Method for high-efficiency purification of single-wall carbon nanotubes prepared by chemical vapor deposition

A single-wall carbon nanotube, chemical vapor deposition technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problem of purification yield and purity can not be guaranteed at the same time, to ensure purity and yield, easy to expand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 3 mg of single-walled carbon nanotube samples prepared by floating catalyst vapor deposition method (reaction temperature 1000° C., using ferrocene as catalyst, 200 ml / min hydrogen as carrier gas, and 4 ml / min methane as carbon source). , the specifications of single-walled carbon nanotubes are as follows: diameter distribution: 0.8-3.0nm, purity: 30wt%, anti-oxidation temperature: 460°C.

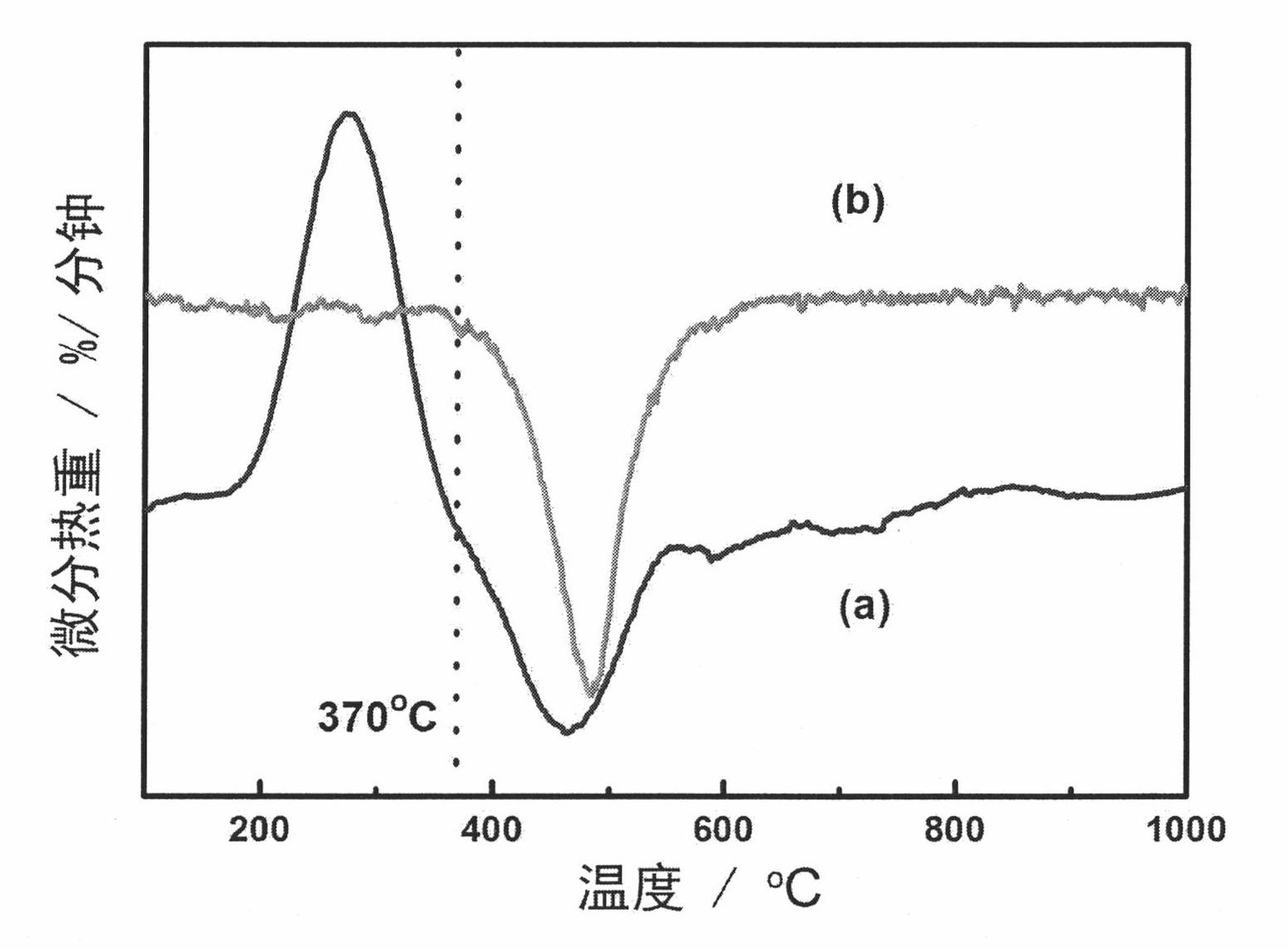

[0026] The thermogravimetric / differential thermal analysis experiment is carried out under the air atmosphere, and the obtained thermogravimetric / differential thermal curve is as follows figure 1 (a) shown. According to the thermogravimetric curve, the concentrated oxidation temperature of amorphous carbon is 350-370°C, and the weight percentages of amorphous carbon, catalyst particles and single-walled carbon nanotubes are 5%, 65% and 30% respectively. 20 mg of the above-mentioned single-walled carbon nanotube sample was evenly placed in a horizontal heating furnace tube with ...

Embodiment 2

[0028] Get the single-walled carbon nanotube sample 1g that utilizes the floating catalyst vapor deposition method of embodiment 1 (reaction temperature 1100 ℃, take ferrocene as catalyst, 200ml / min hydrogen as carrier gas, 4ml / min methane as carbon source), Evenly place it in a horizontal heating furnace tube with an inner diameter of 45mm and a constant temperature zone length of 10cm, pass in 1000ml / min of air, and oxidize at 370°C for 20h. After the sample was cooled to room temperature, it was taken out and soaked in hydrochloric acid solution (concentration: 20wt%) and washed at 80°C for several times until the hydrochloric acid solution no longer changed color. Wash the sample with deionized water until the pH is 7, dry the sample in vacuum at 120° C. for 5 hours, take it out after cooling, and weigh it. The weight of the sample is 0.28 g. Take 3 mg of the purified single-walled carbon nanotube sample, and carry out the thermogravimetric / differential thermal analysis ex...

Embodiment 3

[0030] 3 mg of purchased single-walled carbon nanotubes prepared by the Hipco method. In this embodiment, the specifications of the single-walled carbon nanotubes are as follows: the diameter distribution is 0.6-1.3nm, the purity is 95wt%, and the oxidation resistance temperature is 500°C.

[0031] Carry out thermogravimetric / differential thermal analysis experiment under air atmosphere, according to this thermogravimetric curve qualitatively draw the temperature that the concentrated oxidation of amorphous carbon is 350 ℃, wherein the weight percent of amorphous carbon and single-walled carbon nanotube is 2%, respectively. 95%, and the rest are catalyst particles accounting for 3%. Put 50 mg of the above-mentioned single-walled carbon nanotube sample evenly in a horizontal heating furnace tube with an inner diameter of 22 mm and a constant temperature zone length of 4 cm, pass air at 100 ml / min, and oxidize at 325 ° C for 10 h. After the sample was cooled to room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap