Double-side plastic packaging method of LGA (Land Grid Array)

A technology for plastic sealing molds and packages, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as poor contact of packages, affecting product yield, and open circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings, but those of ordinary skill in the art should understand that these embodiments are provided so that this disclosure will be thorough and complete and not intended to limit the scope of the present invention. The embodiments shown in the drawings are merely exemplary, and the invention should not be construed as being limited to these examples. In the drawings, the size and relative sizes of layers and regions are exaggerated for clarity.

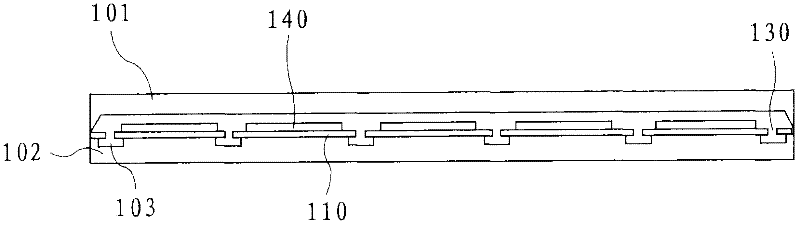

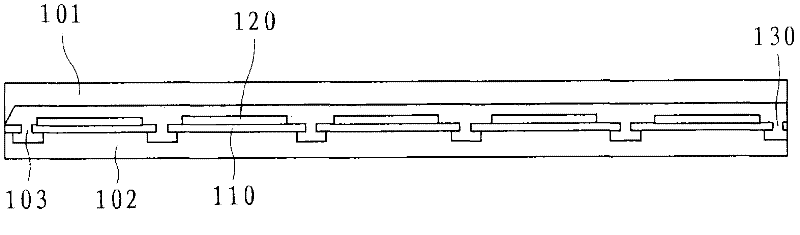

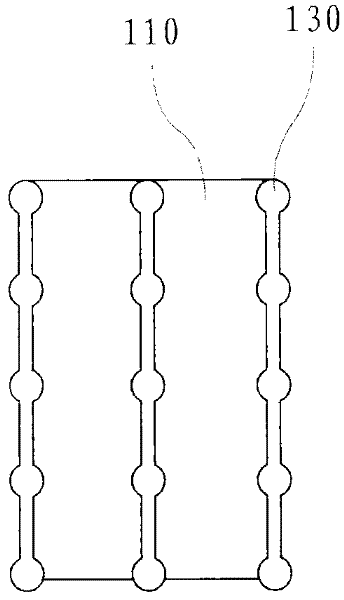

[0017] figure 1 It is a cross-sectional view of placing a packaging substrate in a plastic packaging mold in a double-sided packaging method for an LGA according to an embodiment of the present invention. Figure 2A is true figure 1 The cross-sectional view of the plastic sealing mold in the figure after injection molding is completed. Figure 2B is true figure 1 The top view of the plastic sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com