Elastic support sheet

A technology of elastic support and pawl support, applied in the direction of brake types, brake components, mechanical equipment, etc., can solve problems such as unfavorable brake pad adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described with reference to the drawings.

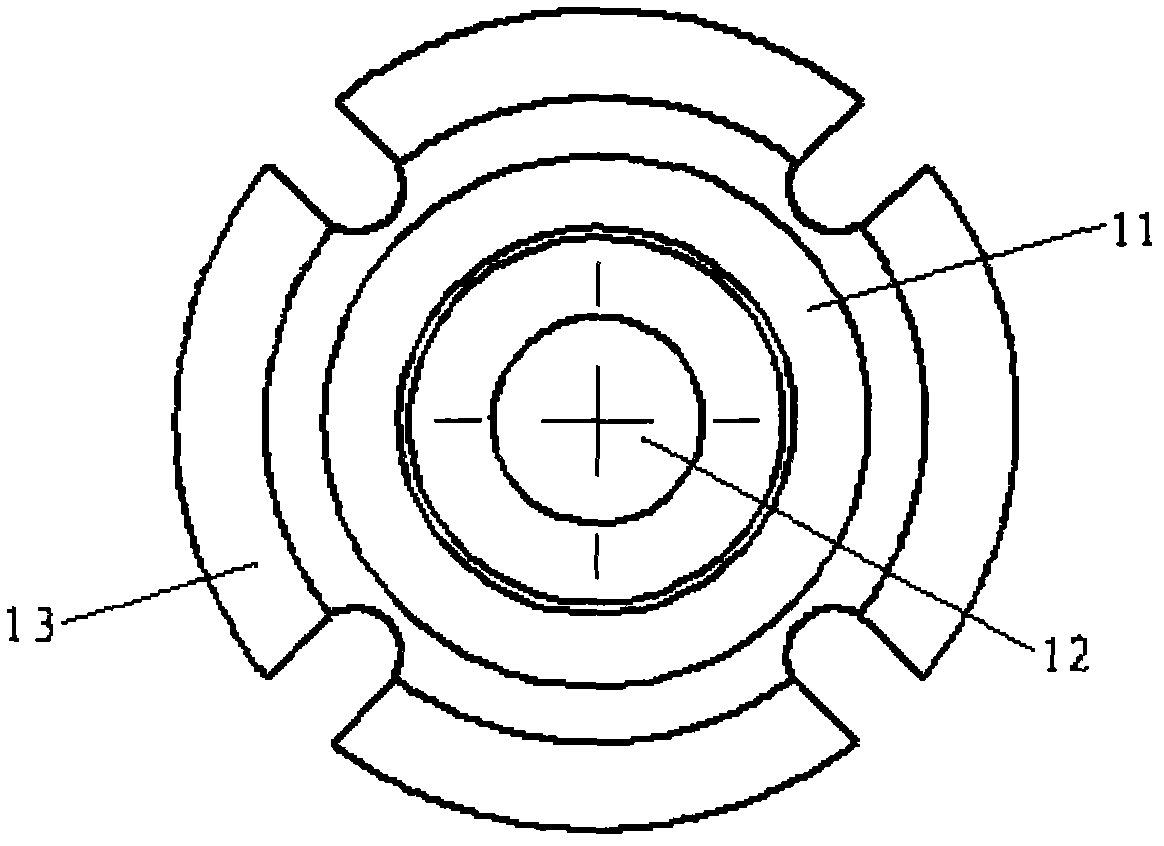

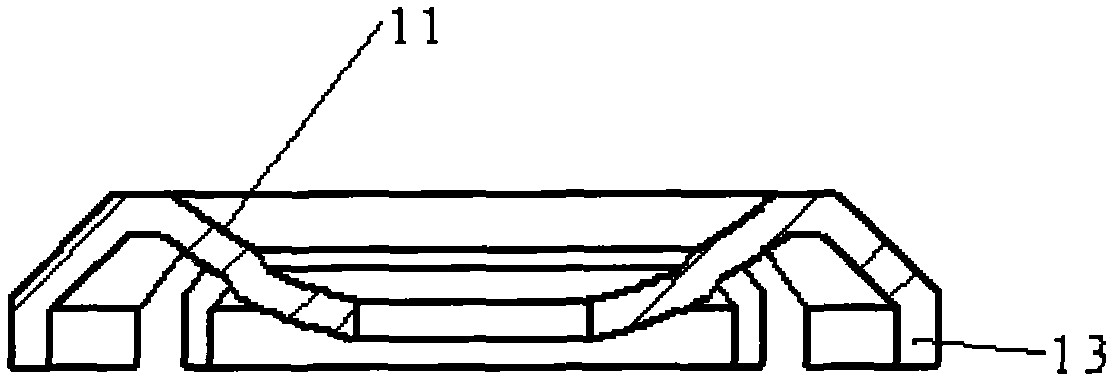

[0013] The elastic support sheet of the present invention comprises a spherical support surface part (11), a central guide hole part (12), and a fixed support ratchet part (13).

