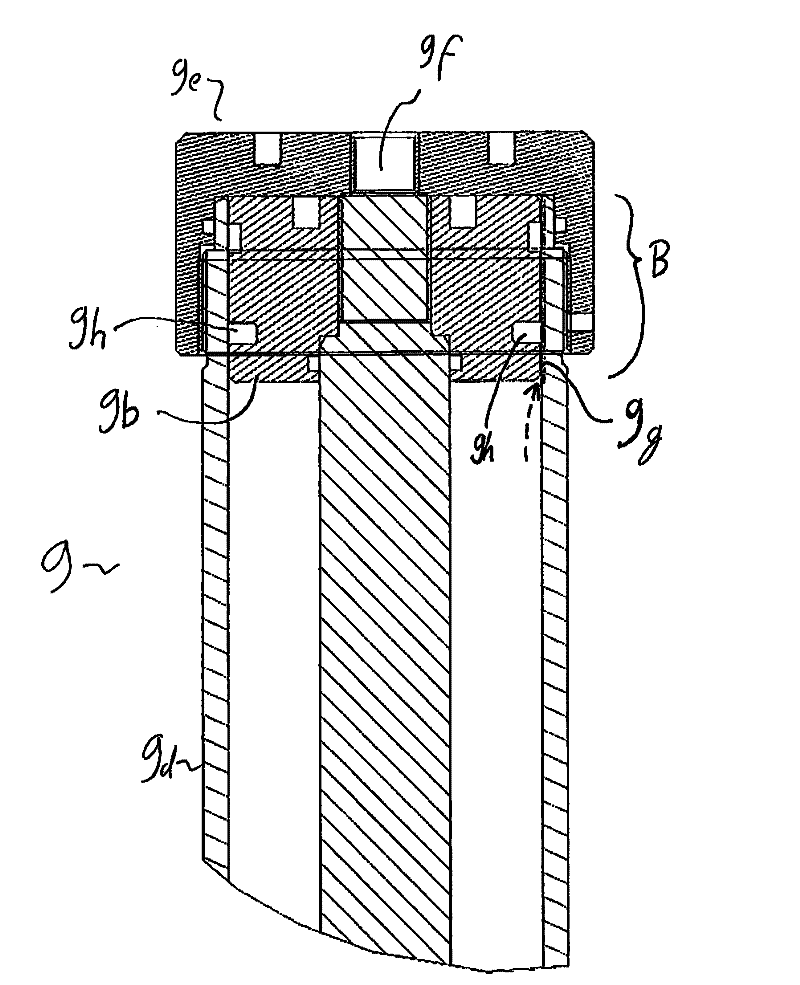

[0042] Lifting column 1a has a first hydraulic cylinder / piston combination for raising and lowering support shears 2a and correspondingly lifting column 1b has a second hydraulic cylinder / piston combination for raising and lowering support shears 2b. The first combination of lifting columns 1 a is designed as a command combination, wherein the overflow opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com