Temperature sensitive drum for temperature control valve

A technology of temperature control valve and temperature sensing cylinder, which is applied in valve details, valve device, valve operation/release device, etc., can solve problems such as low production efficiency, damaged temperature sensing cylinder, poor welding, etc. Long service life and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

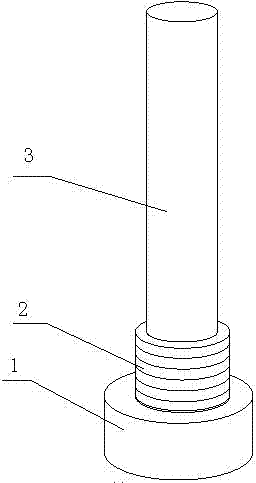

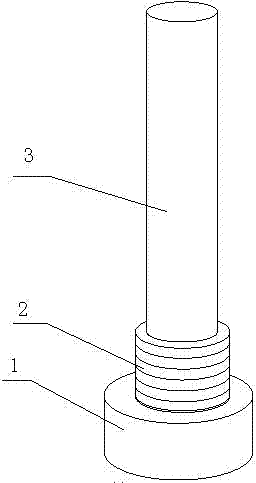

[0013] In this embodiment, the end of the copper pipe is connected to the end of the connecting part 2, and the copper pipe 3 and the base 1 are integrally formed by one-time casting, so that the connection between them is stable, and the stability of the connection between the copper pipe 3 and the base 1 is increased. , to avoid post pickling operations and the impact of acid on the environment.

[0014] Both the above-mentioned copper pipe and the base are made of copper material, and are formed by one-time casting through a mold. The process is simple and the production efficiency is greatly improved.

[0015] The present invention integrally forms the copper tube 3 with the base 1 and the connecting part 2, which increases the stability of the connection between the copper tube 3 and the base 1, and at the same time avoids the complicated operation process in the prior art and avoids the pollution of the environment by pickling. It has the advantages of simple operation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com