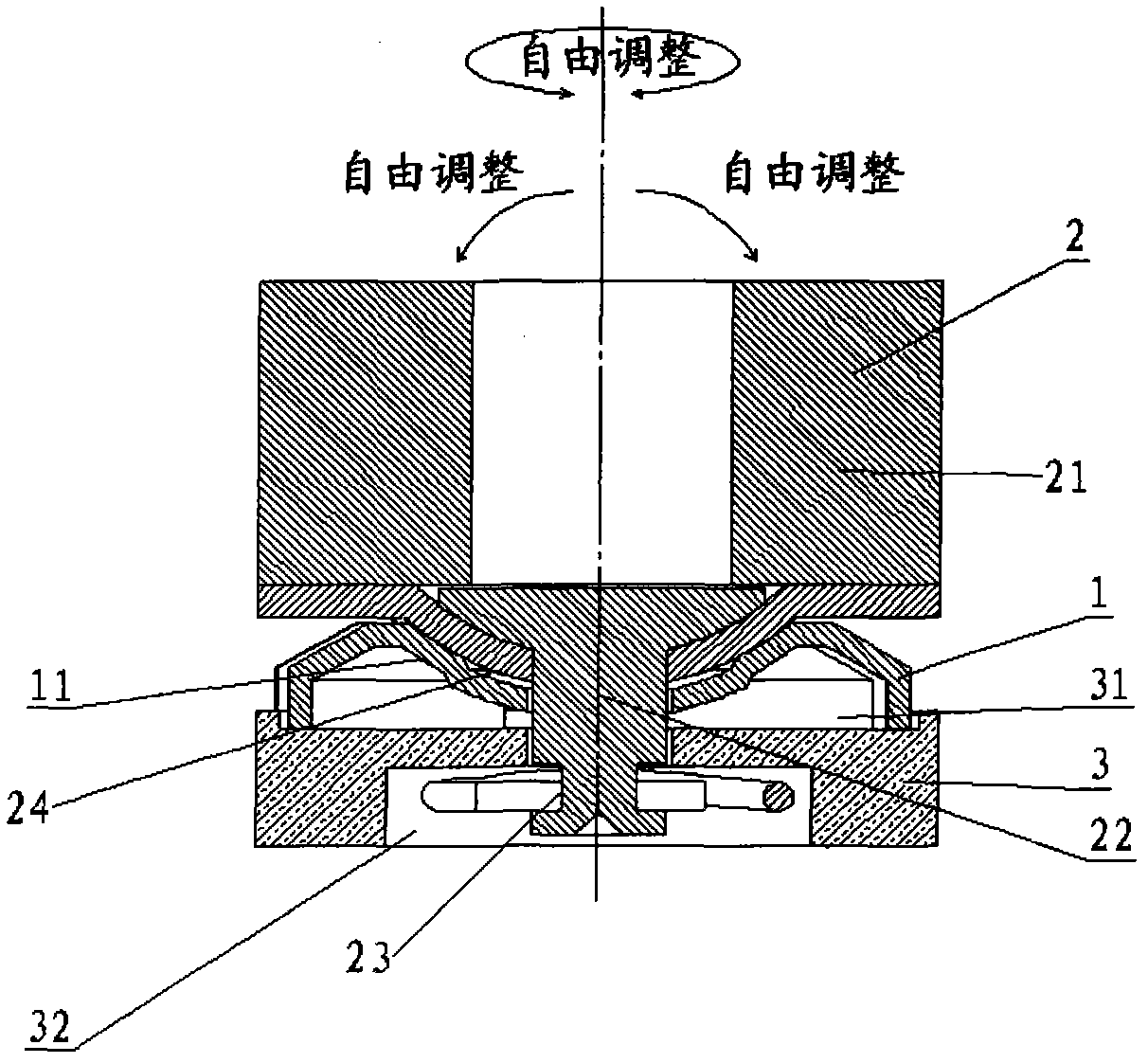

[0014] The amount of elastic deformation of the elastic support sheet of the present invention depends on the forming process and heat treatment process of the high temperature resistant stainless spring steel material.

[0015] Depend on image 3 A cross-sectional view of the floating structure of a single friction block is given. There are multiple friction blocks (2) on the back plate (3) of the brake pad to connect the positioning holes (33), and the positive plate of the back plate has multiple spot-faced holes for the support plate. (31), there are a plurality of spring clips spot facing holes (32) on the back side of the backboard. The fixed support pawl (13) of the elastic support piece (1) is placed in the spot-fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com