Vacuum collector tube

A vacuum collector tube, vacuum degree technology, applied in heating devices, solar thermal devices, solar thermal power generation and other directions, can solve the problems of low heat exchange efficiency, inability to quickly increase the thermosiphon head, etc., to reduce consumption and improve heat exchange. Efficiency, material reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

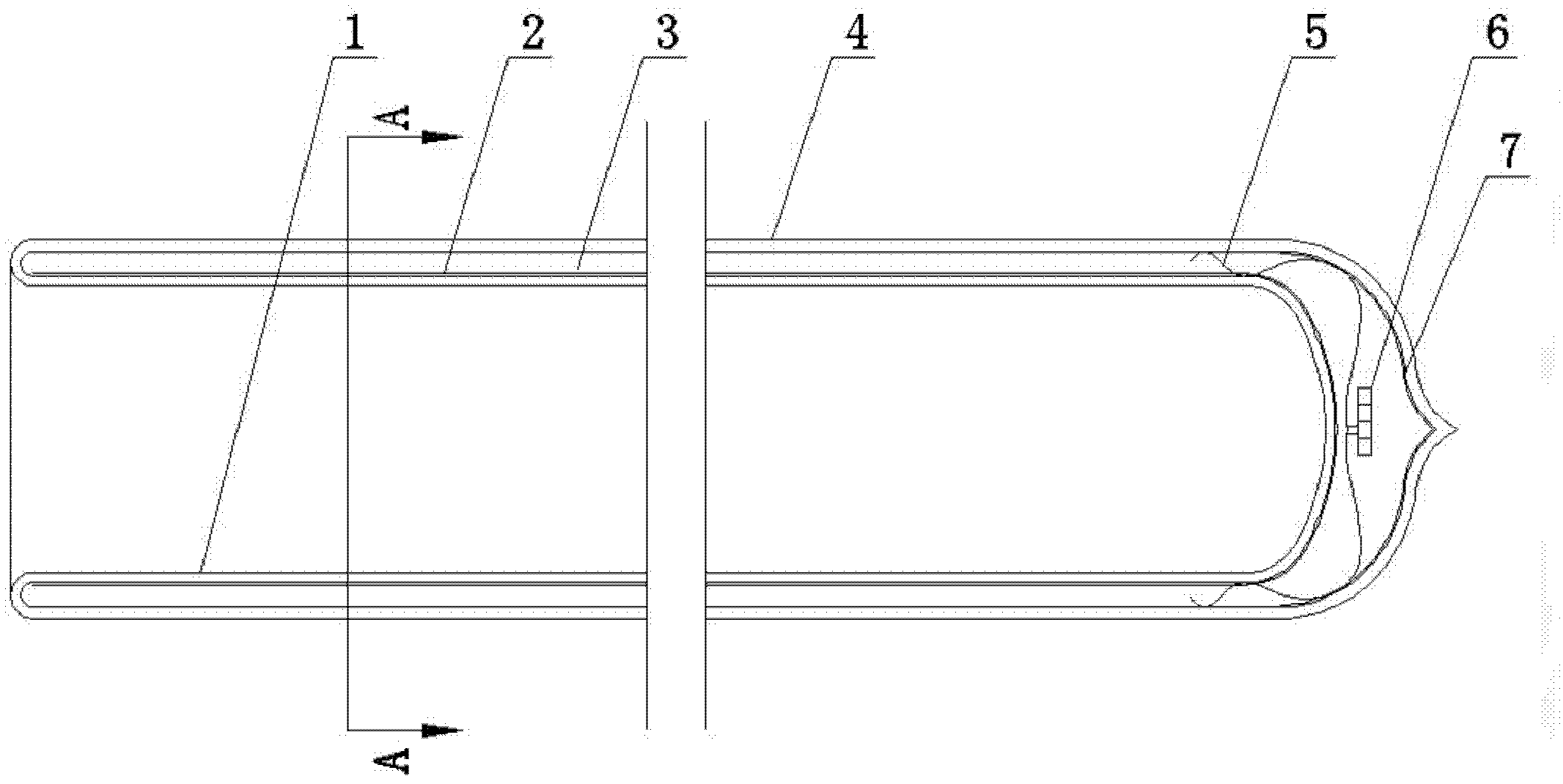

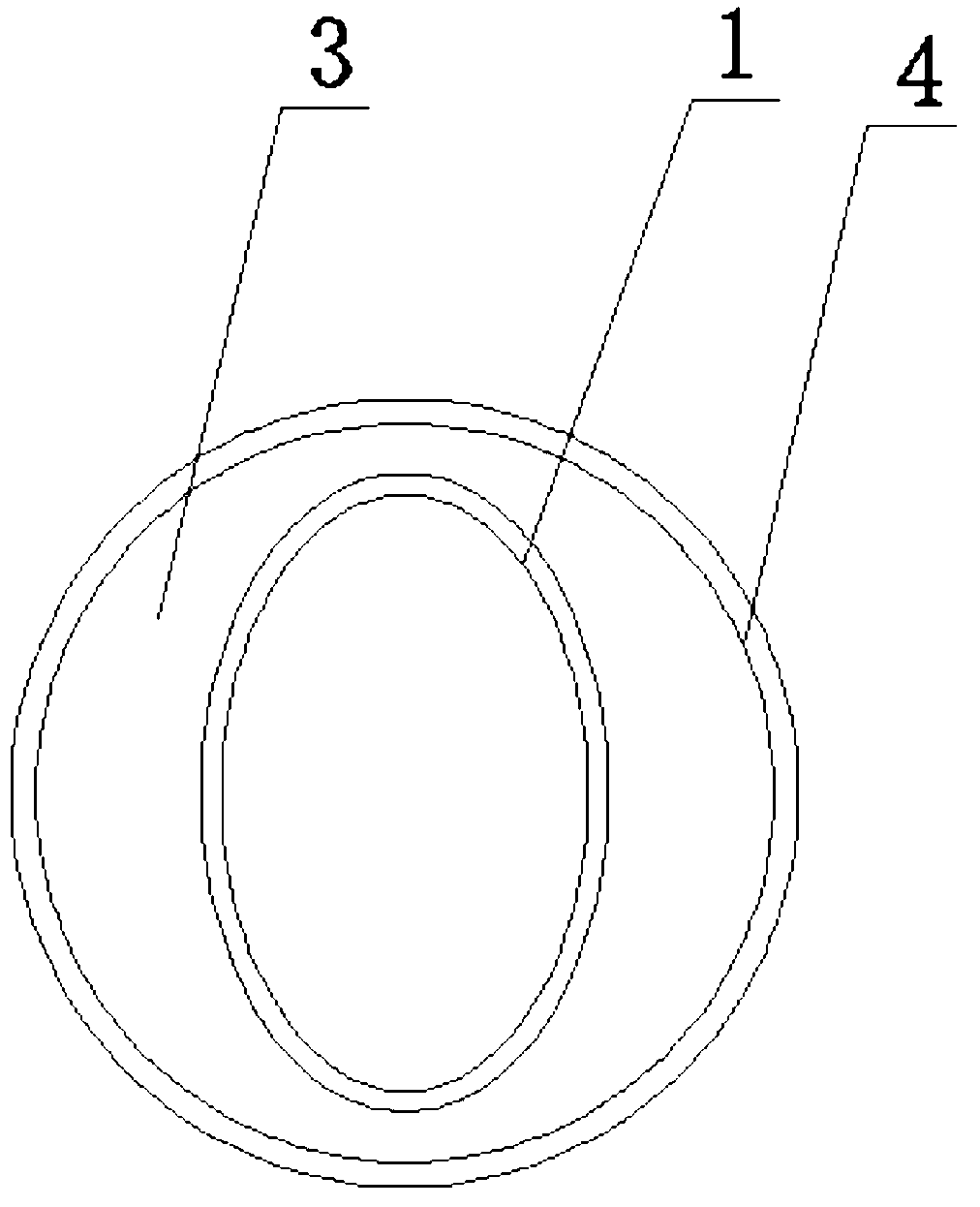

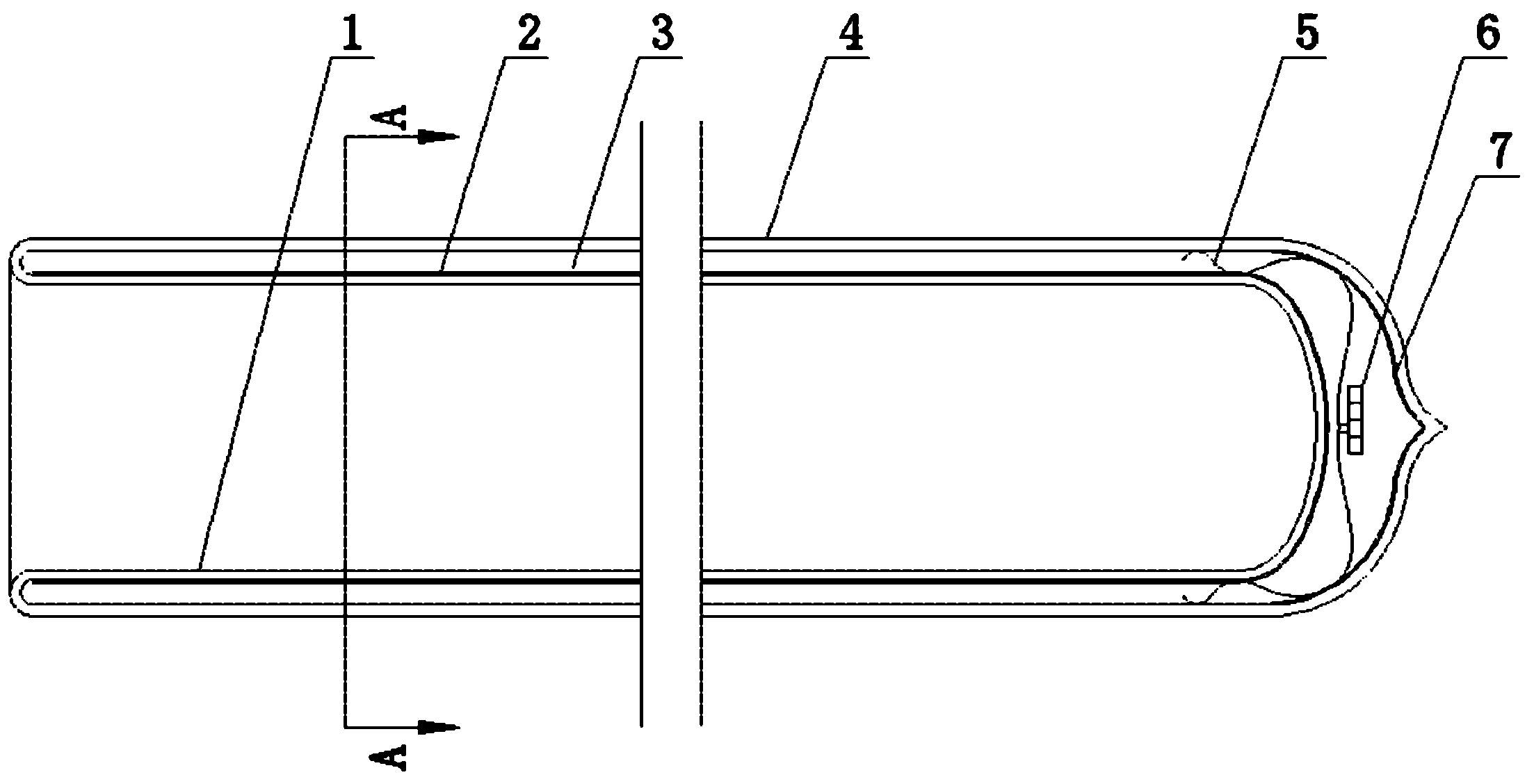

[0012] Referring to the attached picture:

[0013] The vacuum heat collecting tube of the present invention comprises an oval inner glass tube 1 and a circular cover glass tube 4, the oval inner glass tube 1 is sealed with a round bottom, and the surface of the oval inner glass tube 1 is coated with a sun selective Absorbent coating 2, the opening end of the oval inner glass tube 1 is sealed with the opening end of the cover glass tube 4, the round bottom of the oval inner glass tube 1 is provided with a spring support frame 5 and the inner wall tension of the cover glass tube 4 Tightly fixed, there is a vacuum interlayer 3 between the oval inner glass tube 1 and the cover glass tube 4, and there is a getter 6 to maintain the vacuum degree of the vacuum interlayer 3.

[0014] The short axis of the cross-section of the oval inner glass tube 1 faces the sunlight. Generally, the direction of the short axis is set according to the direction of the strongest sunlight at noon. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com