Semiconductor package and manufacturing method for a semiconductor package as well as optical module

A manufacturing method and semiconductor technology, applied in the field of WLCM, can solve the problem of increasing the number of processing steps or cost, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, preferred embodiments of the disclosed technology are described in detail with reference to the accompanying drawings. It is to be noted that description is made in the following order.

[0024] 1. Embodiment (example of camera module in which electromagnetic light-shielding shielding film is formed on its side and back)

[0025] 2. Modified example (another example of the wiring layer forming step)

[0026]

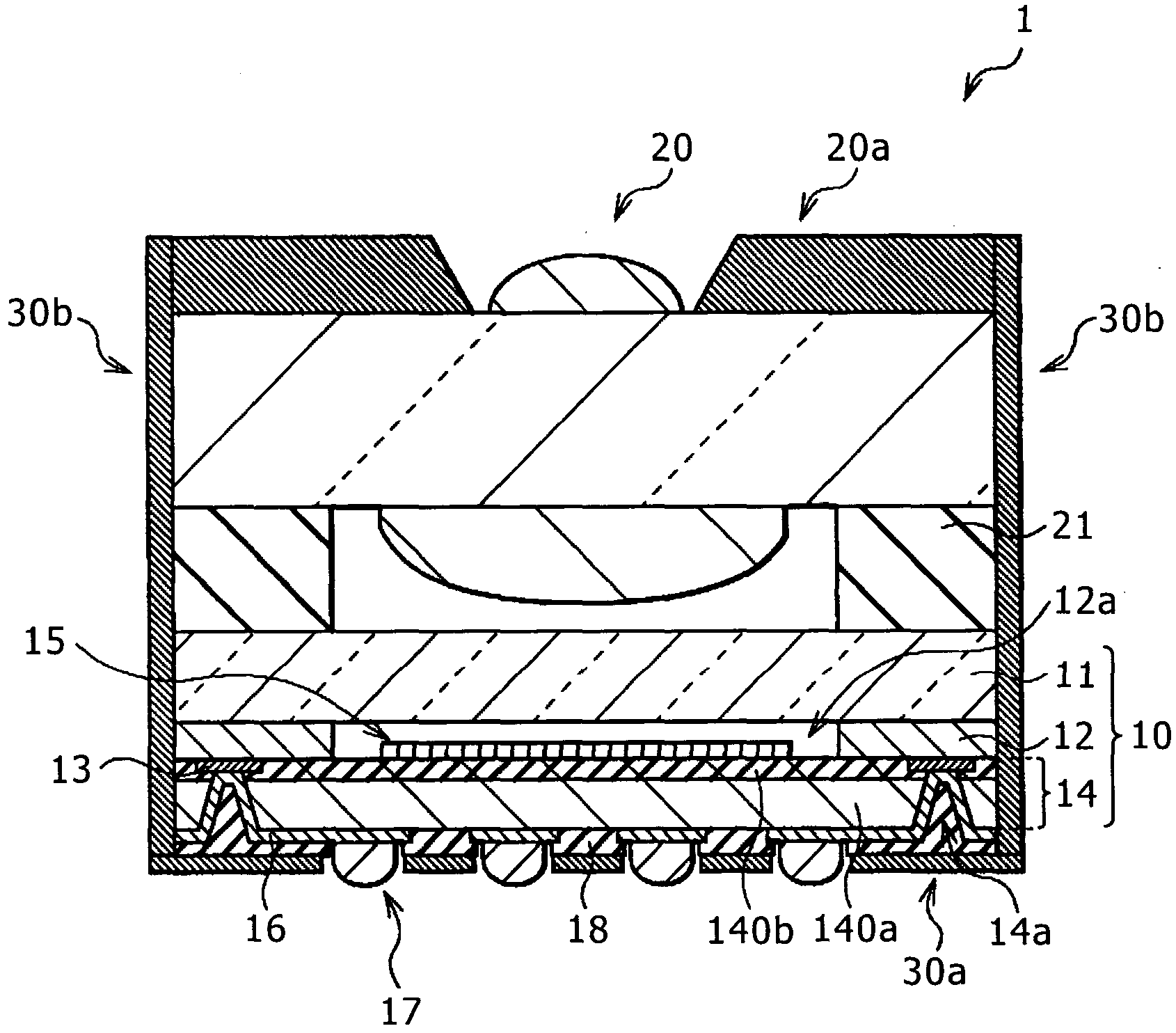

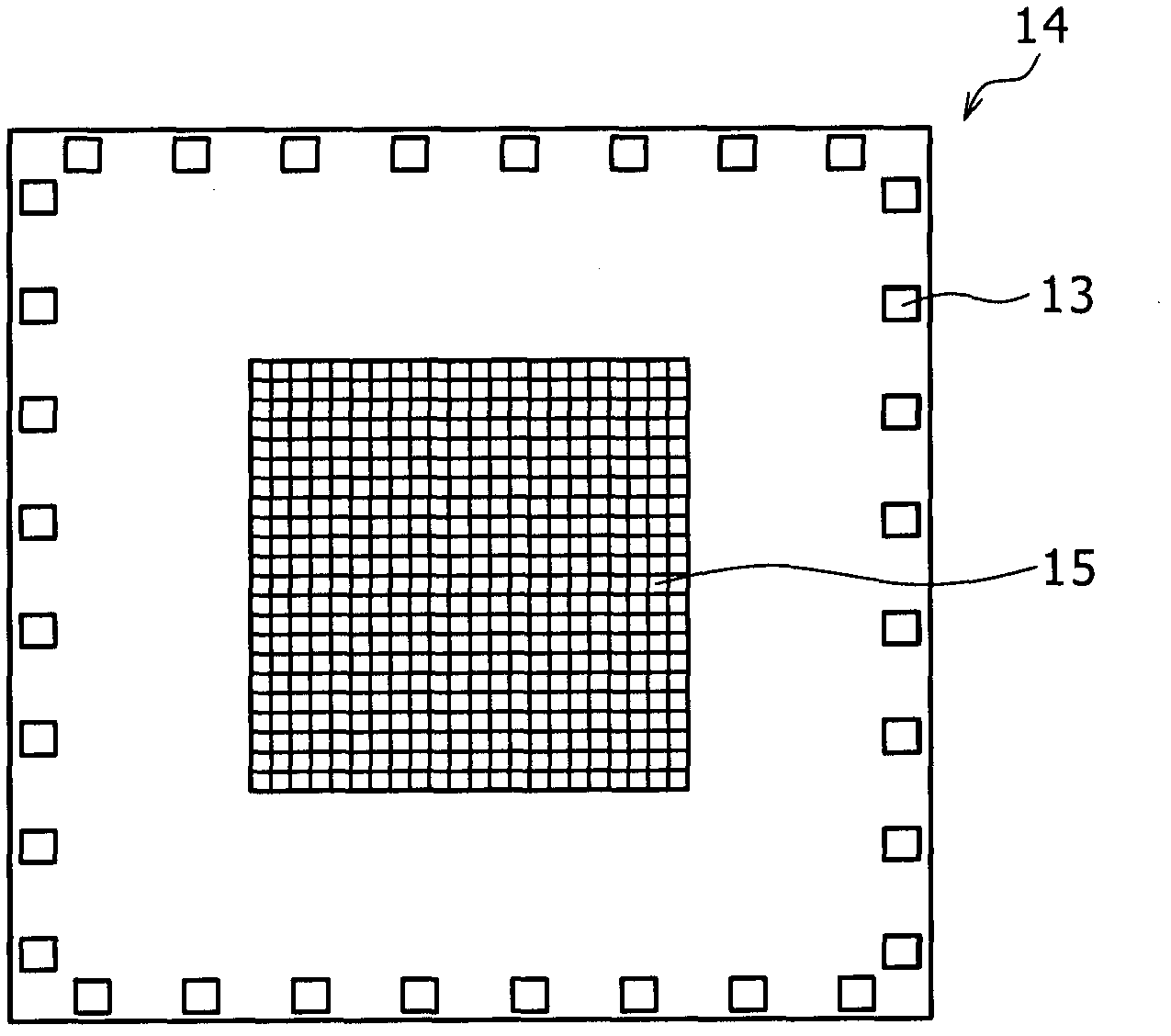

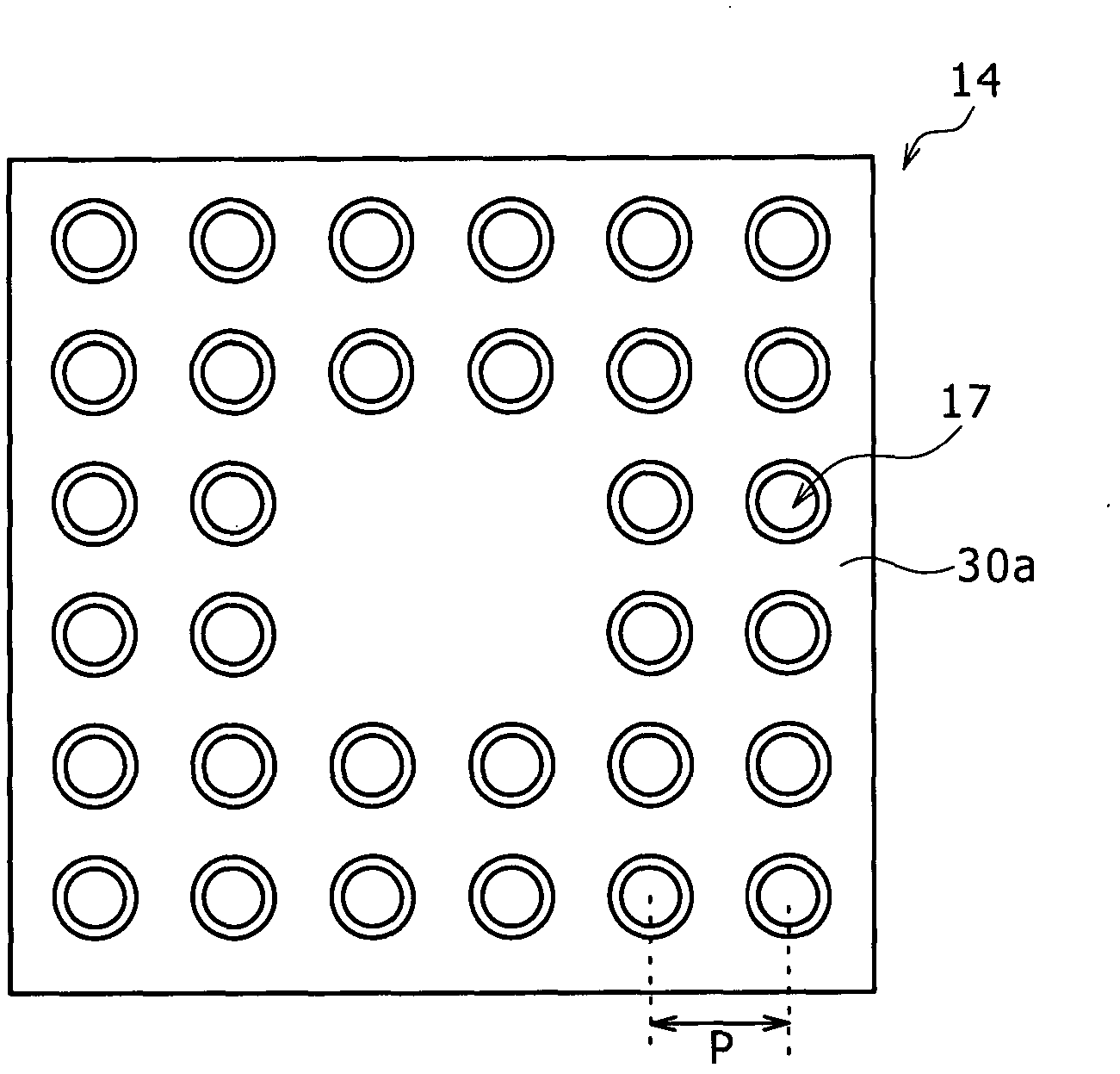

[0027] figure 1 A cross-sectional structure of a camera module 1 is shown, which is an optical module according to an embodiment of the disclosed technology. refer to figure 1 , the camera module 1 is used for an optical device such as an image sensor device and includes a lens unit 20 included in a wafer level package 10 that is a semiconductor package. The camera module 1 is mounted on a printed board such as a motherboard on its lower side (ie, on its wafer level package 10 side) and allows light to enter from its upper side (ie, from it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com