TUFR composite winding wire for track traction transformer

A traction transformer, composite winding technology, applied in the direction of transformer/inductor coil/winding/connection, metal/alloy conductor, bendable conductor, etc., can solve the problems of high cost, dependence on imports, etc. Package structure, the effect of reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

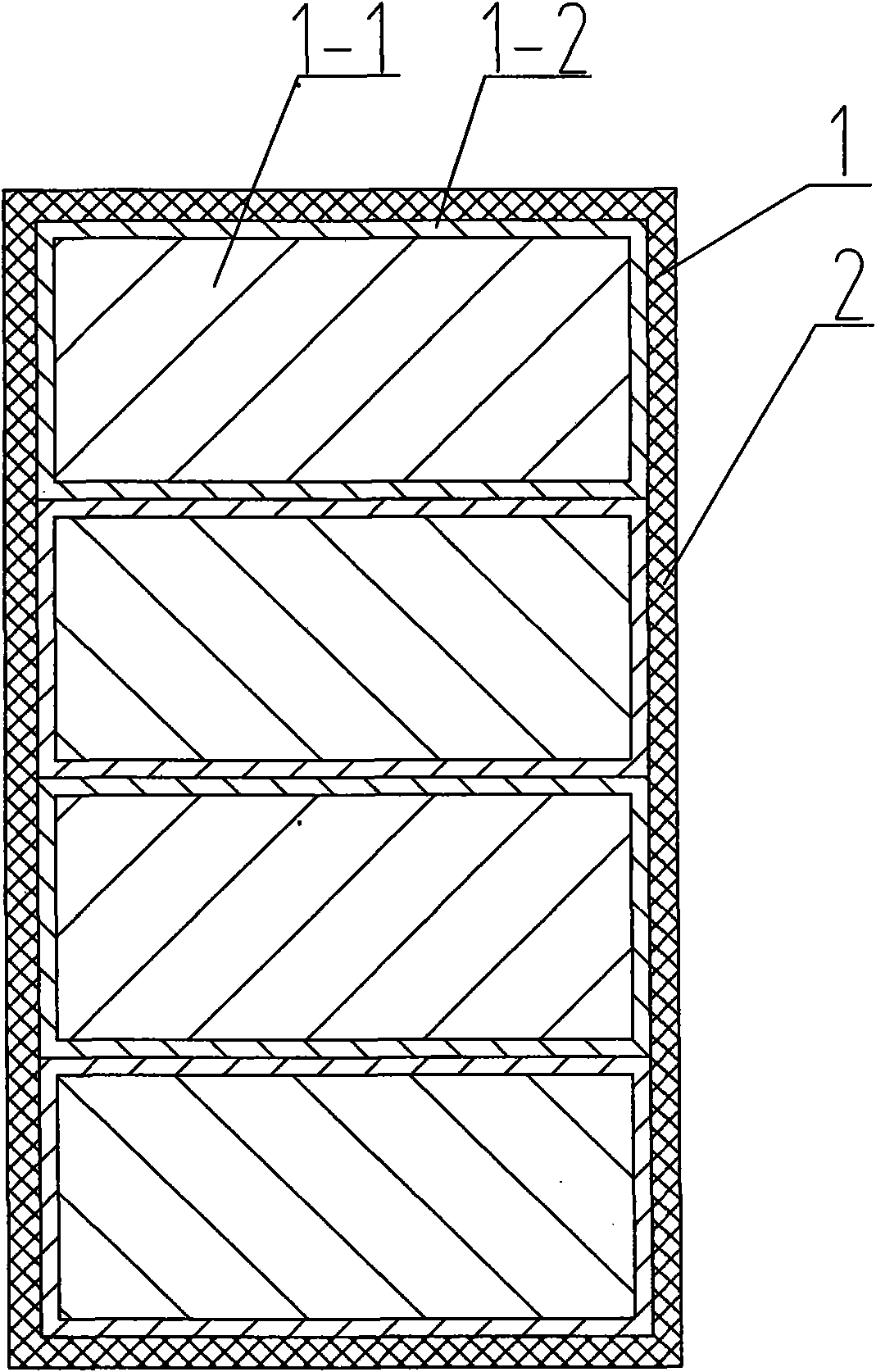

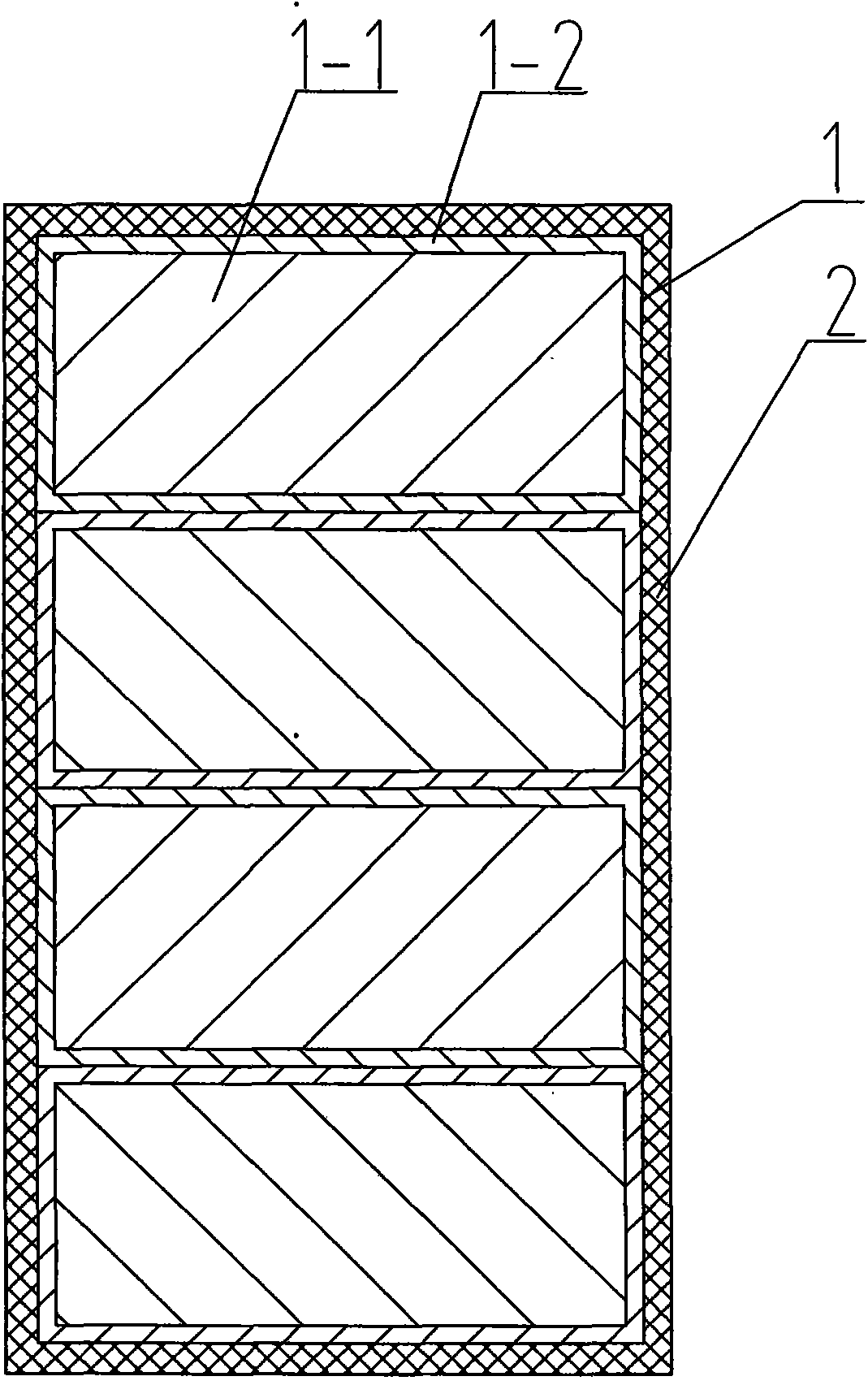

[0008] Such as figure 1 As shown, the present invention includes at least two (four in this example) composite insulated wires 1, each composite insulated wire 1 is composed of an aluminum core 1-1 and an aromatic polyamide insulating layer 1-2, and the aromatic polyamide The insulating layer 1-2 is wrapped around the corresponding aluminum core 1-1.

[0009] Aromatic polyamide insulated overall wrapping layer 2 is arranged outside four composite insulated wires 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com