Niobium-titanium composite micro-alloyed hotrolled deformed bar and production method thereof

A hot-rolled ribbed steel bar and micro-alloying technology, which is applied in the field of micro-alloyed construction steel, can solve the problems of affecting corporate profits, high prices of ferro-vanadium and ferro-niobium, and increasing production costs, so as to improve the product market. Competitiveness, increasing production technology routes, and increasing profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The chemical composition of molten steel is: C: 0.21%; Si: 0.41%; Mn: 1.27%; Ti: 0.015%; Nb: 0.018%; P: 0.015%;

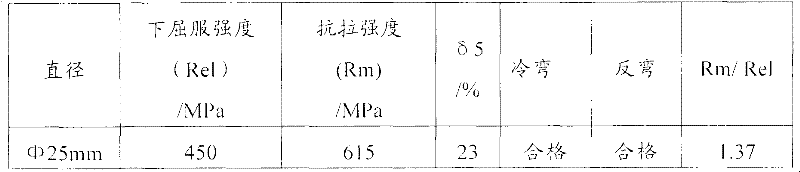

[0024] The production process is: converter smelting, argon blowing, continuous casting, and rolling processes. In the converter smelting process, ferro-niobium and ferro-titanium alloys are used for microalloying. 0.13wt%, using barium-based deoxidation, the addition of barium-based is 1.10kg / t steel, and evenly added in alignment with the steel flow during the steel laying process. In the later stage of adding, join the ladle steel flow impact zone with the steel flow; argon blowing process: strong blowing first and then weak blowing, the total time is 12 minutes; the average temperature of the tundish is controlled at 1520°C during the continuous casting process, and the average casting speed is 2.9m / min . , the process parameters of the rolling process are: heating temperature 1150-1200°C, starting rolling temperature controlled at 1030-1100°C, finishin...

Embodiment 2

[0030] The chemical composition of molten steel is: C: 0.17%; Si: 0.52%; Mn: 1.30%; Ti: 0.030%; Nb: 0.023%; P: 0.012%;

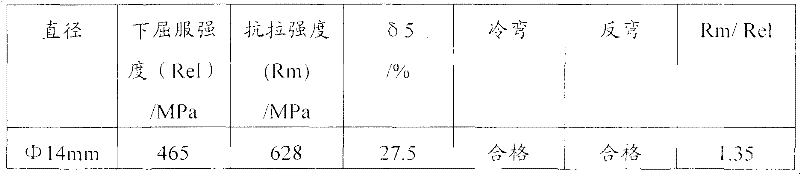

[0031] The production process is: converter smelting, argon blowing, continuous casting, and rolling processes. In the converter smelting process, ferro-niobium and ferro-titanium alloys are used for microalloying. It is 0.12wt%, using barium-based deoxidation, the amount of barium-based deoxidation is 0.95g / t steel, and it is added evenly in alignment with the steel flow during the steel laying process. In the later stage of adding, join the steel flow impact zone of the ladle with the steel flow; argon blowing process: strong blowing first and then weak blowing, the total time is 11 minutes; the average temperature of the tundish is controlled at 1525°C during the continuous casting process, and the average casting speed is 2.75m / min . , the technical parameters of the rolling process are: heating temperature 1150-1200°C, starting rolling temperature cont...

Embodiment 3

[0036] The chemical composition of molten steel is: C: 0.23%; Si: 0.47%; Mn: 1.30%; Ti: 0.024%; Nb: 0.020%; P: 0.025%;

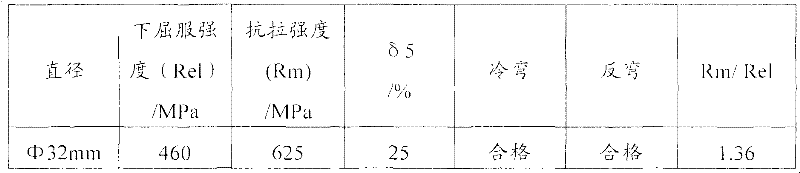

[0037] The production process is: converter smelting, argon blowing, continuous casting, and rolling processes, wherein, in the converter smelting process, ferro-niobium and ferro-titanium alloys are used for microalloying, and high-stretch supplementary blowing is used in the smelting process to control the end point [C] It is 0.14wt%, using barium series deoxidation, the addition amount of barium series is 1.26kg / t steel, and it is added evenly in alignment with the steel flow during the steel laying process. In the later stage of adding, join the steel flow impact zone of the ladle with the steel flow; argon blowing process: strong blowing first and then weak blowing, the total time is 14 minutes; the average temperature of the tundish is controlled at 1518°C during the continuous casting process, and the average casting speed is 3.05m / min . The technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com